ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Process Integrates Analog, Digital to Single Chip

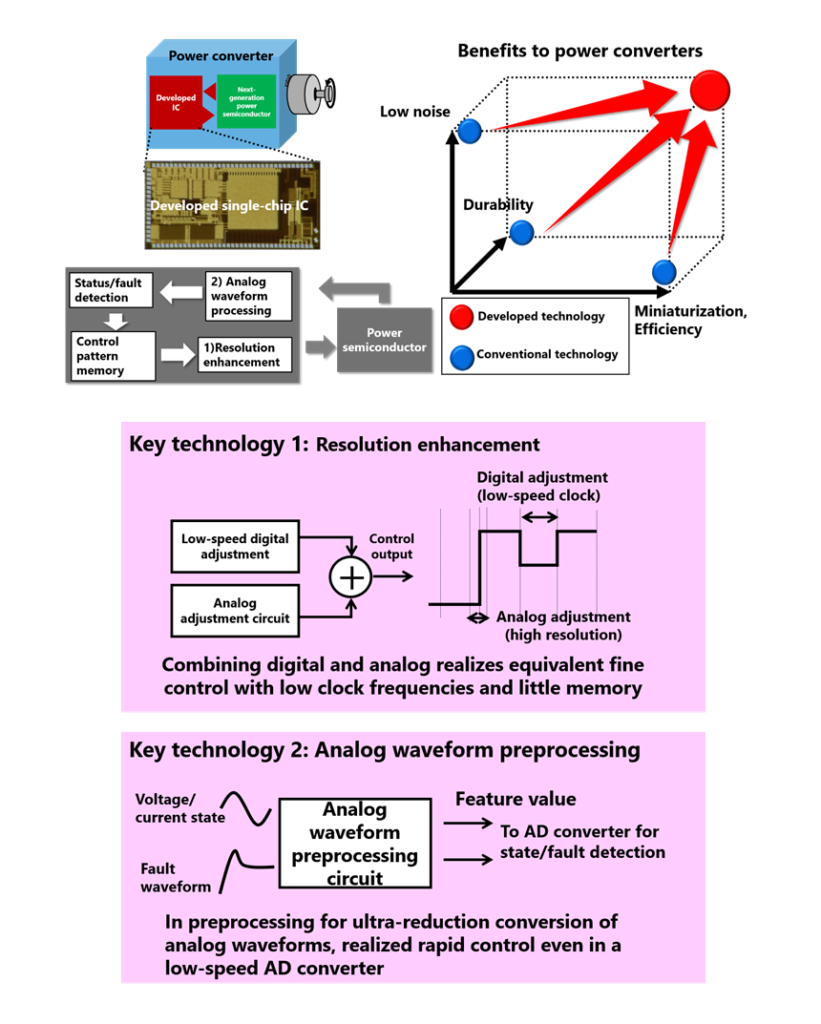

Toshiba Corporation has demonstrated a fabrication of high-performance circuits with analog–digital integration on a single chip driver IC. The company said the integration process, which is for controlling power semiconductors, is one of the first in the industry (1).

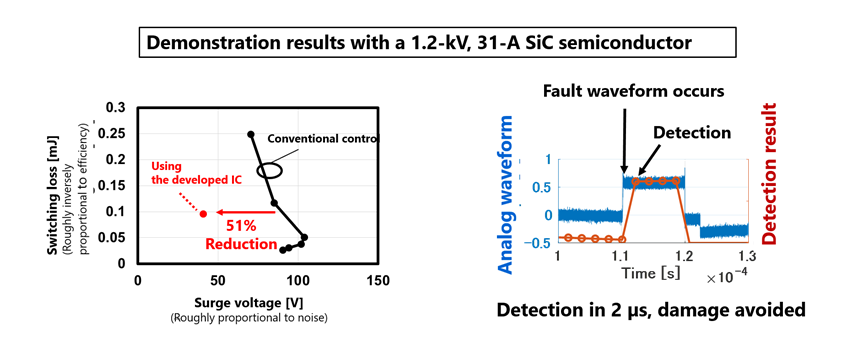

The developed IC detects the voltage and current status of power semiconductors at ultra-high speeds of 2µsec or less. In addition, the fine control reduces noise generated by power semiconductors by up to 51 percent.

Theoretical calculations also confirm reduction of power loss when driving the motor by 25 percent compared with equivalent noise reduction using conventional methods. In the event of a short circuit or other malfunction, it can protect the power semiconductor to prevent damage to it.

The technology maximizes the performance of next-generation power semiconductors. Thus, it will contribute to the realization of a carbon-neutral society. It will also aid in miniaturization, high efficiency, and high reliability of the motor drive circuits. Furthermore, it will also improve DC–AC converters used in electric vehicles, industrial equipment, smart power grids, and so on.

Development Background

Power semiconductors control voltages and currents. They drive motors in many applications and for DC–AC power conversion. To realize a carbon-neutral society, it is important to improve the efficiency and reduce the size of power semiconductors and power converters. Furthermore, the power semiconductor market continues to expand every year. Recent studies showed global market for driver ICs for controlling power semiconductors has grown from ¥140 billion (US$1.20 billion) in 2017 to ¥180 billion (US$1.57 billion) in 2021. Analysts think this trend will continue in the future (*2).

Currently, insulated gate bipolar transistors (IGBT) (*3) and silicon metal–oxide–semiconductor field-effect transistors (Si-MOSFET) (*4) are for power semiconductors applications. Further improving efficiency will require reducing the power loss that occurs during power conversion, so the development of next-generation power semiconductors with low loss characteristics such as silicon carbide MOSFET (SiC-MOSFET) (*5) is progressing.

Next-generation power semiconductors will reduce power loss in power conversion, achieve high efficiency, and facilitate heat dissipation. Correspondingly, this will enable reductions in both size and weight.

However, controlling these devices using conventional circuit methods will lead to power loss reductions but at the expense of increased noise. Furthermore, heat dissipation paths shrink, so in the unlikely event of a short circuit or other fault, the temperature will instantly rise, making it easier for semiconductor elements to break.

Research to reduce noise in next-generation power semiconductors by improving control methods results only to more issues because it differs to the voltage and current state of the power IC element. In addition, conventional methods require system designers to implement fault detection and protection functions for short circuits via microcomputer. The inherent delay can result in damage to the element.

Features of the Technology

Toshiba addressed this problem by developing the high-performance single-chip gate driver IC with mixed analog and digital circuits. Conventionally, realizing high functionality like that provided by this IC required configurations using many individual semiconductor components such as signal converters, memories, operation circuits, and amplifier circuits.

However, mounting analog and digital circuits together requires using analog circuit to detect voltage and current in power semiconductor elements. It will also need digital circuit to select a control method based on the detection results. Accordingly, this will realize optimum control by a single chip without many parts.

The developed semiconductor also has memory for storing control methods, and during control, a resolution enhancement circuit combining low-speed digital and high-speed analog circuits realizes appropriately fine control by using analog circuits only for those parts requiring high-speed control.

Toshiba has also developed an analog waveform preprocessing technology that extracts only those features required for control and fault detection from the high-speed voltage and current waveforms of power semiconductors, allowing fault detection with a low-speed analog-to-digital converter. Thus, there is no need to pass through a microcomputer, allowing immediate detection of short circuits and other faults.

Low-cost complementary metal-oxide-semiconductor (CMOS) (*6) process technologies that are compatible with existing fabrication equipment can also realize this IC. Using this IC, the company succeeded by 51 percent in controlling a 1.2kV SiC-MOSFET power semiconductor and reducing its surge voltage, which is a major cause of noise generation, with no increase in power loss.

Using conventional methods for an equivalent surge reduction would increase loss when driving the motor. However, theoretical calculations clearly show that using this IC can reduce power loss by 25 percent. The IC also succeeded in fault state detection at speeds as low as 2µsec without using a microcomputer. These features can maximize the performance of next-generation power semiconductors.

Future Developments

The Toshiba Group will aim for practical use of the developed IC by 2025. Power electronics is a market of focus for the Toshiba Group, which will continue to develop technologies related to this IC. The group will promote the application of next-generation power semiconductors to various power conversion systems. Undoubtedly, contributing to the reduction of CO2 emissions through higher efficiency of power semiconductors and realize a carbon-neutral society.