ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Silex New Technology Ups Ante for Smart Factory

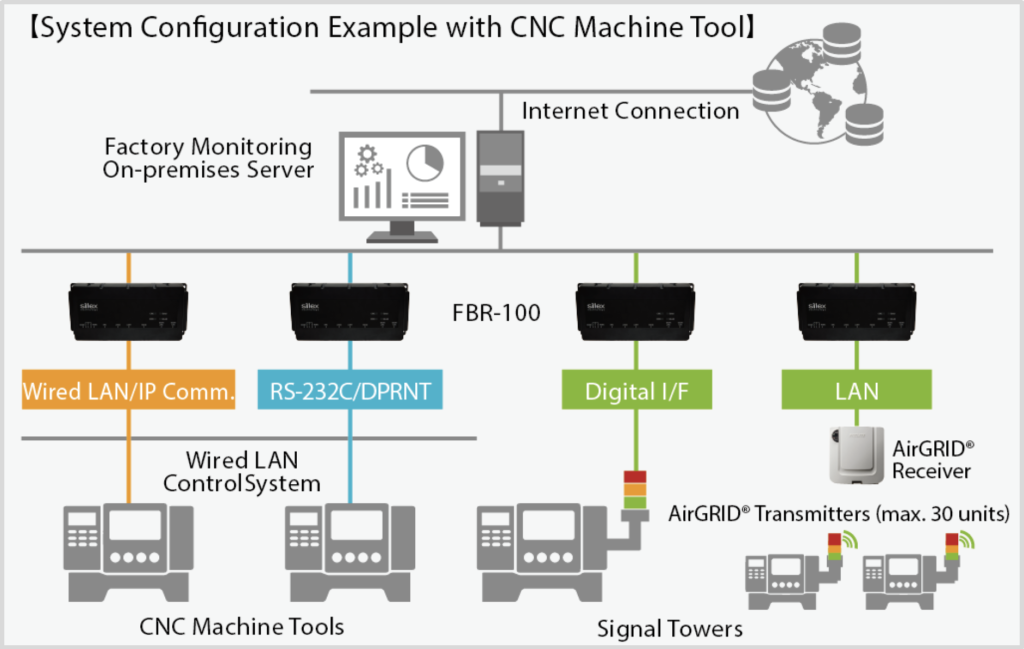

Silex Technology Inc. (Silex) has introduced the FBR-100 wired protocol converter for computer numerical control (CNC) machine tools. To illustrate, FBR-100 collects the operation information of machine tools and transfers the data to the host system over the wired LAN. In addition, this helps factory operators enhance the factory run rate and product quality.

Silex will aggressively promote FBR-100 for factory users and machine tool builders worldwide, especially in China, countries in Southeast Asia, and Mexico. Especially, many Japanese carmakers and electronic component makers are visible in the said markets.

FBR-100 directly connects to CNC machine tools and collects the operation information, like Silex’s current wireless protocol converter FBR-100AN. In addition, the FBR converter series alone enable the host monitoring system, programmable logic controllers (PLC) and human-machine interfaces (HMI) to collect the performance data of machines. The collection is through IoT standard protocols in the machine tool industry, such as MTConnect, OPCUA/umati*1, and Modbus TCP protocol.

The new model provides robust and stable wired communications and enables the smart factory involving overseas factories. Silex has also started providing a function update program that runs on FBR-100AN and FBR-100. The program simplifies the initial setup, provides better help functions, supports more FANUC CNC devices, and collects more CNC information that helps preventive maintenance*2.

FBR-100 Features

The FBR-100 is applicable to FANUC’s and Brother’s CNC devices and other makers’ machine tools equipped with these CNC devices. In addition, it communicates with various communication interfaces and legacy machine tools that do not have a LAN interface. Wired LANx2/RS-232C serial x 1(DPRNT)/digital input

It also supports the industry standard protocols: MTConnect, OPCUA/umati, and Modbus TCP. Meanwhile, it also possesses environmental durability for factory use.

The tool complies with regulatory requirements in Japan, United States, Canada, and the European Union including United Kingdom. Soon, it will also be available in China, Singapore, Malaysia, and Mexico*3.

Future Actions

Amid globalization and stiff competition, Japan, the United States, countries in Europe, and China are strengthening their grit to build next-generation factories. Furthermore, there are increasing demands for integration of machine tool IoT and smart factory systems.

It is now a certain growing trend since COVID-19 pandemic today has increased the necessity for digital transformation (DX) including factory automation and unmanned operation.

Silex will continue to meet customer expectations with its factory products. This includes the new FBR-100 and the current FBR-100AN wireless model certified in Japan, United States, Canada, and countries in Europe. In addition, the company said it will also aggressively promote the integrated solution of these products for factory users and machine tool makers in China, Southeast Asia, and Mexico.

Notes:

*1 Supporting umati interface specifications: OPC 40501-1 UA for Machine Tools ver.1.0 and the necessary functions.

*2 For more details, please download the application note available on the FBR—100 webpage.

*3 The AC power operation requires an AC adapter that has been authorized in countries that use FBR-100. (FBR-100 also operates on 12V – 24V DC powered by a control board of machine tools.)