ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

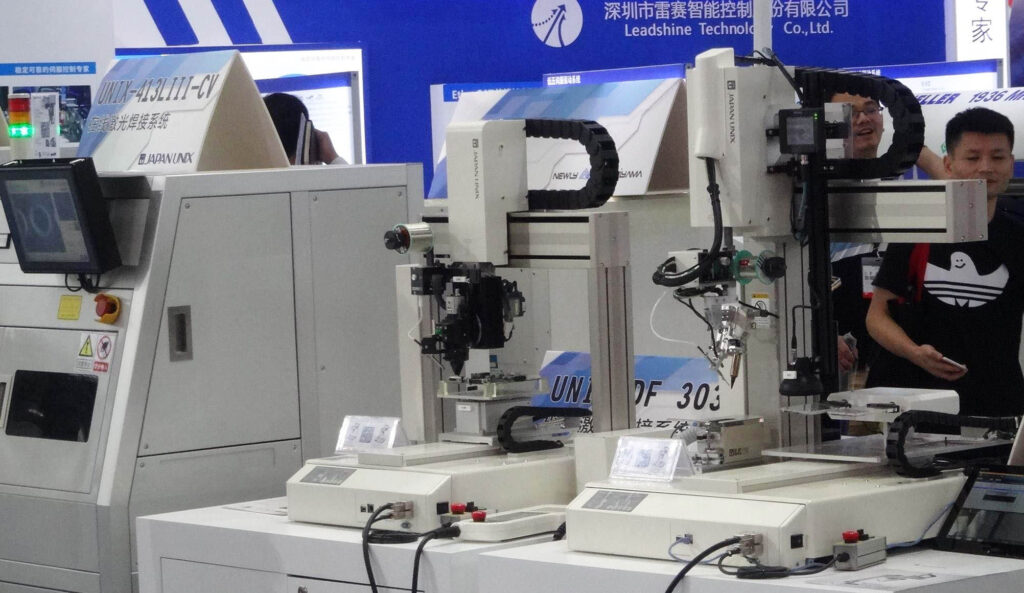

Unique Features Cap Japan Unix New Solder Robots

Japan Unix Co., Ltd. has been increasing its lineup of leading-edge soldering robots. Furthermore, the company also expands software that improves functions, including Soldering Manager.

The company also advances IoT-capable soldering robots. All models support networks.

Undoubtedly, Japan Unix specializes in soldering with soldering robots as its main business.

Flagship Models

The company has brought to the market two models in the FR Series. First, the vertically articulated UNIX-VFR and the horizontally articulated UNIX-HFR, as SOLDER MEISTER. These are the top-of-the-line models for soldering robots.

Japan Unix has commercialized the FR Series as new generation soldering robots designed for full automation production lines. The FR Series features enhanced communication network function to output and accumulate data related to soldering.

It also incorporates comprehensive software that can be used easily regardless of operator skills. With these features, the easy-to-use FR Series soldering robots enable labor savings.

UNIX-VFR suits three-dimensional (3D) mounting leveraging the characteristics of vertically articulated robots and is capable of optimum soldering on angled mounting surfaces. To add internet of things (IoT)-capability, Japan Unix has incorporated communication network function to all models of soldering robots. This feature enables monitoring and tracing of operation status, as well as setting and changing of soldering conditions remotely. UNIX-VFR supports industrial Ethernet (Ethernet/IP).

Bolsters Software Functions

As part of Soldering Solution, Japan Unix has also been bolstering software. Soldering Manager, a soldering robot management software, monitors the status of soldering robots and automatically collects and stores various data. It collects and stores alarm management for the robot/heater and iron tip position correction history during maintenance. During operation, it collects and stores PCB identity code, lot number, heater temperature, feeder records, and iron tip shot counts. Management data includes the number of iron tip shots, number of cycles, the amount of solder feed for single cycle, amount of solder feed for total cycles and robot’s operation time.

Collected data can be used in various ways. It is also possible to store moving images of operation status using an external camera.

Japan Unix has developed Area Laser, a laser irradiation technology for laser soldering robots.

The company has earlier developed the Multi-Phi laser irradiation technology for through-hole terminals. Using this technology allows changes in the outer diameter of the laser beam while it remains circular. Also, the energy can strongly apply to the center (top hat).

The Area Laser technology can irradiate a beam with uniform energy within the laser irradiation range and shapes other than a circle, such as square and rectangle. The technology has expanded the use of laser soldering robots to the surface mount technology (SMT) process.

Area Laser heats the laser irradiation range only instead of the entire printed circuit boards, thereby reducing load on works. It reduces installation space compared with reflow oven. It can also solder multiple spots of flexible flat cables (FFCs) simultaneously, reducing cycle time.

Japan Unix promotes Area Laser as an ideal process for small-lot high-mix production, and the mounting of circuit boards for small devices, such as electronic, mobile and wearable devices, light vehicles and IoT products.