ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Resonac to Boost Innovative Tech for Best IC Materials

Resonac Corporation has introduced a new simulation technology, a neural network potential (NNP) for material development.

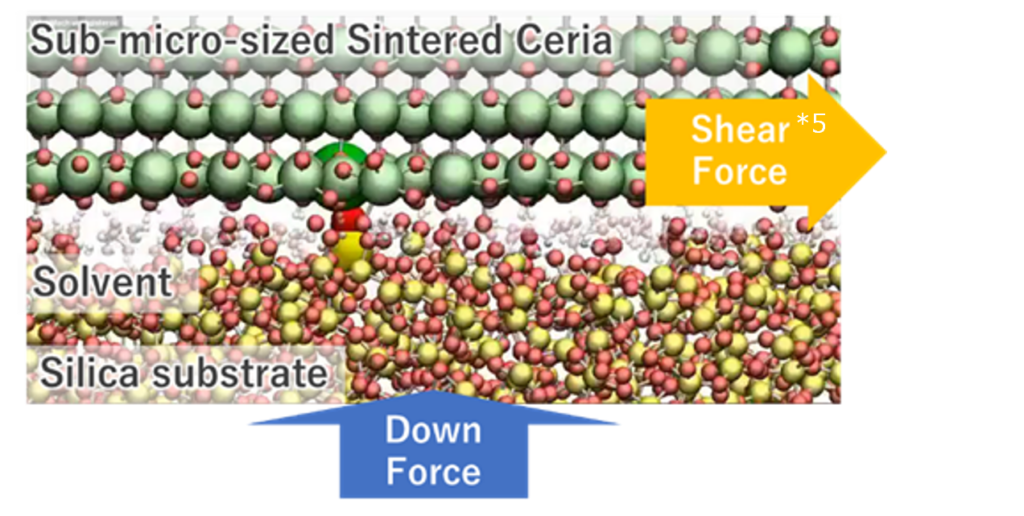

Accordingly, the new simulation technology combines the first-principles calculation method commonly used in simulations for material development and artificial intelligence (AI). Specifically, it aims to simulate and elucidate the semiconductor circuits polishing mechanism using CMP slurry*1. This technology is the first of its kind in the world.*2

NNP technology is capable of the previously difficult feat of simulating chemical reactions more than 100,000 times faster while maintaining the same level of accuracy as first-principles calculations. This technology will enable Resonac to elucidate the behavior of materials occurring in the complex semiconductor fabrication process and rapidly create new materials.

Responds to Market Needs

Recently, the speed of technological innovation in the semiconductor industry has been accelerating. Thus, there is a need to provide new materials quickly. Efforts are underway to accelerate the creation of new materials through efficient R&D by conducting experiments after simulation for rough estimation. For semiconductor fabrication processes, however, it is necessary to calculate the interactions at interfaces between materials with different properties, such as inorganic, metallic, and organic materials. In these cases, the use of first-principles calculations have become common. While this method can produce highly accurate calculation results, calculations consume a large amount of time and computing power. Therefore, it is difficult to simulate mechanisms while taking into account complex chemical reactions and the surrounding environment, such as pressure.

In addition, the limited reaction time available for analysis makes first-principles calculations unsuitable for semiconductor materials. Among them, the polishing process of semiconductor circuits using CMP slurry, which is crucial for semiconductor manufacturing, involves the presence of many molecules and atoms such as additives and abrasives.

Moreover, it requires fine control of the complex geometry of the substrate, necessitating large-scale simulations both temporally and spatially.

Role of AI Semiconductors

For several years, Resonac has been studying the introduction of NNP technology to semiconductor materials development. Specifically, the performance of AI has been dramatically improved by using AI semiconductors.*3

“This state-of-the-art NNP technology allows us to train the AI model with tens of millions of data points from first-principles calculations and perform large-scale simulations with a high degree of accuracy comparable to first-principles calculations. With NNP technology, calculations that would take more than 1,000 years with first-principles calculations can be completed in 100 hours,” the company said.

Resonac adopted state-of-the-art NNP technology to simulate the polishing process of semiconductor substrates using CMP slurry. As a result, Resonac successfully visualized complex interface behavior precisely on a nanometer*4 scale. Thus, allowing the company to understand intricate polishing mechanisms that are difficult to capture through experiments alone.

15 August 2024