ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Solution Realizes Wide-Ranging Smart Manufacturing

Surface-mount technology (SMT) supports the pursuit for customers’ safety and personal satisfaction with the continuing evolution of electronics.

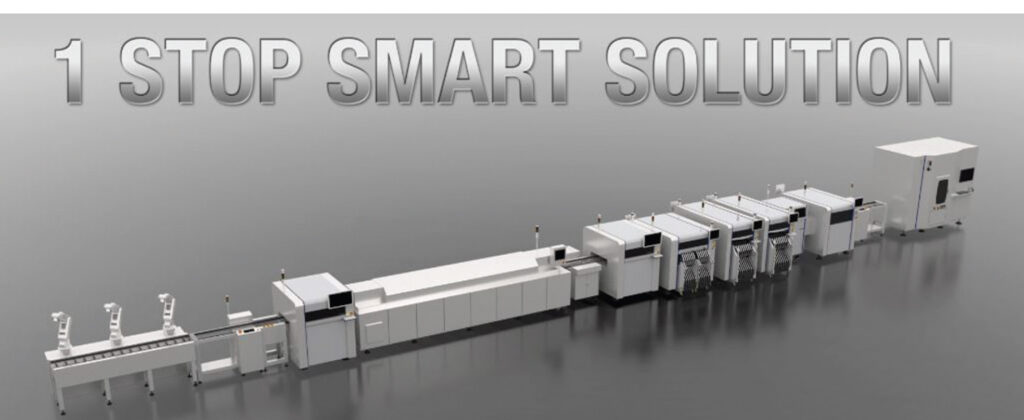

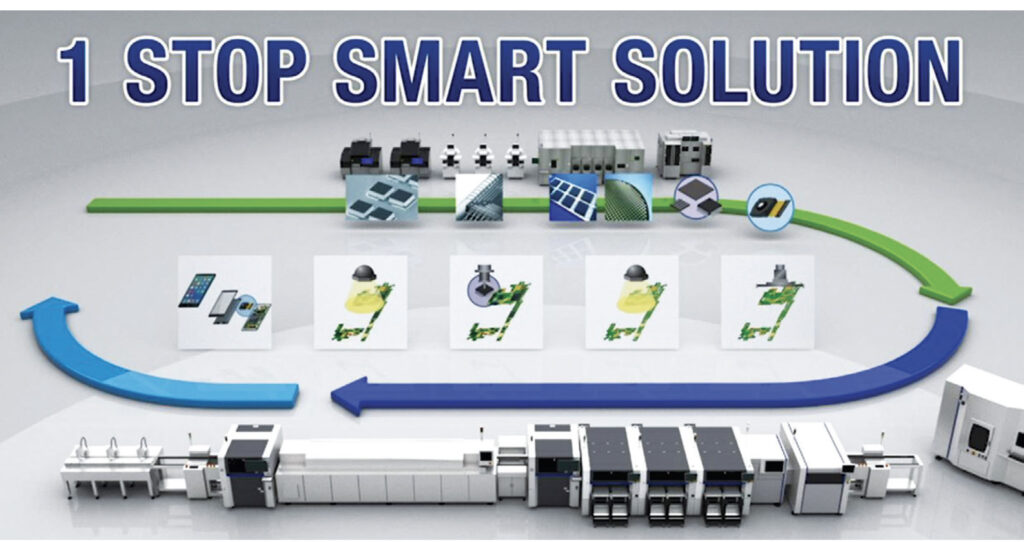

By optimizing its cutting-edge robotics technology, Yamaha Motor Co., Ltd. has developed a full line up of SMT equipment. As its own contribution to the future of electronics, it came up with the “1 STOP SMART SOLUTION” concept (Figure 1).

Solution Concept

To realize the 1 STOP SMART SOLUTION, two conditions must be satisfied: (i) the company has the know-how to collectively develop and manufacture all the main equipment of the SMT production line and (ii) each of these machines must meet high-performance standards.

Using its own smart solution concept, Yamaha has developed and commercialized all major equipment with intelligent functions on the SMT production line. They consist of SMD storage systems, solder printers, dispensers, SPIs, mounters, automated optical inspection (AOI), among others. Furthermore, it has succeeded in giving the highest level of performance in the industry to all of the individual machines. As a result, it has completed one of the industry’s best full lineup system using only the Yamaha brand.

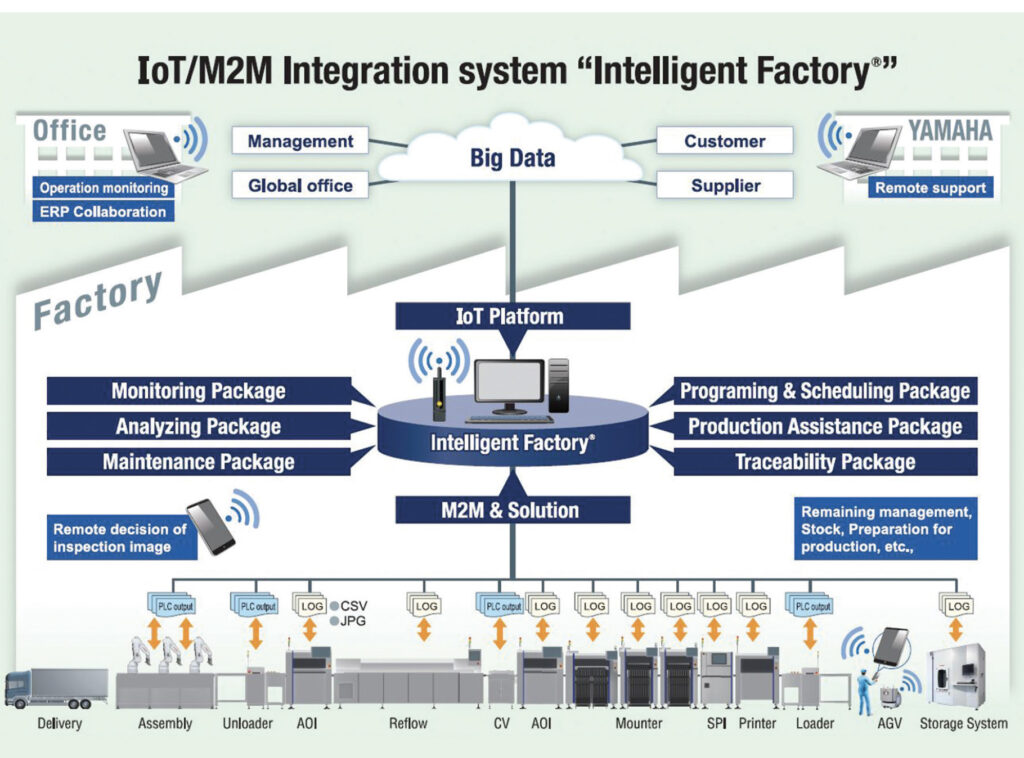

Moreover, Yamaha’s Intelligent Factory concept (Figure 2), an internet of things (IoT)/machine-to-machine (M2M) integrated system, uses the latest IT technology and will connect machines through advanced M2M cooperation. This does not require a black box and is only realized by machines from the same brand. This embodies the ideal concept of 1 STOP SMART SOLUTION by maximizing the capability of the line through the combination of hardware and software functions. This system will strongly promote smart manufacturing of SMT factories.

Latest Functions of 1 STOP SMART SOLUTION

Below introduces the latest functions and mutual cooperation between Yamaha’s SMT equipment and the “Intelligent Factory” which continues to evolve.

Production planning and operation processes: New software YSUP-PG

1) New GUI

The user interface has been redesigned. The layout has been carefully chosen to be best suited for intuitive operation. The operation can be easily performed by beginners and efficiently by advanced users.

2) CAD, CAM, and Gerber data conversion

Not only ASCII CAD data but also standard CAM data can be converted into implementation data. In addition, it is possible to generate production board images with high accuracy from Gerber data, supporting accurate data construction.

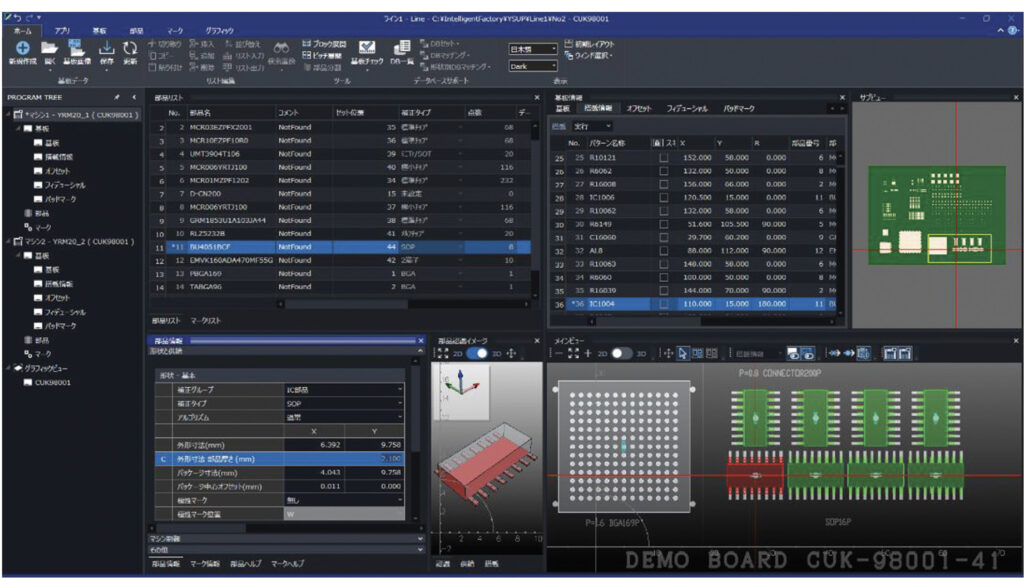

3) Visual editor (Figure 3)

It displays images generated from standard CAM data and Gerber data, enabling accurate prior confirmation of the mounting position and mounting angle. In addition, it enables automatic measurement of the component dimensions from their actual image. The correction work which is time-consuming in conventional methods can be performed without so much skill by thorough checking on the graphic screen.

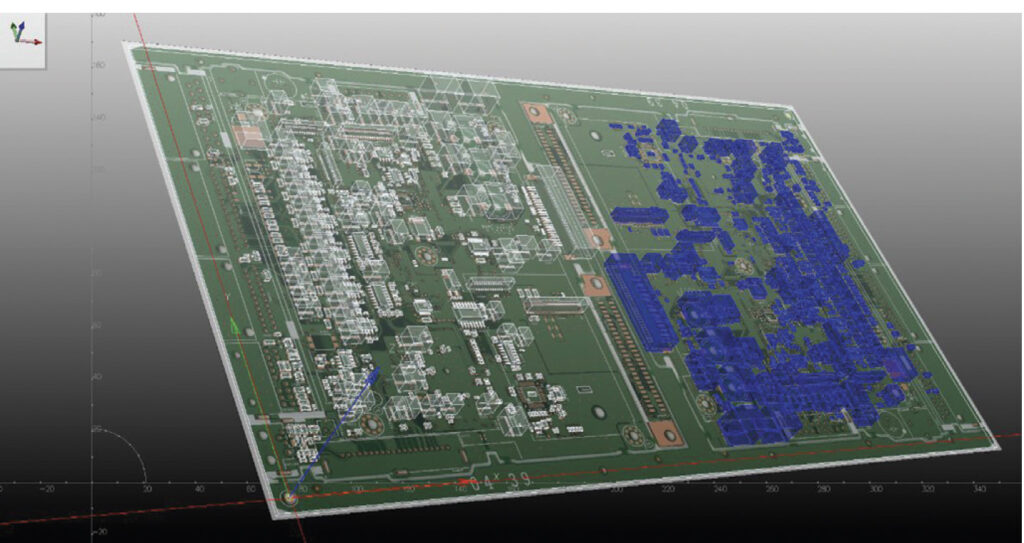

4) 3D graphic view (Figure 4)

It is possible to accurately check component interferences and mounting coordinates with a 3D image, improving the quality of the board data.

5) Grouping

At actual sites of a factory, where there are many setup changes, the combination of common components is automatically calculated, determining the appropriate order of the most efficient production. Furthermore, the most efficient order is calculated in consideration of the switching time due to the temperature profile change in the reflow process. The setup time and waiting time can be minimized, improving work efficiency and productivity. It also supports dual lanes.

Setup and supply process

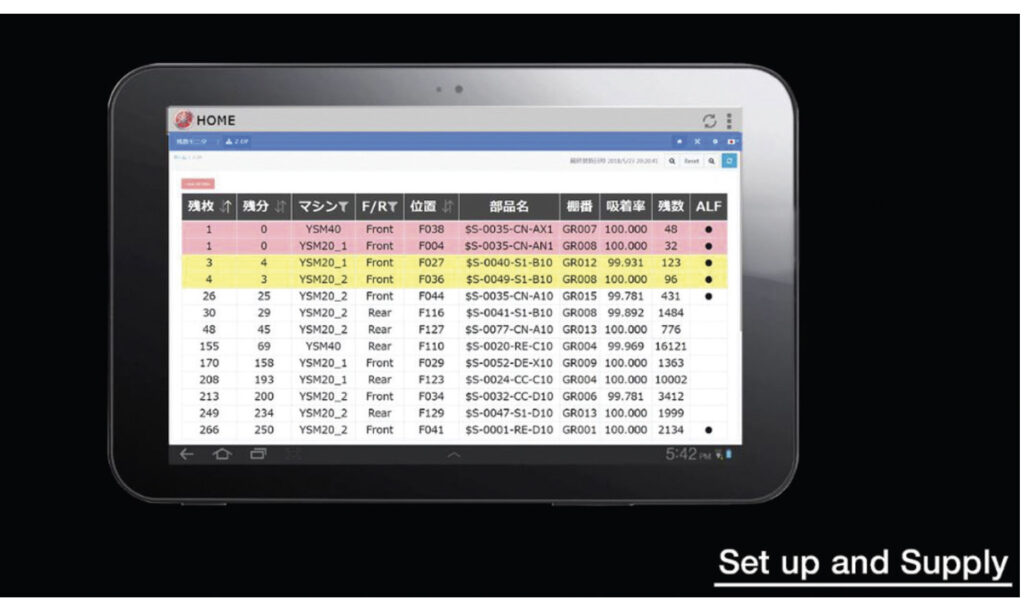

1) Component remain monitor (Figure 5)

It is possible to check the components delivery information at a remote location using a tablet or a mobile phone and to find the timing of replenishment.

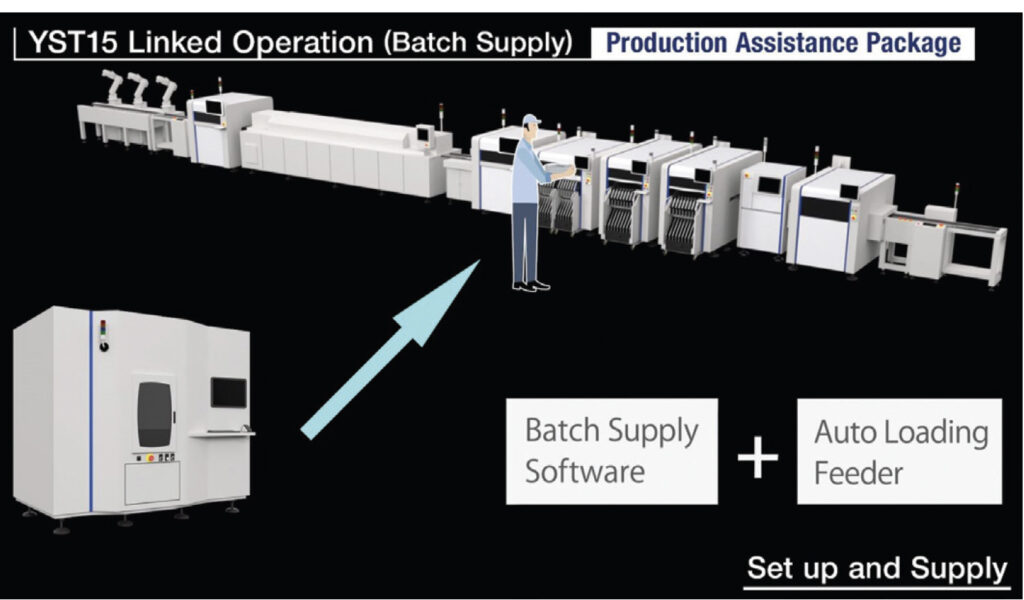

2) Batch supply (Figure 6)

By combining the SMD storage system YST15, the auto-loading feeder that can preset the next reel, and the batch supply software, necessary components can be shipped out together at the required timing and components can be replenished all at once without stopping the machine. The number of patrols of the operator is drastically reduced and the work efficiency is greatly improved. In addition, automatic components transportation is possible in cooperation with AGV.

3) New IT-System

A system that centrally manages information on components and materials for the entire floor and works as the basis of various optional functions. Real-time high-speed response is realized. The response when only a single unit is connected is possible, even if 100 units are connected. Highly reliable cooperation is realized with peripheral devices and higher-level systems.

(3) Software contributing to quality

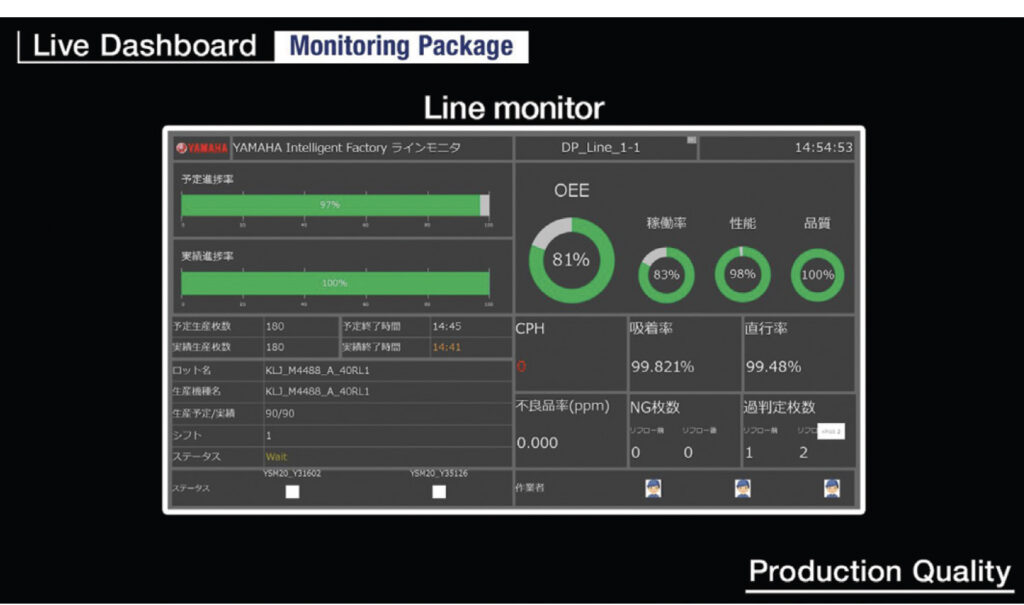

1) Live dashboard (Figure 7)

The operating status of the entire floor and each line can be monitored in real time on a chart.

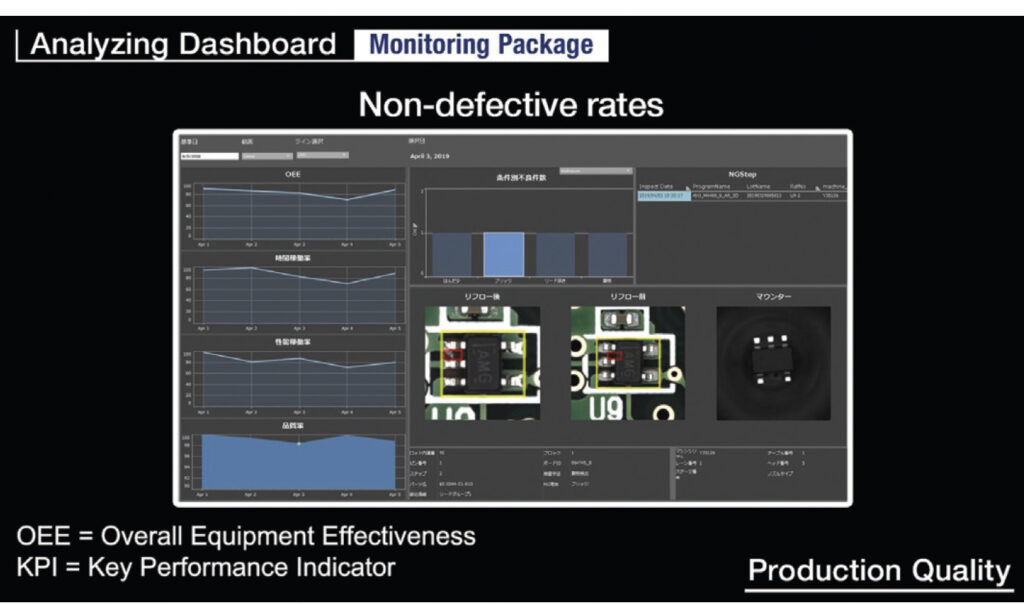

2) Analyzing dashboard (Figure 8)

This visualizes production progress and achievements, OEE, and KPIs, and supports problem analysis.

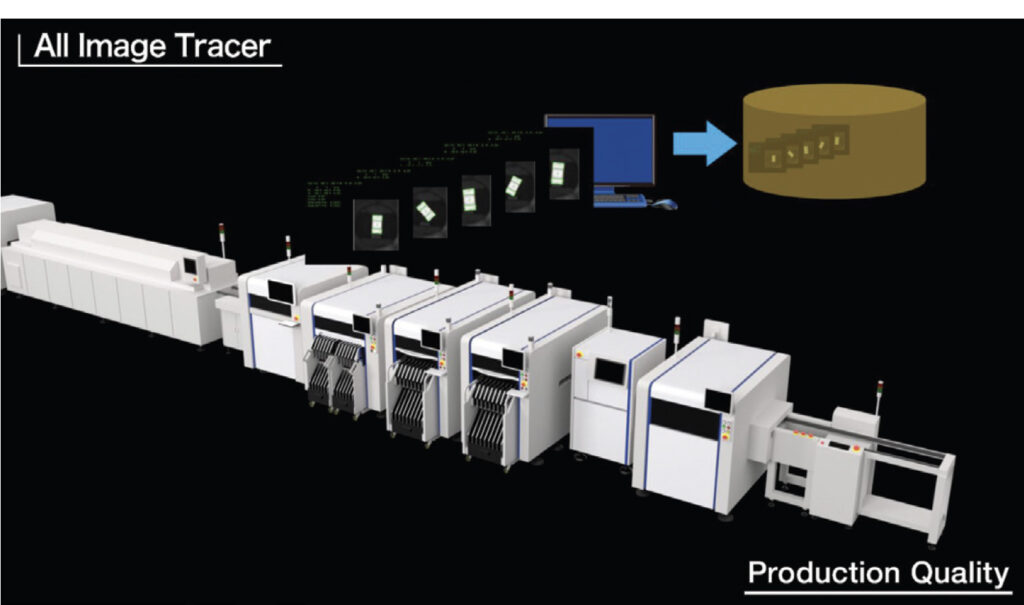

3) All image tracer (Figure 9)

It saves all collected images of components on the mounter. The search for the desired image can easily be performed with the viewer application, enabling quick identification of the cause of a defect.

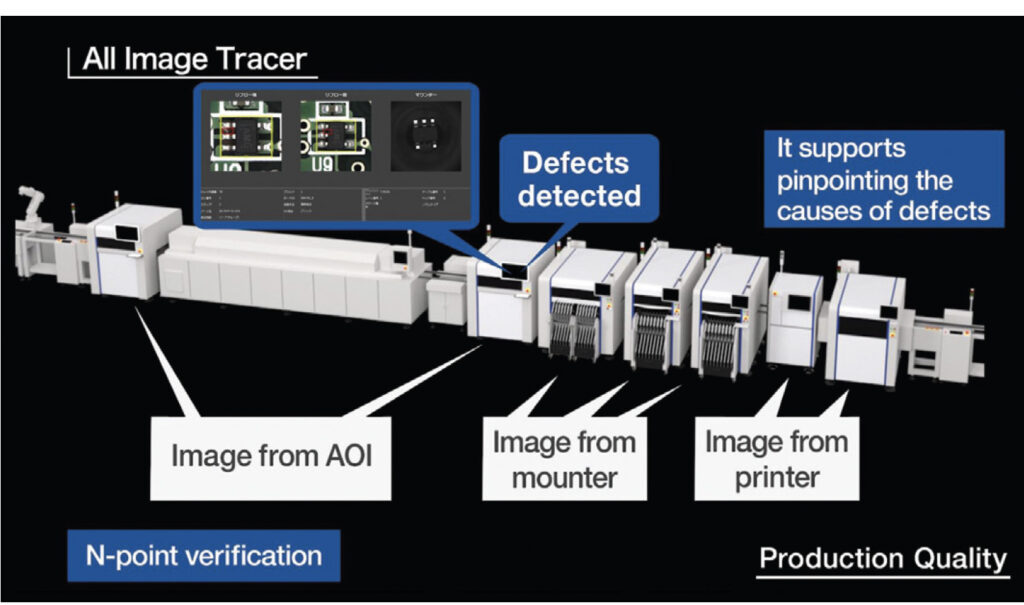

4) N-point verification (Figure 10)

Following the visual inspection before and after the reflow, the image and information related to the mounter and printer can be compared with each other, enabling quick identification of the cause of a defect at the NG mounting point.

Conclusion

Yamaha aims to sublimate the 1 STOP SMART SOLUTION concept into the Yamaha brand robotics business concept. Therefore, in addition to the well-established backbone of the SMT business and the FA business of industrial robots, the company established the businesses integration with Shinkawa Ltd., APIC YAMADA Corporation, and PFA Corporation. This resulted to the establishment of Yamaha Robotics Holdings Co., Ltd. as a total solution provider originating in Japan.

The company will continue to build a system that makes it possible to quickly provide advanced total solutions. It will tap 1 STOP SMART SOLUTION for the integration of processes from the semiconductor post-process and the surface mounting process to the product assembly, which are expected to become important in the future (Figure 11).

About This Article:

Yamaha Motor Co., Ltd. provided the contents of the article.