ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Techman Robot Upgrades TM Robot S Series

Techman Robot made a grand comeback at iREX. It showcased manufacturing applications of human-robot collaboration, rapid integration with palletizing and welding operators, and collaborative robot (cobot) integration with artificial intelligence (AI) vision.

The company will soon launch the upgraded TM Robot S model. This new series will feature comprehensive hardware and software enhancements and smarter integration with vision and peripheral software. It will have a more intuitive human-machine interface and safer human-machine collaboration, suitable for a variety of industrial applications. Thus, the upgraded model is ready to fulfill customers’ needs for smart manufacturing.

AI Vision Solution

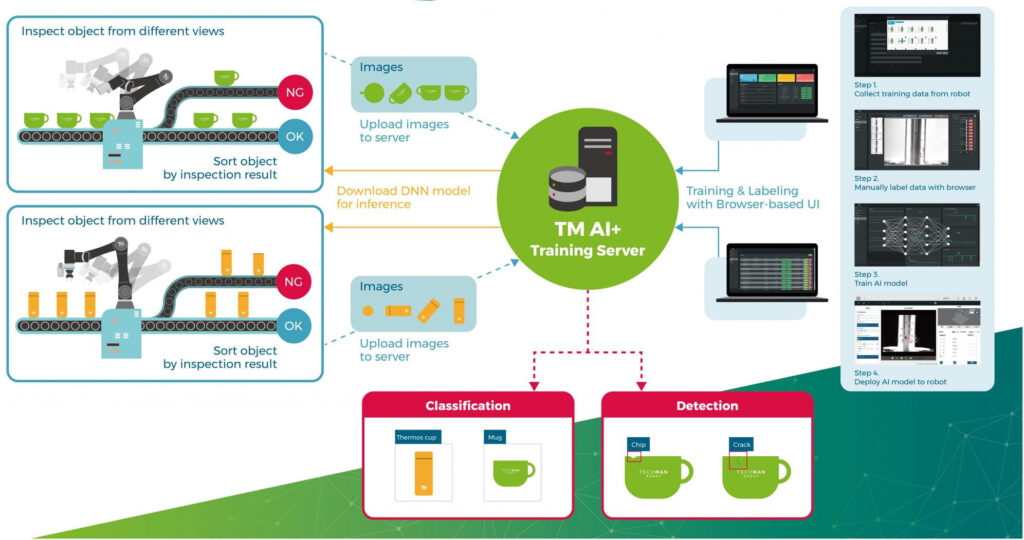

Techman Robot also developed the TM AI+ as an artificial intelligence (AI) vision solution. This software can be used both alone and with the built-in vision system of TM Robot. Because of this function, the robot has evolved into an intelligent collaborative robot with AI recognition.

TM AI+ is the cobot industry’s first integration of traditional machine and advanced AI vision in a single robotic system. It can help solve problems, including vision recognition, barcode reading, OCR, image classification, and assembly. Today, TM AI+ is used in the quality control of Japanese automobile manufacturers and is also implemented in the product identification of pizza and fried chicken chains. From automobile to food applications, TM AI+ can be applied in a wide range of industries.

In addition to the original collaborative robot series, Techman Robot said it will continue to develop total solutions to help close the automation gap for every business, such as the welding operator.

Techman Robot’s exclusive welding operator interface helps users meet their welding needs of different shaped workpieces. It is compatible with well-known welding companies OTC and Panasonic. Also, it can be controlled directly through the robot interface, and is no longer limited by the traditional way of using welding robots. Thus, it can provide visual-assisted positioning function and hand guiding to teach welding on points and tracks intuitively and quickly. This offers Japan and global system integration suppliers the possibility of using TM Robots to develop more welding applications.

Upgraded TM Robot S

Techman Robot will be launching the newly upgraded TM Robot S Series in April 2022. This series has enhanced the safety of human-machine collaboration over the current models. It has passed European and American safety certifications and is the industry’s most advanced collaborative arm with 31 safety certifications—the highest in the industry.

In response to various industrial applications, Techman Robot has upgraded the dust and water resistance level of the S Series. Also, it has launched a newly developed robot teach pendant to make teaching and deploying robots easier and faster. More hardware upgrades will be announced in April.

In addition to hardware upgrades, Techman Robot’s innovative human-machine interface, TMFlow, has been completely revised and upgraded to version 2.0. Thus, this provides a more intuitive operating experience. In addition, a powerful offline programming software can be used for application path simulation and cycle time calculation.

The TM Robot S Series have both new software and hardware upgrades to quickly assist customers in creating collaborative robot solutions for various needs.

Prospects on Japanese Robot Market

According to Japan Robot Association (JRA), the post-epidemic era has driven automation transformation. Specifically, the demand for automation is growing in Europe, the United States, and Japan. In 2021, Japan’s industrial robot orders will increase by 29.6 percent year-on-year to 940.5 billion yen (US$7.77 billion), showing growth for the second consecutive year.

Techman Robot is optimistic about the development of automation. Thus, it will continue to build up distributors and system integrators, and expand its sales network to 25 partners in Japan. In the second half of 2022, Techman Robot will establish a Japanese technical service department to assist Japanese customers to quickly deal with implementation and after-sales service.

Looking upon 2022, Techman Robot will release the newly upgraded TM Robot S. It will continue to recruit system integrators on semiconductor, electronics, and welding fields to jointly explore the Japanese market. With AI vision, and an intelligent factory management system, Techman Robot will assist enterprises to the future of smart manufacturing.