ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Toshiba Employs New Technology in Detecting Scratches

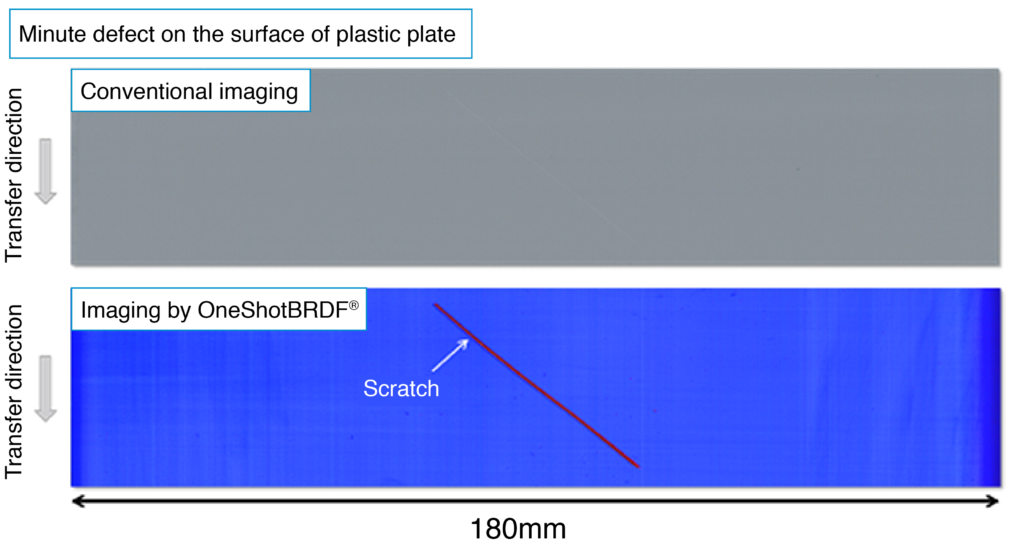

Toshiba Corporation has announced the development of a new technology for visual inspections on production lines. To illustrate, the new optical inspection technology enables real-time visualization of micrometer-size minute defects. Particularly, defects such as scratches on the surface of products with a wide imaging visual field.

The company expects the implementation of the technology as part of solutions.

Propels Introduction of DX at Manufacturing Floors

OneShotBRDF, Toshiba’s new optical technology for visual inspections of production lines on manufacturing floors suits line scan cameras. It makes line scan cameras obtain full visual field. In addition, the mechanism of the camera has been devised to visualize defects. Thus, the system may be able to help solve the labor shortage issue and dependence on manpower on manufacturing floors. At the same time, improve productivity, taking advantage of digitization.

At the production site, the labor shortage issue has become tangible amid the ageing of skilled workers. Automation of visual inspection has been one of the apparent issues. Thus, it is difficult to discriminate minute defects on the product surface with high accuracy in real time without stopping transfer.

In the automation of visual inspections on production lines, cameras are the mainstream methods to analyze images. Cameras come either as scan cameras that capture the target by area and line scan cameras that capture the target line by line. Area scan cameras can easily obtain two-dimensional images. However, it is difficult to apply them to visual inspections on production lines, where products continuously flow at high speeds.

Meanwhile, line scan cameras can obtain and process continuous images along the transfer direction and adjust sensitivity of individual pixels in detail. Hence, they have been introduced in many mass-production sites.

However, while line scan cameras can capture images of micrometer-size defects, the resolution has poor contrast of light and dark. Hence, it is difficult to clarify those defects from captured images. For that reason, skilled workers are necessary to carry out visual inspection and touch examination in order to require discrimination of minute defects.

Development of New Technology

In 2019, Toshiba developed a one-shot optical inspection technology for area scan cameras. This technology identifies the light scattering angle by color using color filters and instantaneously visualizes minute defects. Particularly, the company has looked into the development of inspection technology suitable to line scan cameras in light of their wide use in production sites.

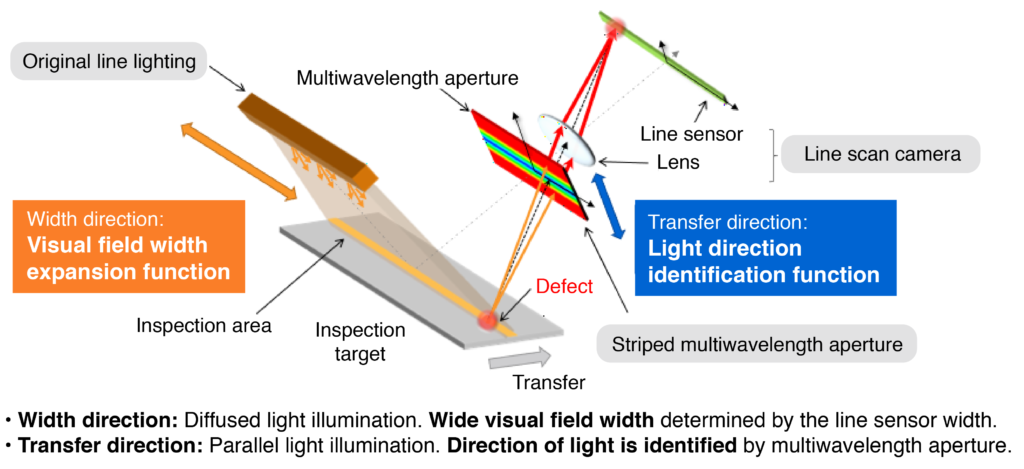

The optical system of OneShotBRDF consists of original lighting with parallel light in the transfer direction and diffusion light in the width direction. In addition, a striped multiwavelength aperture installed in front of the line scan camera’s lens. The irradiation of light to a smooth inspection target with no defects, the light maintains parallel state in the transfer direction.

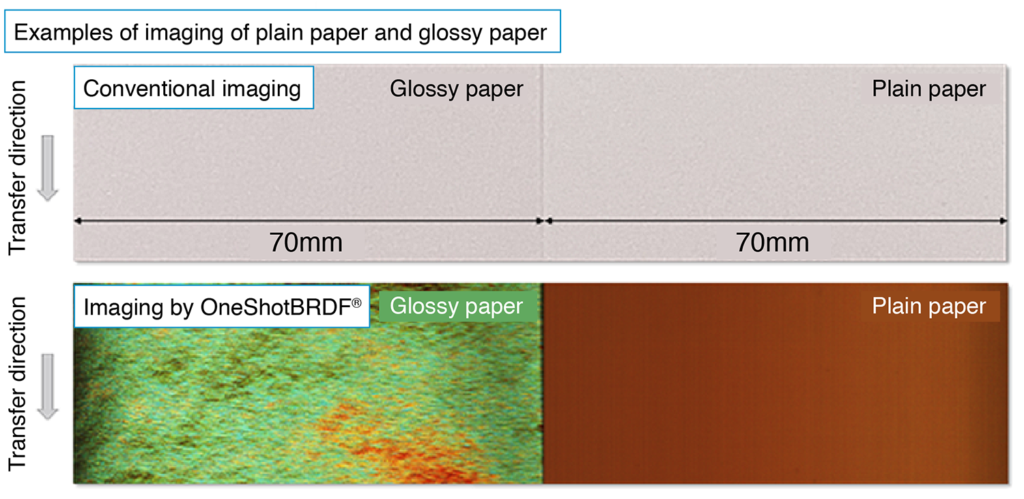

When there is a defect, illumination light scatters to various directions, enabling clarification of the defect. The light in the width direction is diffusion light, enabling imaging in a wide view field without being limited by the effective diameter of the lens. Furthermore, it sharply identifies minute defects by colors over a wide view field of the line scan camera.

Furthermore, the company’s proprietary analysis technology, which handles pixels of obtained image as vectors of an RGB color space, has enabled automatic identification of minute defects.

With these features, OneShotBRDF enables high-accuracy visual inspection of products transferred on production lines in real time. Toshiba Digital Solutions Corporation plans to put to market the technology as an image inspection solution product.