ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Fusion of AI, AR Offers Unique Manufacturing Approach

Digital technology is playing significant role in the transformation of manufacturing industry. Consequently, it is creating integrated approach of human-machine approach to manufacturing.

For example, Taiwan 3D vision systems and artificial intelligence (AI) company SOLOMON Technology Corporation and U.S. augmented reality (AR) glass maker RealWear, Inc. have collaborated for an AR application in smart manufacturing solutions. Hence, this will bring in human-machine collaboration, which offers connected systems to increase productivity and avoid costly mistakes in manufacturing.

AI Enhances AR Experience

AR makes use of Simultaneous Localization and Mapping (SLAM) algorithms to compare visual features between camera frames. Generally, this maps and tracks the environment, hence requiring manual verification and real person confirmation and guidance. However, SOLOMON leverage AI algorithms to offer AR features like enhanced interaction with the surrounding physical environment to provide more advanced functionality.

Implementing AI enhances the AR experience by allowing deep neural networks to replace traditional computer vision approaches and enable features such as SOP validation, defect inspection, parts counting, optical character recognition (OCR), identification, and classification.

“(AR) utilizes the dexterity of humans in production lines to handle tasks that are difficult to automate. Specifically, this reduces human error through third party verification and production records. It also reduces dependence on highly trained operators and digitize technological skills reduce risk of employee turnover,” said Cheng-Lung Chen, President at SOLOMON, in discussing the advantages of modern AR.

“In addition, (modern AR) also optimizes desired aspects of operations without complicated and time-consuming system integration,” Chen added.

The SOLOMON solution in RealWear’s AR glasses features audio control that supports up to 14 languages and eight-hour battery life. Weighing 380g, it comes 100 percent hands free, enabling use in challenging environments.

The application of Solomon AR solution in conjunction with AI has enabled new possibilities use cases in various industries.

Suits Defect Inspections

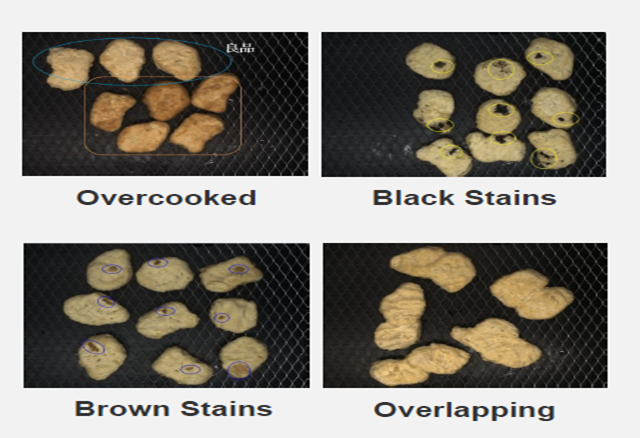

The AR glasses helps identify different defects on processed nuggets passing through a fast-moving conveyor system during mass production and locate the defective products in real-time.

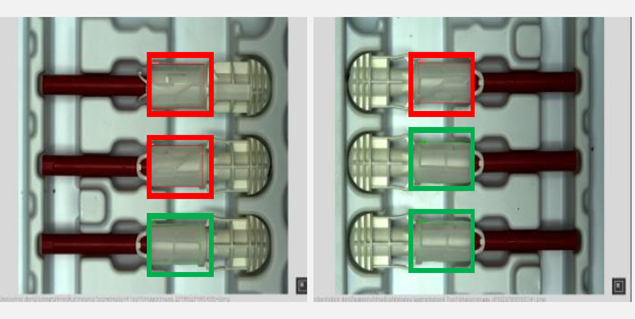

Safety syringes are often of transparent or white plastic material that make them hard to inspect. Hence, AI can learn different textures and patterns to check for assembly errors and implement effective quality control.

While they are complex and irregular, weld beads are hard to inspect manually due to the inconsistency. Here, AI can learn different defect characteristics to identify faulty beads and pick them out for the repairing process.