ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

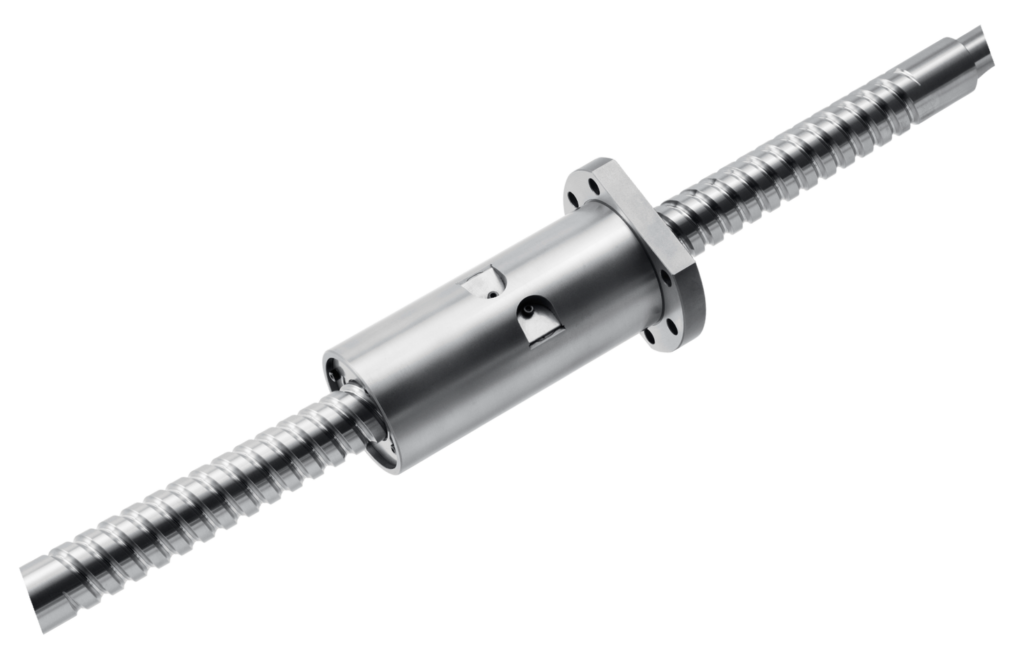

NSK Launches New Low-Friction Ball Screw

NSK Ltd. has developed the “MT-Frix™” *1low-friction ball screw. Particularly, NSK’s analysis technology accurately clarified the contact state between the balls and grooves inside the ball screw. Accordingly, it optimized the internal specifications and reduced dynamic friction torque*3 while maintaining the same dimensions and rigidity*2. As a result, the company has achieved a significant reduction in heat generation. Also, it kept the positioning accuracy of machine tools and reduced CO₂ emissions due to dynamic friction torque by up to 50% compared to conventional models.

This product will be exhibited at “JIMTOF2024 32nd Japan International Machine Tool Fair” to be held from Nov. 5 to 10, 2024. NSK plans to begin accepting orders in April 2025. It aims to achieve sales of 500 million yen in 2027 for this series.

Background

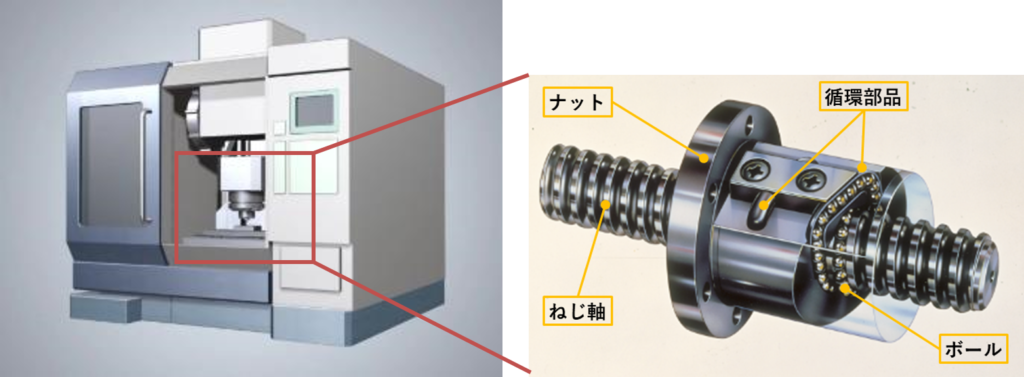

Ball screws are installed in the linear drive section of machine tools. Primarily, they are responsible for positioning processing tools and workpieces. In recent years, with the advancement of machining and decarbonization, there has been a growing need for ball screws to have higher precision positioning and that save energy.

When a ball screw is driven, it generates heat due to dynamic friction torque. Thus, it causes thermal expansion of the screw shaft, which reduces positioning accuracy. Meanwhile, forced cooling (cooling the generated heat using attached equipment, etc.) may be used to prevent precision degradation due to heat generation. However, it consumes extra energy due to the operation of the cooling equipment. Therefore, to achieve both high precision and energy savings, it is necessary to reduce the dynamic friction torque itself.

However, with conventional technology, when dynamic friction torque is reduced, the rigidity also decreases. This makes it easier for the nut to displace, resulting in a reduction in machining accuracy. Therefore, there is a need for technology that reduces dynamic friction torque while maintaining rigidity.

Technology of Developed Product

Using NSK’s analysis technology, the contact state between the ball and the groove was clarified. Accordingly, it developed the optimal internal specifications.

⇒Reducing dynamic friction torque while maintaining rigidity while keeping the dimensions of the ball screw the same.

Features of the Developed Product

Achieved reduction in dynamic friction torque and heat generation while maintaining the same dimensions.

1) Reduction of dynamic friction torque: Rigidity is the same as before, but dynamic friction torque is reduced by up to 50% compared to conventional models.

2) Reduced heat generation: By reducing dynamic friction torque, heat generation (temperature rise value) during ball screw drive is reduced by up to 40% compared to conventional models.

Effects on Machine Tools

1) Maintaining high positioning accuracy: By reducing heat generation, the amount of shaft elongation is reduced by up to 40% compared to conventional products, reducing the decline in positioning accuracy.

2) Energy saving: CO₂ emissions due to dynamic friction torque are reduced by up to 50% compared to conventional products.

*1 “MT-Frix™”: The origin of the word is MT (the initials of Machine Tools) + Frix (a coined word based on Friction). It means a ball screw with optimal friction properties for machine tool applications.’

*2 Rigidity: resistance to deformation due to external loads

*3 Dynamic friction torque: Torque due to friction generated when rotating a ball screw

This is an online translation of a Japanese press release with slight editing made by Dempa.

-07 October 2024-