ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

LG Innotek Touts New High-Performance 2Metal COF

LG Innotek had introduced 2Metal Chip on Film (COF), an essential product for extended reality (XR) devices, to strengthen its captured markets. The product attracted visitors’ attention at LG Innotek’s metaverse zone at its booth in CES 2023.

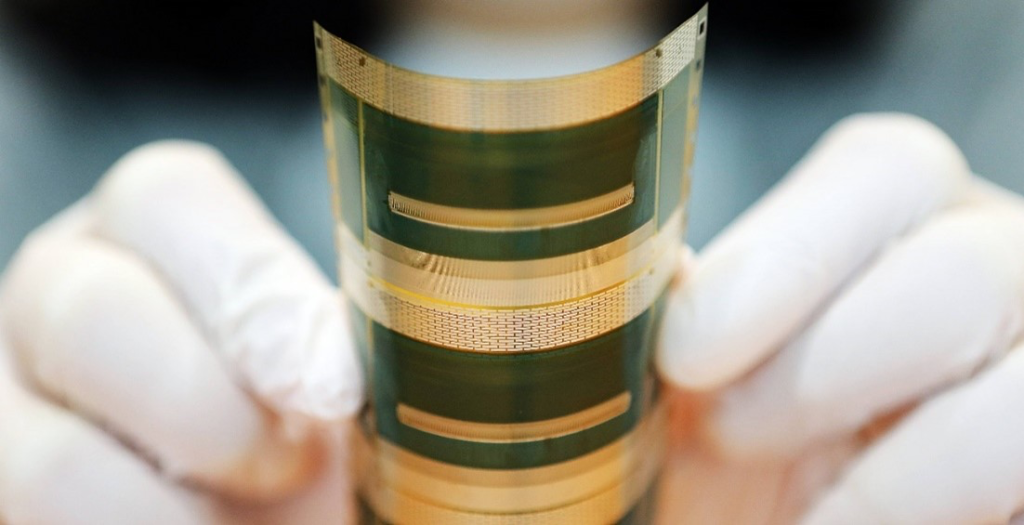

COF is a semiconductor package substrate that connects displays and flexible printed circuit boards (FPCBs). It minimizes display bezels of devices such as TVs, notebook PCs, monitors, and smartphones, reducing the modules’ form factor. Also, it requires advanced technology because it forms microcircuits on a very thin film. COF is also called ultra-thin flexible PCB.

Upgrade from Traditional Single-Side COF

2Metal COF technically upgrades the conventional single-side COF. A conventional COF implements circuits on only one side. Meanwhile, 2Metal COF is super integrated by forming circuits on both sides, which is its biggest advantage.

This product finely perforates micro-via holes on a thin film and implements an ultra-micro circuit on both sides. Then, it transmits signals between electronic devices more quickly and enables ultra-high definition display.

According to LG Innotek, this product’s via hole measures 25μm relative to 100μm hair thickness. The smaller via holes create more channels connecting the product’s top and bottom. It also allows more pattern circuits that electrical signals can pass through.

Recently, as the metaverse era has been in full swing, curved or folding displays are increasingly demanded. Moreover, attached components also requires flexibility. This is also the reason why 2Metal COF, which is bent freely, is considered one of the products in line with current trends in the display industry.

Supports High-resolution Display

LG Innotek’s 2Metal COF forms more than 4,000 circuits on a film. Specifically, in pattern circuits, or channels, a signal passes per display pixel. Generally, more pattern circuits result in enhanced pixels. XR devices require higher levels of immersion that only enhanced pixels can deliver.

If the resolution of the virtual image displayed through an XR device is low, users may feel like viewing the image through a mosquito net, or the screen door effect. Since 2016, LG Innotek has continuously improved the specifications of the 2Metal COF to minimize the screen door effect and support ultra-high resolution.

In particular, LG Innotek applied new engineering technology to reduce the circuit width from 18 to 16μm pitch, representing the narrowest level in the industry. Since the number of pattern circuits that can fit on the COF surface increases as the circuit width is reduced, users can view images with better quality, even on a display of the same size.

IT manufacturers are increasingly adopting displays with high definition and minimal bezels to enhance the competitiveness of their devices. In the past, manufacturers used chip-on-glass (COG) technology to support display operations. However, as COG places a chip on a display, it does not meet current display industry trends of no bezel and flexible since it cannot support flexibility. It forced the manufacturers to look for alternative technology that stably supports high pixels while the display’s bezels is reduced, leading to wide demand for 2Metal COF.

Flexibility and Unbounded Design with Thin Films

LG Innotek’s 2Metal COF is a thin, flexible film type that can be smoothly folded or rolled. Moreover, it bends more smoothly than conventional single-sided COF. It reduces the required mounting space for the display, and set makers can secure more space for other parts. It even helps with designing and engineering more advanced XR devices.

LG Innotek applied unique ultra-micro circuit forming technology to double the circuit integration of the 2Metal COF while minimizing the thickness. The product’s film thickness is only 70μm, the thinnest of semiconductor substrates. It clearly offers many advantages compared to the thickness of 150μm or more for conventional semiconductor packaging substrates.

Reducing the thickness helps make finished products more flexible and slimmer. It increases design and engineering freedom for display panel manufacturers. Also, consumers find products with designs that are more complete than conventional XR devices.

Opening the Era of XR

LG Innotek is further advances its technologies and actively carries out promotional activities in North America and Japan, where many XR device companies are active, to widen the lead from competitors.

The highly integrated circuit implementation technology of 2Metal COF is applied as an alternative technology for products, in which FPCBs are not satisfactory and are developed for new product group applications such as micro LEDs.

“We will continue to lead the 2Metal COF market based on the technical capabilities and quality that have led the substrate business for 50 years,” said Son Kil-dong, Senior Vice President of the Substrate & Materials Business. “We will continue to create differentiated customer value with products that can be applied to various applications.”