ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

New Roll Core Material Reinforces Substrate Production

Sumitomo Bakelite Co., Ltd. has commenced mass production of roll-type core material that accommodates reel-to-reel continuous substrate production at its facility in Utsunomiya, Japan.

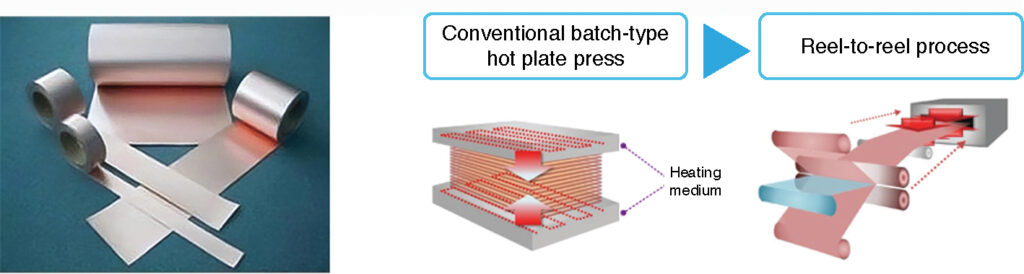

Sumitomo Bakelite has produced and sold the LaZ Series semiconductor package substrate material that features low thermal expansion, high rigidity, and high elastic modules. In general, setting copper foils on both surfaces of the prepreg, which is press-molded and cured using the sheet feed method, produce the core materials.

Meanwhile, thinner substrates for devices and higher integration of devices require reduced substrate thicknesses. The thicknesses of core materials are also becoming smaller. As they become thinner, the more difficult substrate manufacturers find them to handle, thus decreasing yield.

In addition, there are limited number of manufacturers that can handle thinner core materials, raising concerns on supply availability of low-cost materials.

Offers Superior Quality Stability

Sumitomo Bakelite can manufacture roll-type core materials using the innovative continuous production method. In the reel-to-reel roll-type core material continuous substrate production method, continuous production of substrate does not require manpower. This is because the transfer of core materials during the production process is by the rolls. Manufacturers widely adopt this kind of production method in producing flexible circuit boards.

This method reduces handling loss and enables continuous production of different substrates. Theoretically, material loss occurs only at both ends of the material and high area yield is still possible. A substrate manufacturer has already adopted for the first time Sumitomo Bakelite’s roll-type core material for ultrathin double-sided two-layered substrates.

This method has excellent quality stability, including thickness, physical property, and dimensions, and holds great potential to solve various problems in the production of ultrathin substrates in the future. As it can provide core materials thinner than 20μm, the production of which using conventional press production method is difficult. It will however meet future requirement for further thickness reduction. It will also enable the provision of ultrathin rigid substrates using the production method with cost competitiveness.

Sumitomo Bakelite aims to expand the market of the roll core materials targeting ultrathin two-layered substrates that are used in devices for which major growth is expected in the future, such as the display market and memory market.