ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi Electric to Ship Samples of High-Power IGBT Module

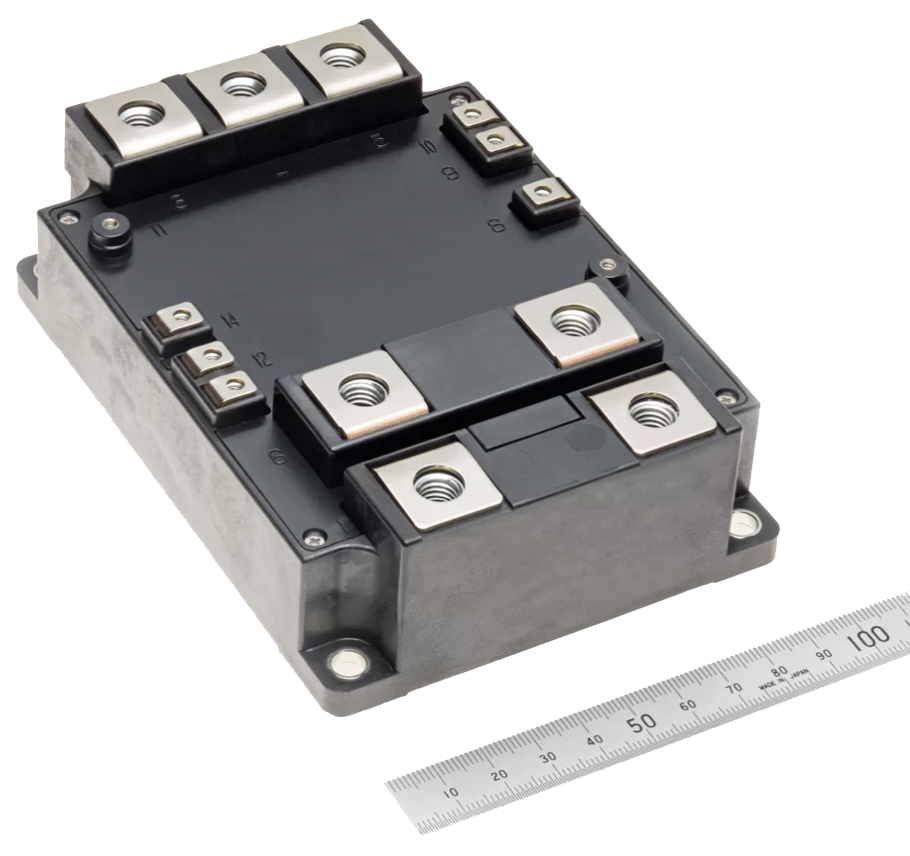

This May, Mitsubishi Electric Corporation will ship samples of its LV100-type T-series 2.0kV insulated-gate bipolar transistor (IGBT) module for industrial use. The power-semiconductor product will downsize and reduce the power consumption of power-conversion equipment for renewable-energy sources.

Promotes Carbon Neutrality

Power semiconductors efficiently convert electric power. They are increasingly utilized as key devices that help lower the carbon footprint. Also, power grids that use renewable-energy power sources demand efficient power conversion. This can be achieved through the deployment of increasingly higher system-operating voltages. Eventually, this process has led to the development of power converters rated at DC 1500V, the upper limit of the EU’s Low Voltage Directive.1

Reduce Power Consumption

The module samples have a blocking-voltage capability of 2.0kV, which is suitable for DC 1500V power conversion equipment. These are used mainly for large-capacity systems of several hundred kilowatt to several megawatt, including renewable-energy power sources. Adopting 2.0kV withstand voltage semiconductors will enable customers to simplify the design of their DC 1500V power-conversion equipment.

Also, the latest 7th-generation IGBT and Relaxed Field of Cathode (RFC) diode2 will help downsize and reduce the power consumption of power-conversion equipment for renewable-energy power supply. In addition, the module’s industrial LV100-type package, which is suitable for large-capacity systems due to its easy-paralleling configuration, will help simplify large-capacity system designs.

Product Features

Downsize DC1500V power converters

The new 2.0kV-rated IGBT simplifies the design of DC 1500V-rated power converters. It also targets renewable-energy power sources, which are difficult to design using conventional 1.7kV-rated IGBTs.

Reduce power loss in power converters

The latest (7th gen) IGBT with CSTBTTM3 structure and RFC diode optimized for high withstand voltage are suitable for high-voltage, lower-power-loss applications.

Increase capacity of power-conversion systems

The terminal layout is optimized for easy paralleling and flexible inverter configurations and capacities.

There are three AC main terminals that help spread and equalize current density for increased inverter capacity.

Moreover, integrating the structure’s insulated and copper-base parts and optimizing the internal electrode structure increase thermal cycle life. They also lower package inductance for enhanced reliability.

Next Step

The new IGBT Module is scheduled for mass production in December 2022. After which, its introduction will support the adoption of DC 1500V power-conversion equipment for renewable-energy power sources. These include power-generation systems and power-storage systems; thereby contributing to the eventual realization of a carbon-free world.

Reference:

1The directive provides common broad objectives for safety regulations, so that electrical equipment approved by any EU member country can be acceptable for use in any other EU country.

2Mitsubishi Electric’s original diode that optimizes electron mobility on the cathode side

3Mitsubishi Electric’s original IGBT structure using the carrier-storage effect