ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Dell Makes Big Move to Drive Edge in Manufacturing

Dell Technologies is expanding its edge partner ecosystem with Hyundai AutoEver and Intel. Specifically, to help manufacturers derive more value from their edge data with AI.

Moreover, these collaborations highlight a pivotal role played by the Dell edge ecosystem in customers to harness the power of their edge data.

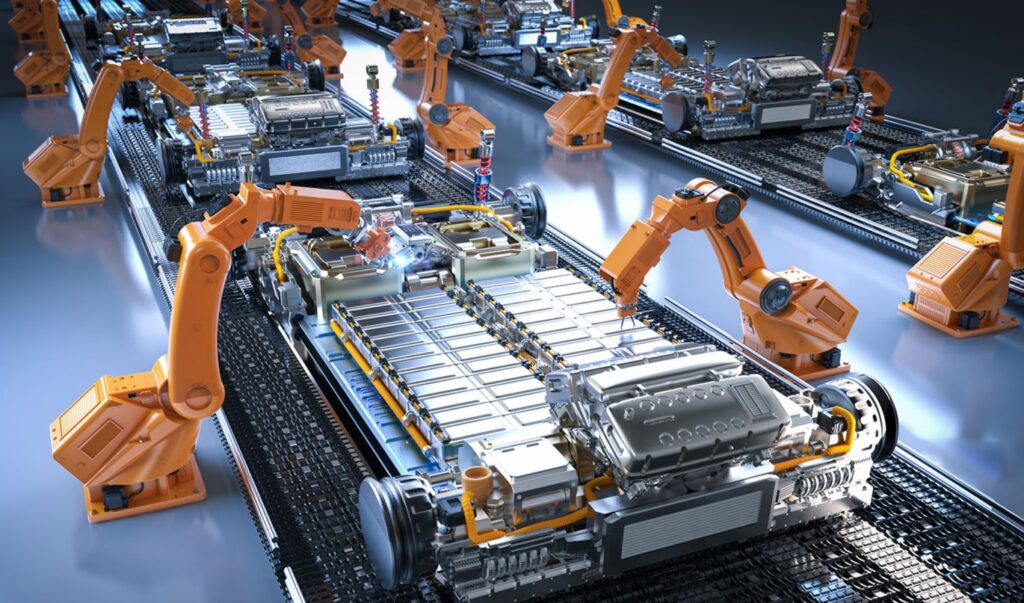

Imagine you’re a plant manager of a factory. Think of all the points in the factory that generate data. Particularly, machinery status and part production, cameras on the assembly line monitoring processes, and safety, packaging and logistics. Add to this the overall factory performance and ensuring the security of both IT and OT equipment in the building. Manufacturers can analyze this vast amount of data created at the edge in real-time to make critical decisions and drive better business outcomes.

Artificial intelligence (AI) will likely transform how quickly and accurately to collect, analyze, and act upon edge data. Therefore, IDC expects AI will drive major growth in edge computing spend over the coming years, with worldwide edge computing spend expected to reach $232 billion in 2024, an increase of 15.4% over 2023.¹

Dell and Hyundai AutoEver Edge AI Technologies Enhance Factory Processes

To ease transition to an AI-enhanced factory, Dell is introducing updates to the Dell Validated Design for Manufacturing Edge with that of Hyundai AutoEver.

Hyundai AutoEver, a subsidiary of Hyundai, offers smart factory solutions that integrate with existing IT and OT infrastructure. Thus, providing simplified operations and digital continuity for manufacturers.

By integrating the Dell Validated Design for Manufacturing Edge with Hyundai AutoEver’s NeoFactory IoT software, manufacturers can facilitate AI-driven optimizations and outcomes for their factory processes. How does this impact plant managers? They can quickly monitor equipment performance, detect anomalies and use predictive maintenance to reduce downtime, increase productivity and eliminate costly process waste.

In addition, the Dell Validated Design for Manufacturing Edge has the support of Dell’s NativeEdge. Manufacturers can simplify infrastructure deployments, manage multiple applications on the factory floor. Furthermore, it can scale infrastructure and applications quickly, while maintaining factory security.

“In collaboration with Dell Technologies, Hyundai AutoEver’s NeoFactory IoT elevates modern manufacturing by using real-time data and AI at the edge to inform decisions and drive business growth. Our integration with Dell NativeEdge ensures scalable, secure solutions that set a new benchmark for manufacturing excellence and digital transformation. Together, we will deliver key outcomes tailored to meet diverse customer needs, redefining the future of industrial connectivity.”

More AI-Driven Capabilities and Choice with Expanded Partner Ecosystem

Meanwhile, the Dell Validated Design for Manufacturing Edge supports a diverse ecosystem of partners and independent software vendors (ISVs). Particularly, offering manufacturers a broad choice and flexibility in how they manage the data on their factory floors. Dell has wide ecosystem partners that continue to innovate and deliver technologies to manufacturers. These include the digital twin capabilities of XMPro and advanced quality control with AI-enabled smart cameras from Cognex. Moreover, the enhanced on-prem threat detection from Claroty.

NativeEdge Blueprints for Intel Edge AI Services

In addition, Dell is also introducing enhancements to Dell NativeEdge Blueprints using Intel’s OpenVINO Developer Toolbox. Particularly, the integration provides businesses with more flexibility for the deployment and management of AI and machine learning applications at the edge.

Simplified orchestration and management of edge computing resources provide seamless and secure application deployment on Intel-based hardware. Thus, optimized AI inferencing offers real-time insights and improved operational efficiency for businesses.

-24 April 2024-