ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Robotics Boosts Grit With More Reliable Lineup

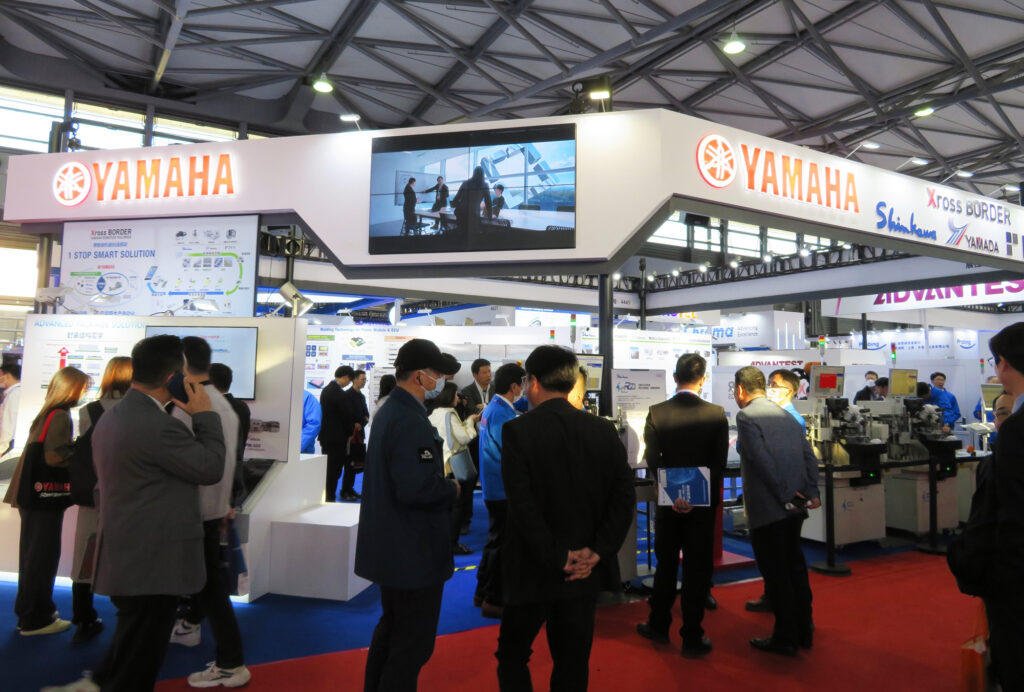

Yamaha Robotics Holdings Co., Ltd. exhibited a variety of manufacturing equipment for back-end processes at the recent SEMICON China 2024.

Specifically, the company aims to expand its business in the Chinese market by leveraging its strength in providing more equipment. Thus, recognizing the importance of back-end processes amid 3D stacking and the use of different types of bonding.

1 STOPT SMART SOLUTION

Yamaha Robotics Holdings started in July 2019 through the business integration of Shinkawa Ltd, APIC YAMADA Corporation, and PFA Corporation. Thereafter, it became a wholly owned subsidiary of Yamaha Motor and changed its name to the current name in January 2021.

The addition of YAMAHA Motor’s surface mount equipment to Shinkawa’s bonding equipment, APIC YAMADA’s molding equipment, and PFA’s active alignment equipment created synergies. Thus, providing “1 STOP SMART SOLUTION” from semiconductor back-end processes to electronic component mounting.

At SEMICON China, Shinkawa’s UTC-5000 NeoCu Super high-speed Cu wire bonder attracted much attention. Specifically, the combination of an automatic transfer device and robot take spotlight in an automated line. Moreover, the company exhibited as reference product its next-generation compact UTC-RZ1.

Other Products on Display

Ryosuke Nakamura, President & Representative Director, Yamaha Robotics Holdings Co., Ltd. commented, “We cover three areas of semiconductors: (1) advanced, (2) power, and (3) legacy. In the Chinese market, we are increasing sales mainly of power and legacy semiconductors.”

Also on display were APIC YAMADA’s WCM-330 auto molding system for WLP and PFA’s A300-SUPER active alignment system for camera module manufacturing. Particularly, the A300-SUPER complements manufacturing camera modules for smartphones. Nonetheless, the company will expand its application to automotive cameras in the future.

Nakamura said, “Our strength is ‘1 STOP SMART SOLUTION. By grasping customer needs for each piece of equipment and responding quickly, we can increase the value of our overall solutions. We will also respond to the increasing demand for automation in the Chinese market, which will lead to business expansion.”

-16 April 2024-

*This is an English translation of a Japanese article originally published in the April 12, 2024 issue of Dempa Shimbun Daily.