ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Polyplastics Promotes Green Society in New Material

Polyplastics Co., Ltd., a leading Japanese provider of engineering plastics and polymers, has been advancing the research and development (R&D) of products that reduce environmental impact while maintaining the performance demanded by the market to create a recycling-based society. Primarily, the company’s new DURACON® POM short cellulose fiber reinforced grades currently in development are products that meet market needs such as these.

Uses Regenerated Cellulose Fibers

Particularly, cellulose is a non-edible bio-based material that contributes to a sustainable society. Currently, it is drawing significant attention as a carbon-negative material that absorbs carbon dioxide in the atmosphere. In the development of DURACON® POM short cellulose fiber reinforced grades, the company used regenerated cellulose*1 manufactured through a solvent method that produces hardly any waste. This manufacturing method with low environmental impact can also reduce carbon dioxide emissions.

Makes Both Lighter Weight and High Rigidity Possible

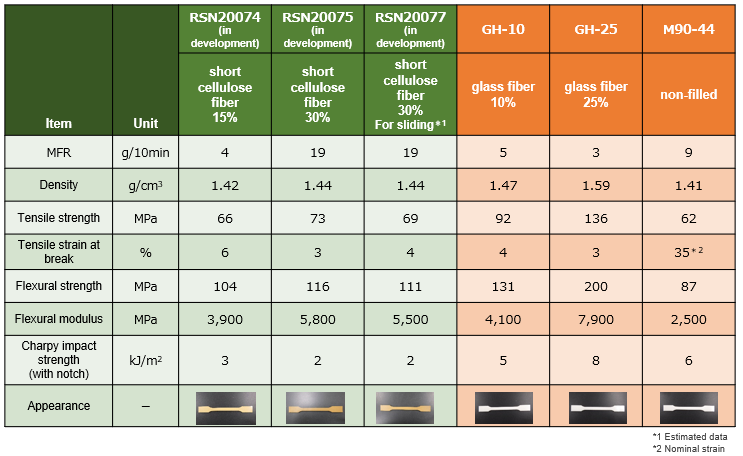

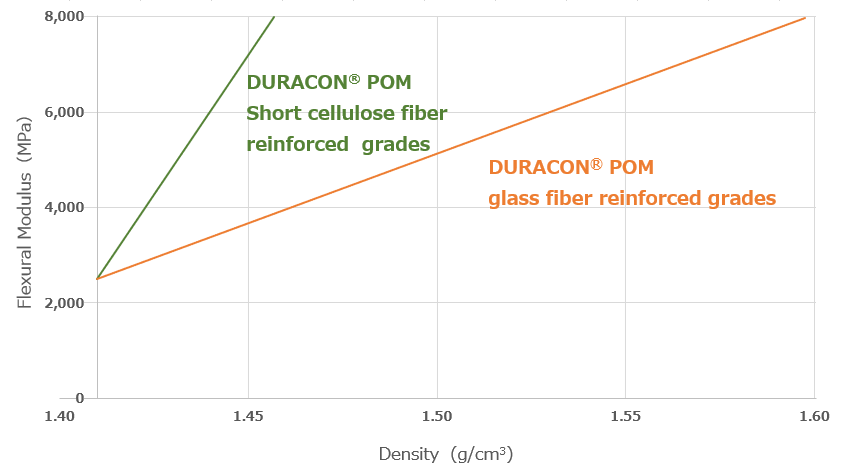

Mainly, DURACON® POM short cellulose fiber reinforced grades have the characteristics of light weight and high rigidity. Although mechanical properties improve when using glass fibers, which are widely used as resin-reinforcing material, the high specific gravity of glass causes a significant rise in the density of the composite. Conversely, flexural modulus can be increased without significant increases in density when using cellulose fiber as resin-reinforcing material.

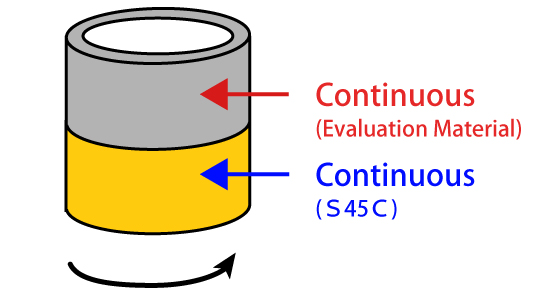

Maintains Superior Sliding Properties Inherent to POM

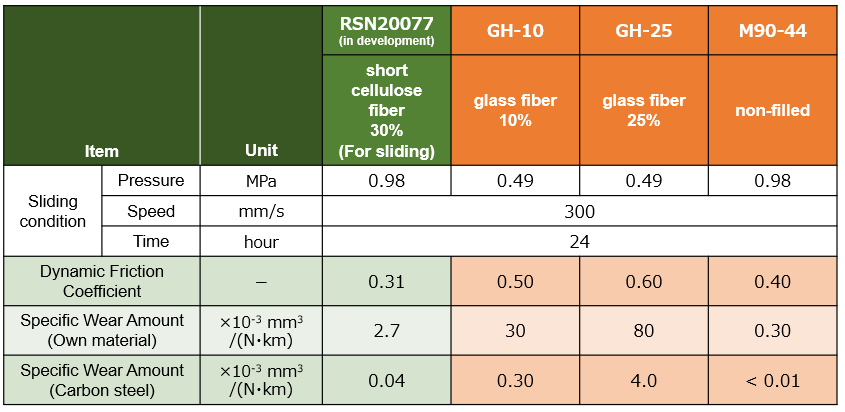

Additionally, superior sliding properties are a characteristic of POM. However, when reinforcing POM with glass fibers, the glass fibers tend to cause wear in the other material when sliding. This makes it difficult to have strong mechanical properties at the same time as good sliding properties. However, with DURACON® POM short cellulose fiber reinforced grades, the cellulose fibers cause little wear in the other materials (carbon steel, S45C). This makes it possible to have high rigidity along with superior sliding properties.

Future Outlook

In developing DURACON® POM short cellulose fiber reinforced grades, Polyplastics seeks to further reduce environmental impact through the application of DURACON® bG-POM*2 and usage of PCR*3 materials collected from the market. Additionally, it will be working on the material design to find a way to achieve the high strength that was not possible with conventional short cellulose fiber reinforced grades.

*1 Extracted as continuous fibers by putting natural cellulose through a wet spinning process (regenerated cellulose fibers).

*2 ISCC Plus-certified (International Sustainability & Carbon Certification) mass balance approach biomass allocated POM which we manufacture and sell.

*3 Post-consumer recycled. Refers to collecting used products from the market and recycling them

-28 October 2024-