ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

TOWA Expands Molding Equipment Line for Semiconductors

Molding is an important process in the back-end semiconductor manufacturing. TOWA Corporation, as a manufacturer of molding equipment (resin sealing equipment), has been expanding its line to meet diverse needs.

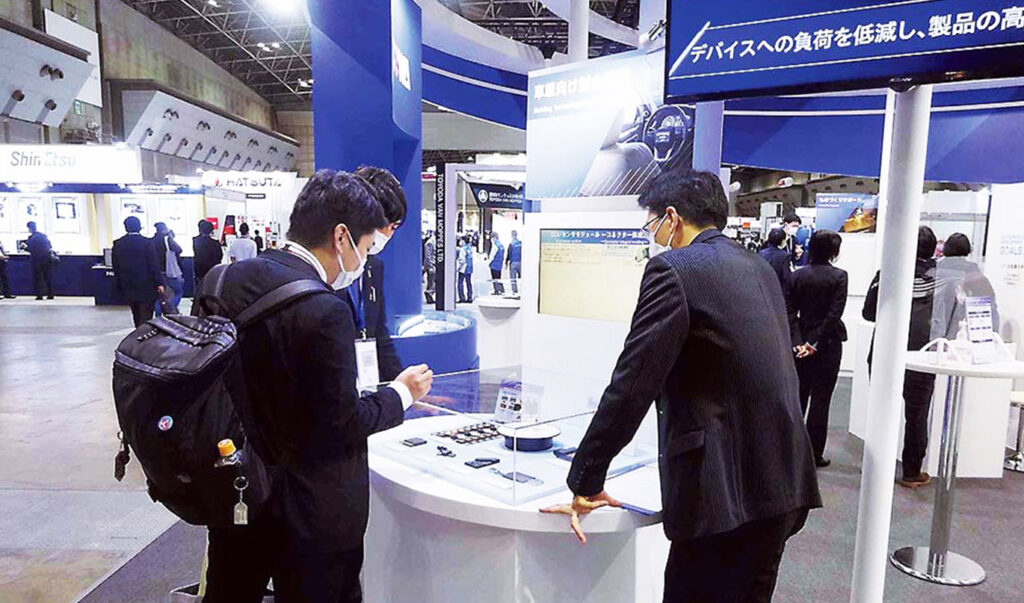

The company proposed molding solutions for leading-edge molding equipment at SEMICON Japan 2021.

Business Areas

Japanese maker TOWA has been deploying semiconductor manufacturing equipment business, focusing on molding equipment, for the global market. It also handles fine plastic molded products, which take advantage of its ultra-precision molding die technology, and laser processing equipment.

The company targets to post sales of 50 billion yen (US$440 million) in the final fiscal year ending March 2024 under its 10-year vision. However, it expects to reach this goal two years earlier than target, resulting from strong business performance.

Molding Equipment

TOWA’s molding equipment meets the needs of the growing semiconductor market. Its products range from 2.5D and 3D leading-edge packages manufactured by wafer-level package (WLP) and panel level package (PLP) methods for internet of things (IoT) and artificial intelligence (AI), to memories/communications devices for mobile devices and 5G communications, and power semiconductors for automotive use.

The company has commercialized equipment that caters to various needs. These equipment adopt larger lead frames and substrates. They feature slimmer dimensions and higher integration of semiconductor devices. Also, these equipment feature increased thicknesses for compatibility with power devices and modularization.

Transfer Molding Equipment

Transfer molding equipment uses the transfer method, in which resin is injected into the molding die and is cured. This method is suitable for individual, double-sided, and exposed packaging of quad flat packages (QFPs), small-outline packages (SOPs), and exposed molded underfills (eMUFs).

YPM Series

TOWA’s lineup of transfer molding equipment includes the YPM Series. It supports various products from discrete devices to electronic control units (ECUs) and power semiconductors. Meanwhile, the EZS Series specializes in high-mix, low-volume production. The series facilitates changeover of molding dies and transfer components models, and contributes to improved productivity.

Compression Molding Equipment

Compression molding equipment uses the compression method, wherein resin is put into the molding die and is melted. Then workpieces are immersed in it, and resin is cured. This method suppresses the flow of resin. It is suitable for batch molding of mold array process-ball grid arrays (MAP BGAs) and mold array process-quad flat non-leaded (MAP QFN) packages. This equipment adopts the cavity down structure, wherein resin is put into the lower mold and workpieces set on the upper mold are immersed in it. It achieves uniform and ultrathin mold even for works with large molding areas.

PMC, CPM, LCM Series

The PMC Series supports strip-shaped works. It adopts the company’s proprietary press structure, achieving high-precision packages. The CPM Series is ideal for resin molding WLPs/PLPs. Meanwhile, the LCM Series is specialized in the sealing of light-emitting diodes (LEDs) and supports molding of 8-inch wafers.

Total Solution Service

TOWA focuses on Total Solution Services (TSS) business. The company provides after-sale services for semiconductor manufacturing equipment and proposes alteration, repair and sales of used equipment.

The company also adopts TOWA LASERFRONT CORPORATION’s welding, cutting, and trimming process technologies that use a new laser technology.

At SEMICON Japan, TOWA proposed optimum molding solutions. It showcased leading-edge transfer molding equipment, compression molding equipment, and singulation equipment. The company exhibited these machines along with samples of memories, communications devices, electronic control units (ECUs) and power semiconductors, focusing on semiconductors for mobile and automotive devices.