ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

IBM to Adopt New Wet Processing System by Veeco

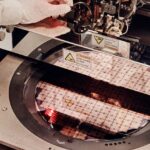

Veeco Instruments Inc. has announced that IBM selected its WaferStorm® Wet Processing System for advanced packaging applications. In relation, it has entered into a joint development agreement with Veeco. Specifically, it will explore advanced packaging applications using Veeco’s multiple wet processing technologies.

Under the agreement, the Waferstorm Wet Processing System will be installed in the Albany NanoTech Complex in Albany, NY. This is where IBM and other ecosystem partners are driving leading-edge R&D in advanced packaging and chiplet technologies.

Enables Hybrid Bonding Cleaning Process

Mainly, the WaferStorm system enables crucial hybrid bonding cleaning processes such as resist strip, temporary bonding strip. Also, it allows pre-bond cleaning with low defectivity thresholds at 40nm and 60nm. Moreover, the WaferStorm Wet Processing System’s ImmJET multi-wafer immersion and high-pressure spray technology can perform multiple processes on one flexible platform, which can handle multiple wafer sizes and thicknesses with minimal hardware modifications.

“The collaboration with IBM illustrates Veeco’s commitment to partnering with leading device manufacturers at the forefront of critical emerging technologies including cloud and AI innovation,” commented Mathew Abraham, Veeco’s Vice President of Wet Processing Products.

“Our innovative high throughput platform with industry-leading cost of ownership, powered by our proprietary ImmJET solvent technology, propels Advanced Packaging like never before and allows for superior process capabilities and cost-effectiveness. We’re keen to strengthen our relationship with IBM, a major tech pioneer pushing the limits of Advanced Packaging adoption.”

Due to its exceptional flexibility, Veeco’s WaferStorm system is the industry choice for critical wet processing applications in the advanced packaging, MEMS, RF, data storage, and photonics markets. Primarily, the system supports a wide range of processes, including metal lift-off, photoresist, flux clean, scrubber, and TSV cleaning. With its process performance record and low cost of ownership, the WaferStorm system helps to ensure optimal results for photoresist strip and dry film strip applications. Thus, it becomes the ideal choice for customers keen on innovation.

-16 August 2024-