ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Joint Research Digs Deep on New Tech for 3D Printing

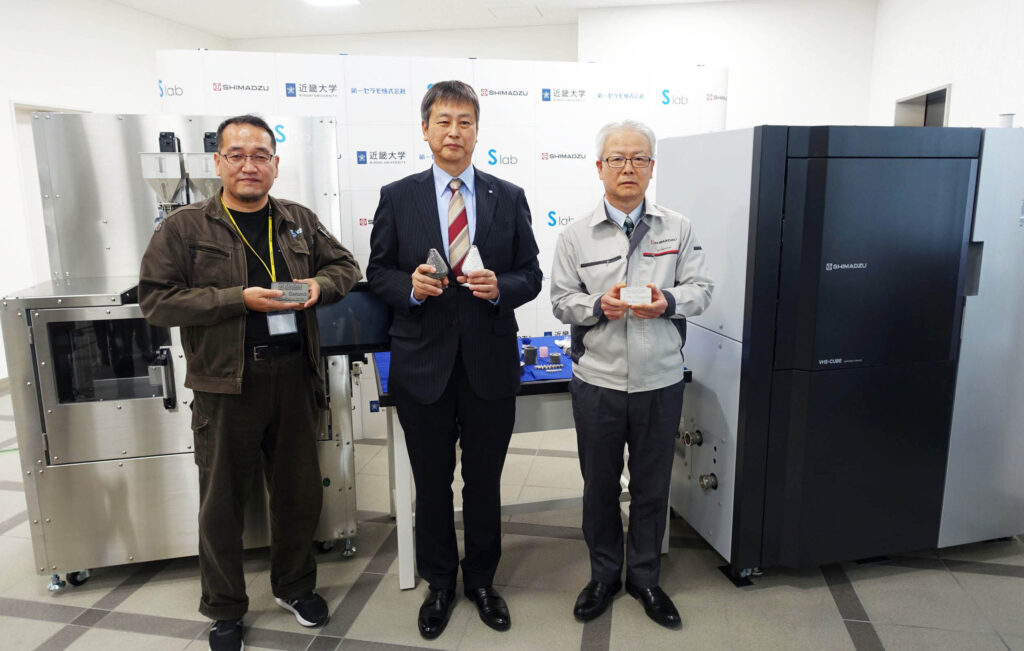

Shimazu Industrial Systems Co., Ltd., a subsidiary of Shimadzu Corporation, Slab Inc., Dai-ichi Ceramo Co., Ltd., and Kinki University, have started joint research on advanced 3D printer. Particularly, the research will zero in on technology that will develop metal and ceramic parts using a material extrusion (MEX) 3D printer.

In the market of 3D additive fabrication of metals and resins using 3D printers, the European market and the United States are leaders in technology and practical application. Nonetheless, Japanese manufacturing companies and universities will try to jointly develop 3D printer systems and move into the market of 3D additive fabrication.

3D Additive Fab

As equipment and component manufacturers, Shimadzu Industry Systems, Slab, and Dai-ichi Ceramo, will actively carry out in the joint development project. Hideki Kyogoku, Professor of Fundamental Technology for Next Generation Research Institute will also join the development group.

Correspondingly, they aim to establish the technology of 3D additive fabrication of metals and ceramics using 3D printers. Shimadzu Industrial Systems is an industrial equipment manufacturer specialized in vacuum heat treatment furnaces, gear pumps, glass fiber winders, liquid feeders, industrial X-ray equipment, etc. Slab Inc. is a manufacturer of machine tools, plastic molding machines, 3D printers, and robots, and produced the first domestic 3D printer (filament type) in 2013. Dai-ichi Ceramo is a group company of DKS Co., Ltd. and a compound manufacturer for powder injection molding. Hideki Kyogoku is an expert in the metal 3D printer technology and will perform evaluation of physical properties and give guidance, by exposing technical problems and suggesting how to improve.

In the next two years, the group will establish the 3D additive fabrication technology for metals using stainless steel and for ceramics using silicon carbide and silicon nitrogen. In addition, the group plans to sell a 3D additive fabrication system composed of a 3D printer and a small vacuum degreasing and sintering furnace. The cost is ¥30 million (US$260,300) per system.

Taps Unique Process

Currently, 3D additive fabrication systems using a metal 3D printer mostly use the powder bed fusion (PBF) method. Here, molding takes place while melting spread metal powder with a laser. The group expects to sell twenty units in the first year at a price which is about ¥10 million (US$86,800) cheaper than conventional systems.

Furthermore, Shimadzu Industrial Systems has already developed a small vacuum degreasing and sintering furnace that can degrease and sinter metal 3D molded objects with size up to 200×200×200mm. Slab Inc. has also developed a MEX method and nozzle-type metal 3D printer with maximum size of 200×200×200mm using a gear pump control system capable of precise discharge control. Dai-ichi Ceramo has also developed metal and ceramic pellets compatible with multi-materials, using its compound technology.

As the first step, the group has started joint development of metal 3D additive fabrication using a compound made by kneading three types of stainless-steel powder, SUS304/SUS316L/SUS630, and a resin binder. The group also confirmed it can mold 3D cylindrical additively manufactured part with diameter of 100mm and height of 150mm in six hours. In addition, degreasing and sintering are both possible in one day.