ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

FUJI’s Unique Process Improves SMT Efficiency

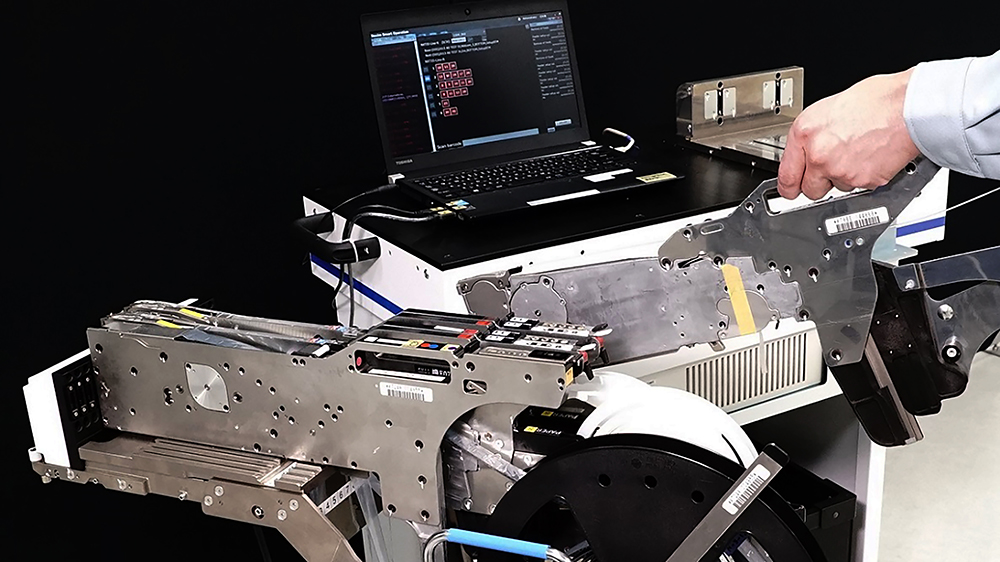

FUJI Corporation proposes Smart Setup Station, a support unit that improves efficiency of the offline changeover work in the surface mount technology (SMT) process. Here, the SMT in production sites of high-mix production, where models change frequently, face major issue. This is because production efficiency reduces with the increase in the number of times of changeover.

Moreover, many production sites adopt the batch exchange method where loading of feeders happens offline and replace feeder exchange units to reduce changeover time. However, offline changeover work involves many works that require checking out components to setting up feeders. In addition, they are delicate, and they do take time as well. The time needed for this task varies depending on workers and it is difficult to schedule the process.

Reduces Work Time

Understandably, Smart Setup Station links with the offline changeover function of the company’s Nexim integrated production system. Thus, this resolves the problem involving offline changeover work.

When starting an offline changeover work, the parts used in the previous production are still present on the feeder pallet or multi feeder unit (MFU). Therefore, it is necessary to remove the parts that are not necessary. In addition, manually removing unnecessary feeders of parts while looking at the changeover list requires a lot of time.

When using Smart Setup Station for offline changeover, operators set aside the parts needed and automatically rewind parts that are not necessary. This reduces the work time because it does not require to check the changeover list.

Complete Set up of Feeder Position

When setting the parts on the feeder and scanning the part ID, Nexim provides guidance where to set the feeder on the feeder pallet or MFU. The feeder shows the color of the slot number displayed on the monitor of Nexim. As such, it changes to indicate the setting of feeder is complete. Consequently, operators can perform feeder setting work correctly without guessing. This is because of the complete set up of the feeder position and operators visually checks them based on the change of colors.

Scanning the ID barcode of the feeder pallet or the set up MFU enables the worker to check the line. Furthermore, this goes the same to machine where to set the feeder pallet or MFU.

In addition, if there is a long interval between the completion of offline changeover and starting online changeover, and there is need to check whether feeders have been moved before setting the feeder pallet or MFU in the machine. Thus, the worker can easily check it by connecting the feeder pallet or MFU to Smart Setup Solution and selecting the work menu.