ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

LG Innotek Develops High-Performance Magnet for Car Motors & Camera Actuators

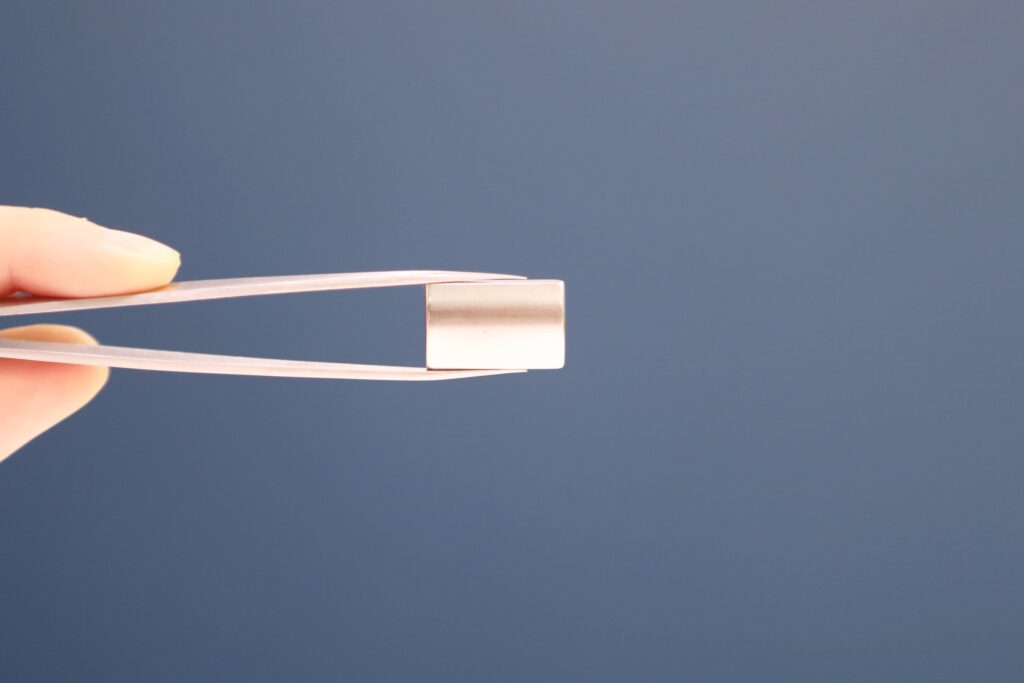

LG Innotek has developed an eco-magnet in collaboration with Sunglim Group of Korea in what the company said is the world’s strongest in terms of magnetic force.

The development will open up the way for the Korean electronics parts and components maker to challenge the leadership of China and Japan in global magnet market

The magnet is an essential component for vehicle motors and actuators for smartphone cameras and audio speakers, as well as wind power generators, generating power with its magnetic pushing and pulling force.

Yet, heavy rare-earth, or HRE metal, a key raw material for the magnet, is so scarce that the supply always stays unstable. Prices are volatile, too,

On the other hand, demand for the magnet is soaring, mainly due to the rapid penetration of EVs, or electric vehicles.

To tackle the imbalance, magnet makers like LG Innotek have been struggling to find the way to use less of the HRE without compromising magnetic force, but to no available.

LG Innotek has eventually blazed the trail, coming up with the eco-magnet that maintains strong magnetic performance even if it is made of less amount of HRE.

According to LG, this eco-magnet contains 60% less HREs that conventional products, but can generate stronger magnetic force than other competing magnets of the same size.

For example, this magnet boasts of the magnetic performance 14.8 kG (in kilogauss, magnet strength), which is the world’s highest level, when it us used with home appliances and vehicle steering motors.

This beats the products of Japanese companies that have led the industry for nearly 40 years.

The industry believes that the technical performance limit of this magnet is 15kG. The magnetic performance of products commercialized so far is only 14.2 to 14.3 kG.

This can increase the driving power of an actuator by about 10% without an increase in size. Therefore, even if a lens becomes heavier, the actuator can move the lens as quickly and accurately as needed when it is used in a smartphone camera.

It can also result in clear high-definition photos by improving the driving power of smartphone cameras by about 10%.

Contains Less of HRE, But Comes Stronger

As the specifications of smartphone cameras have sophisticated, the size and weight of lenses have increased.

And this now requires actuators to have stronger magnetic power. At the same time, as smartphones get slimmer, there are strong requirements for small but powerful magnets.

When it comes to a steering motor of a vehicle, the magnet is advantageous, too, as it can help reduce the weight of the vehicle.

The magnet reduces the size of the motor while increasing its output; the high magnetic power enables high motor output with a small size.

This product is suitable for electric and hybrid vehicles that need weight reduction to improve mileage range (fuel economy of electric vehicles) due to an increase in battery weight.

This magnet can also cut the cost of raw materials such as copper used in motors as it decreases the motor size.

Until now, Japan and China have dominated the global magnet market, as Japan has a cutting-edge technology, while China has an abundant supply of HRE metals.

Catch Up

To beat out the two forerunners, LG Innotek began developing the eco magnet with reduced HRE metals in 2017 and has been focusing on securing the best magnetic performance since 2019.

To this end, LG Innotek also joined hands with SGI, which has an HRE metal reduction technology.

HRE metals are an essential component to maintain magnetic force at high temperatures. Reducing these metals may decrease the durability of a magnet. Therefore, it was technically difficult to enhance the magnetic force while minimizing the use of HRE metals.

By adding new compounds, the two companies have developed a coating liquid for the eco magnet that uses less HRE metals, but produces the strongest magnetic force in various products and temperatures.

In addition, the companies have also secured a new magnet material optimized for the coating liquid.

LG Innotek’s eco magnet is made by applying this coating liquid to the magnet and heating the magnet to absorb the liquid evenly.

AI, or machine learning algorithm was instrumental in this R&D process, allowing a computer to automatically simulate the process and determine optimal conditions such as the ratio of HRE metals and heat treatment temperature. It helps to halve the development time which usually takes 2 years.

Previously, researchers had to repeat experiments hundreds of times, which made the development period long and incurred errors.