ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Capacitor Boosts Immersion Cooling of Servers

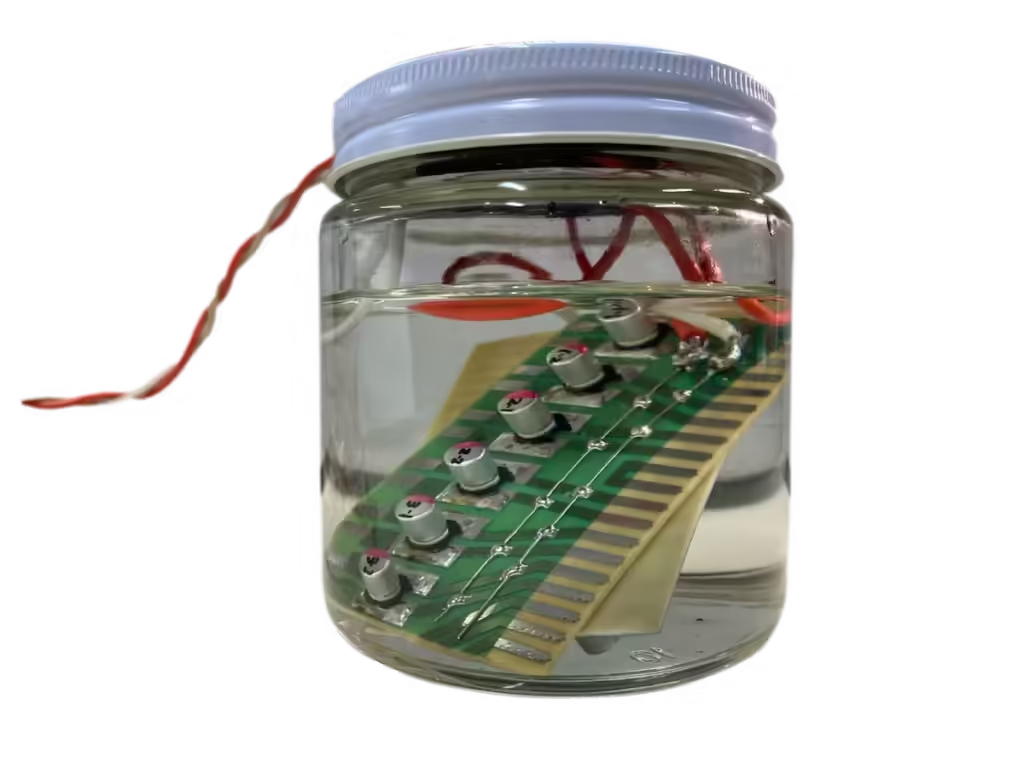

To contribute to the high performance of the expanding IT infrastructure, Nippon Chemi-Con Corp. has been promoting the enhancement of the functionality of aluminum electrolytic capacitors used in servers. Thus, the company announces the development of the industry’s first product that supports Liquid Immersion Cooling, a highly efficient server cooling method. It has also started handling samples.

In recent years, against the backdrop of the spread of generative AI technology, expectations are rising for the expansion of next-generation data centers. This trend is also supported by the promotion of digital transformation in the manufacturing industry and the use of automobiles as autonomous driving infrastructure.

On the other hand, AI servers in the market consume orders of magnitude more power than conventional server units due to the high performance of CPUs and GPUs. Additionally, the increase in heat generated by each server unit has led to a rapid increase in demand for cooling and air conditioning power in data centers. Accordingly, this results in an increase in power consumption of the entire data center. The energy consumption of data centers is on the rise. Also, it has become a global environmental issue as carbon neutrality efforts are underway in various countries.

The maximum power consumption of server racks in cloud data centers is about 10kW. Meanwhile, the air-cooled system is the mainstream. However, server racks for High-Performance Computing, such as AI servers are more than 20kW and in some cases more than 100kW. Therefore, cold plate or immersion cooling is indispensable as a cooling method. But there is a limit to the improvement of Power Usage Effective(PUE*1) with cold plate. It is expected that it will eventually be necessary to shift to more ideal immersion cooling.

On the other hand, immersing a general aluminum electrolytic capacitor accelerates the deterioration of the sealing rubber and shortens its life due to poor airtightness. Aluminum electrolytic capacitors are used in a wide range of applications in servers, from primary smoothing to CPU and GPU drives in the last stage. Also, they need to be able to cope with liquid immersion.

*1 PUE = (Power consumption of the entire data center [kWh]) / (Power consumption of IT equipment [kWh]). The PUE of a typical data center is about 2.0.

Taking advantage of Nippon Chemi-Con’s in-house development of sealing rubber, it has evaluated the airtightness resistance to immersion cooling and developed a new sealing rubber (patent pending). In addition, it continues to evaluate with the cooperation of major refrigerant manufacturers.

It has already received evaluations for immersion cooling from some users related to data centers. However, it assumes that cooling is a major issue in the automotive and industrial machinery markets.

This article is an online translation of a Japanese press release with minor editing made by Dempa.

-05 November 2024-