ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

IMTS 2022 Showcases Cutting-Edge Manufacturing Tools

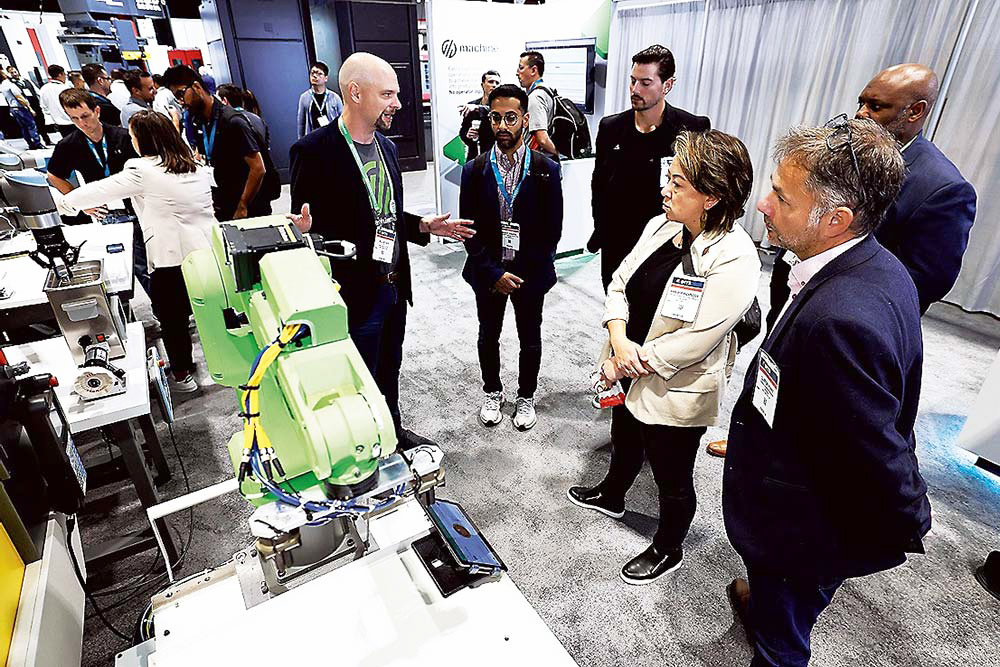

The International Manufacturing Technology Show (IMTS) 2022, the largest manufacturing technology fair in North America, had its successful run at Chicago’s McCormick Place from Sept. 12 to 17. About 2,000 companies participated in IMTS with about 86,000 visitors in total during the six-day event. The Association for Manufacturing Technology (AMT) organized the said event.

IMTS is one of the world’s four major trade fairs on machine tools, along with Japan International Machine Tool Fair (JIMTOF), EMO Show in Hanover, Germany and Milan, Italy, and China International Machine Tool (CIMT) in Beijing, China. IMTS is usually held every two years, but due to the COVID-19 pandemic, it was cancelled in 2020.

Expanded Range of Manufacturing Tools

The prominent manufacturing show targets an expanded range of manufacturing equipment. Among them include machine tools, industrial robots, 3D printers, and numerically controlled (NC) machines. Additionally, it features forge rolling machines, machine tools, gear devices, hydraulic/pneumatic/water pressure equipment, precision measuring equipment, optical measuring equipment, testing equipment, CAD/CAM, among others.

Notably, nine technology pavilions were set up at the event site. They cover multi-tasking machining centers, robots, digital twins, manufacturing software, controls, 3D printers, and quality control/inspection.

Mainly, exhibitors presented cutting-edge innovations in the manufacturing industry, including artificial intelligence (AI), digital twin, data analysis, cyber security, cloud computing, process monitoring, and predictive maintenance. Specifically, FUJI Corporation, NSK Ltd., Mitsubishi Electric Corporation, and FANUC Corporation led major Japanese machine tool manufacturers that participated in the exhibition.

Japanese Technologies on Display

FUJI Corporation introduced the GYROFLEX multi-tasking machine; DLFn modular production equipment; CS Series front facing twin-spindle lathe; TN II Series horizontal NC lathe; and ANW Series opposed twin-spindle lathe.

GYROFLEX enables various machining with up to 70 types of cutting tools on the tool spindle together with turret-type tool posts. It is suitable for high-mix, medium-volume production through process integration. It promotes space saving as it can complete machining process in a single machine.

In DLFn, advanced technology for electronic component mounting robots is incorporated into the machine tools. Various machine and equipment modules are mounted on a standardized platform. As a result, a miniature factory is realized as a production line can be considered a small factory.

Nowadays, integrated automation solutions are being rapidly developed to improve accuracy and higher throughput of machine tools. At IMTS, NSK Corporation exhibited products and technologies that realize optimal and efficient production processes. Mainly, the ROBUSTDYNA spindle precision bearing and the AXIS Series mono-carrier actuator led the list of these products. Specifically, these tools attain advanced machining capabilities and enable innovation in production lines.