ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Nachi Fujikoshi New Injection Molding Tool Fits Fluororesins

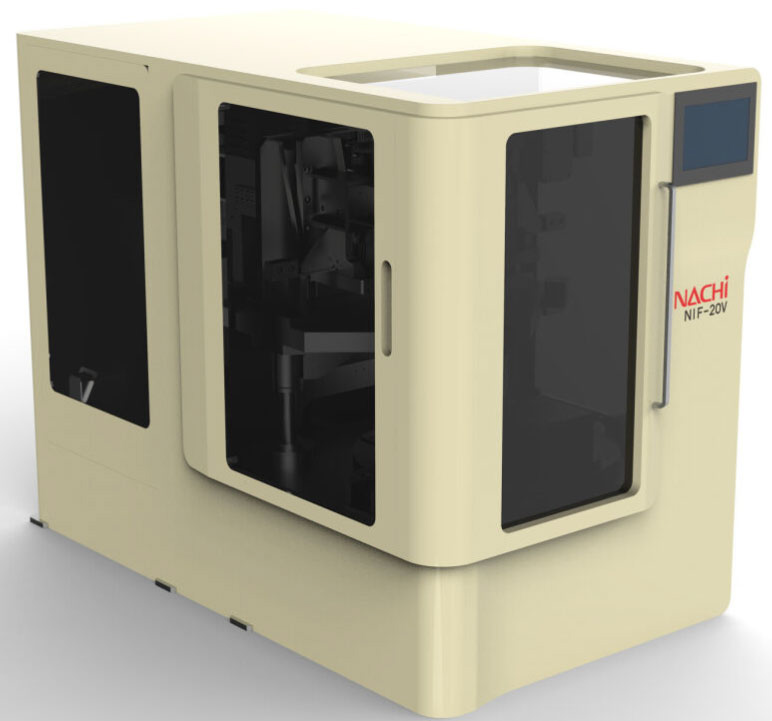

Nachi Fujikoshi Corp. has released NIF-20V, a compact injection molding machine for fluororesins.

Injection molding machines are often used for manufacturing parts using thermoplastic resins as one of plastic molding processing methods. In recent years, there has been an increasing demand for fluororesins highlighting non-stick, wear resistance, heat resistance, chemical resistance, and corrosion resistance features. Particularly, this trend is notable in semiconductor manufacturing equipment, transportation equipment and electrical components.

On the other hand, in the fluororesin molding process, contamination is likely to occur. Primarily, this is due to wear, deformation, and corrosion of injection molding equipment parts. Thus, many are forced to make inefficient production with large equipment with horizontal specifications. This happens because of the unavailability of a dedicated equipment suitable for small-molded products.

In Feb. 2024, Nachi Fujikoshi developed and launched NIF-20V suitable for insert molding of small products. Specifically, it is a vertical-type injection molding machine that reduces contamination and thermal deterioration and resin materials in fluororesin molding process. Mainly, the company utilized its technical strengths in materials, hydraulic pressure, and machine tools, cultivated as a comprehensive machine maker.

With the new machine, the company targets the semiconductor field. Particularly, it eyes components for semiconductor manufacturing equipment, like valves for chemical liquids, fittings, sensor covers, pumps. Meanwhile, in the transportation equipment, it targets automobile and electrical parts, like sealing materials, sensor covers.

Features of NIF-20V Injection Molding Machine

(1) High Quality: Realizes high-quality fluororesin molding. Particularly, it reduces contamination caused by wear and corrosion of injection molding machine components, shortens resin retention time per cycle and suppresses thermal deterioration of resin materials.

(2) Durability: It features dramatic improvement in durability by using corrosion-resistant, high-hardness alloyed NPR-FX25 developed in-house as material for fluororesin injection units.

(3) High Precision: Precision hydraulic servo system helps powerful and highly accurate control of injection and mold clamping operations.

(4) Productivity: Vertical-type specifications suitable for insert molding, and a variety of molded products and small lots available (Therefore it is possible to downsize the equipment and dies)

(5) Maintainability: Torpedo plunger system adopted for easy injection unit replacement

-22 April 2024-