ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yokogawa’s Proven Flowmeter Offers Remote Maintenance

Yokogawa Electric Corporation has released the VY Series OpreX Vortex Flowmeter. Moreover, these flowmeters comply with major explosion-proof standards and meet SIL2 certification.

The new product series, which is part of the OpreX Field Instruments family, will be released first in India, Southeast Asia, Oceania, the Middle East, and South America, excluding Brazil. It will be rolled out in other markets after compliance with each countries’ standards has been certified. When used in combination with the separately sold specialized software, the OpreX Vortex Flowmeter VY Series supports remote maintenance functions that enable planned and efficient condition-based maintenance.

Development Background

Compared to other flowmeters, Yokogawa’s vortex flowmeters can handle a wider range of fluid, temperatures, and pressures. Moreover, Yokogawa developed the first vortex flowmeter in 1969 and introduced the YEWFLO series of general-purpose flowmeters to the market in 1979. It has so far sold more than half a million units around the world.

Hence, this new series has been developed to support digital transformation (DX) of large plants. This is through efficient and planned condition-based maintenance.

Features, Characteristics

Enables calculations

Utilizing readings from a built-in temperature sensor and data from pressure gauges and other external instruments, the VY Series of vortex flowmeters can perform precise temperature and pressure-compensated calculations*1 and energy calculations*2, eliminating the need for external calculation devices.

Self-diagnostics, condition-based maintenance through DX

The digitalization of internal signals takes further in the VY Series. More importantly, they enable self-diagnostics to cover all components, including the vortex shedder bar and sensor element. Hence, this improves reliability and qualifies these flowmeters for use in safety instrumented loops.

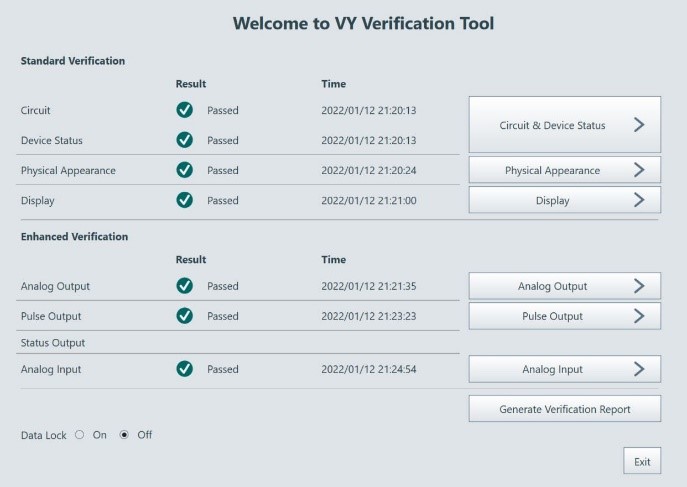

With the VY Series, it is also possible to track device integrity parameters and use this data to indicate when sensor capability is expected to deteriorate. Utilizing the FSA130 integrity verification software tool and the FieldMate device adjustment, configuration, and management application, checking the integrity of VY Series flowmeters is possible.

Consequently, Yokogawa vortex flowmeters have a well-established, maintenance-free reputation. This is because the enhanced self-diagnostics and remote maintenance capability enable an efficient and planned condition-based maintenance.

A unique and proven design

The sensing mechanism, face-to-face lengths*3, and the size range (from 15mm to 400mm), are fully compatible with previously released YEWFLO Series products. Thus, replacing individual devices is possible without the need for additional piping work.

In addition, the vortex shedder bar has a robust and integrated design. It is the only such device in the industry to feature dual built-in flow sensors and a built-in temperature sensor*4. The partial removal or reinstallation of the integrated unit is possible, making it easy to clean or replace parts. Thanks to the use of dual flow sensors and spectral signal processing (SSP) technology, vibration in piping does not affect the vortex shedder bar. Hence, it can capture a stable vortex signal. This design delivers the industry’s shortest vortex flowmeter face-to-face length and reduces upstream straight pipe length requirements.

Propels Sustainable Manufacturing

Kenji Hasegawa, Yokogawa Vice President and Head of the Yokogawa Products Headquarters, says, “We are proud and pleased to release the new OpreX Vortex Flowmeter VY Series. These products are based on Yokogawa’s long history of achievements we have nurtured in this field and incorporate the latest digital technologies. (These make) them even more reliable and easier to use thanks to capabilities such as condition-based maintenance. In recent years, the reduction of energy consumption has become a pressing issue at production sites.”

Hasegawa added the VY Series offers accurate and stable measurement of the flow rate of steam, hot and cold water, compressed air, among others. As a result, he said this will be of great use to Yokogawa’s customers for a more sustainable manufacturing.

Notes

*1 Density of steam and gases change depending on temperature and pressure, leading to measurement uncertainties. The correct flow rate is calculated by using the temperature and pressure compensation.

*2 Displays the instantaneous flow rate, accumulated flow rate, instantaneous heat, accumulated heat, temperature (outward/return), temperature difference, and other measurements required for air conditioning and district heating and cooling systems

*3 Width (the length from end face to end face required to mount the vortex flowmeter on the pipe)

*4 When a configuration with a temperature sensor is selected