ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SEMICON China Gears up Region’s Might in IC Production

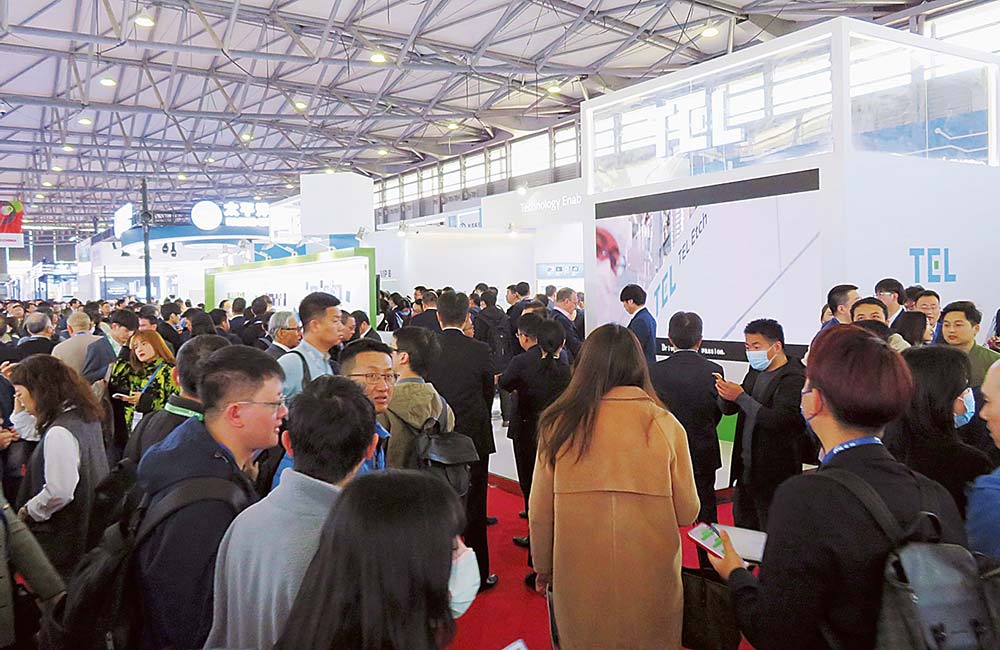

Semiconductor manufacturing equipment trade fair SEMICON China 2024 successfully staged its annual event from March 20 to 22. Accordingly, the event took place amid the growing semiconductor manufacturing industry in the region. Thus, interest in semiconductor manufacturing equipment and materials keeps getting better year after year.

Among others, the event drew success because of the synergies with productronica China 2024, which also took place after SEMICON China, as well as LASER World of PHOTONICS CHINA.

Approximately 1,150 companies from countries and regions around the world exhibited at this year’s SEMICON China. Moreover, the exhibition space expanded to a scale exceeding that of the previous year.

Banks on Local Demand

Demand for semiconductor production equipment is rising in China. Particularly, amid the Chinese government’s policy of domestic self-sufficiency in semiconductors. Furthermore, the trade friction between China and the United States has also affected manufacturing equipment importation into China. Nonetheless, exhibitors showed off their focus products for China as well as their strengths.

Last year, the semiconductor production equipment market remained sluggish. Moreover, the industry expected a 6.1 percent year-on-year decline based on SEMI’s forecast, a reversal from the record-high global sales of US$107.4 billion in 2022. By region, while all countries and regions were below the previous year’s level, only China grew at a much faster rate than the previous year.

Nonetheless, the need to increase the ratio of semiconductor manufacturing in China has been propelling local demand. In addition to government-supported projects, local Chinese foundries and device makers are building new factories and investing in new facilities in various regions, and demand for semiconductor production equipment is gaining momentum.

Against this backdrop, Japanese exhibitors also presented a variety of products for the Chinese market. In addition to various types of equipment for front-end and back-end processes, Japanese players also featured wide range of technologies. This includes products for power semiconductors that support electric vehicles (EVs) and robots.

Japanese Players Flex Muscle

SCREEN Semiconductor Solutions Co., Ltd. introduced the SU-3400, a single-wafer cleaning system for 300 mm wafers. Particularly, the SU-3400 has more chambers than its predecessor to increase productivity. The SU-3400 contributes to improved throughput as semiconductor manufacturing processes become more complex.

Despite the export restrictions of the United States, the company said it did not have direct impact to them. If some functions of the company’s products are subject to the regulations, the company is responding by removing the targeted functions.

On the other hand, KOKUSAI ELECTRIC Corporation proposes film deposition process equipment and treatment (film quality improvement) process equipment. Accordingly, the company’s strength lies in its batch-type ALD (atomic layer deposition) technology, which supports the increasingly difficult film deposition process of miniaturization and three-dimensional layering.

Masami Miyamoto, Corporate Vice President and Executive Officer in charge of sales, commented, “Semiconductor manufacturing in China is on the rise, and inquiries are strong. In China, there is strong interest in ALD technology for uniform deposition of high-quality films with good step coverage.”

Growth Drivers

Recently, the production of power semiconductors in China has been increasing rapidly. This as the demand for these devices grows against the backdrop of the expanding use of EVs. In addition to IGBTs, the number of manufacturers of compound devices such as SiC and GaN is increasing.

Relatedly, Nikon Corporation introduced its i-line lithography system NSR-2205iL1, which got its market release last year. In addition to power semiconductors, the NSR-2205iL1 can be used for RF devices, MEMS, and various other devices. The response to the announcement has been strong. Thus, the company received several inquiries from show visitors at their booth. The company plans to release the product this summer.

Meanwhile, Lasertec Corporation exhibited a panel display of its SICA88 SiC wafer defect inspection/review system and GALOIS211 GaN wafer defect inspection/review system for power semiconductors. Koichi Moriizumi, Director and Senior Managing Executive Officer, said, “The number of SiC and other power semiconductor manufacturers is increasing in China, and inquiries have been strong for some time.”

On the other hand, SINFONIA Technology Co., Ltd. exhibited a load port installed at the front of semiconductor manufacturing equipment to load and unload wafers. The 300mm FOUP-compatible load port has been introduced at the end of last year. This year, it garnered great attention when unveiled in China.

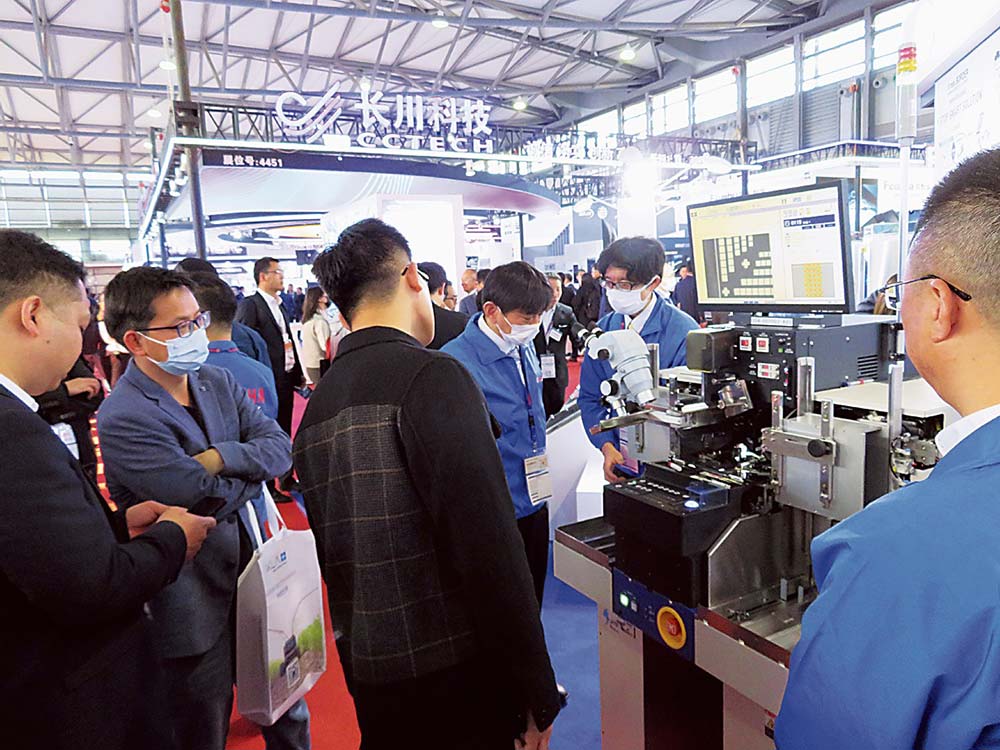

Fasford Technology Co., Ltd. exhibited at the Jipal booth of its distributor, Fasford Technology Co., Ltd. attracted much interest with an actual exhibit of its versatile die bonder, DB820.

Meanwhile, other exhibitors included Tokyo Electron Limited, DISCO Corporation, THK Co., Ltd., Toray Engineering Co., Ltd. and Yamaha Robotics Holdings Co., Ltd.

Demand for semiconductor production equipment and materials is expected to remain high in the Chinese market, and a full recovery in the global market is expected in the second half of 2024. Japanese companies will accelerate their efforts in the Chinese market.

*This is an English translation of a Japanese article originally published in the March 27, 2024 issue of Dempa Shimbun Daily.

–27 March 2024-