ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Robotics’ New Business Pitch Makes Mark

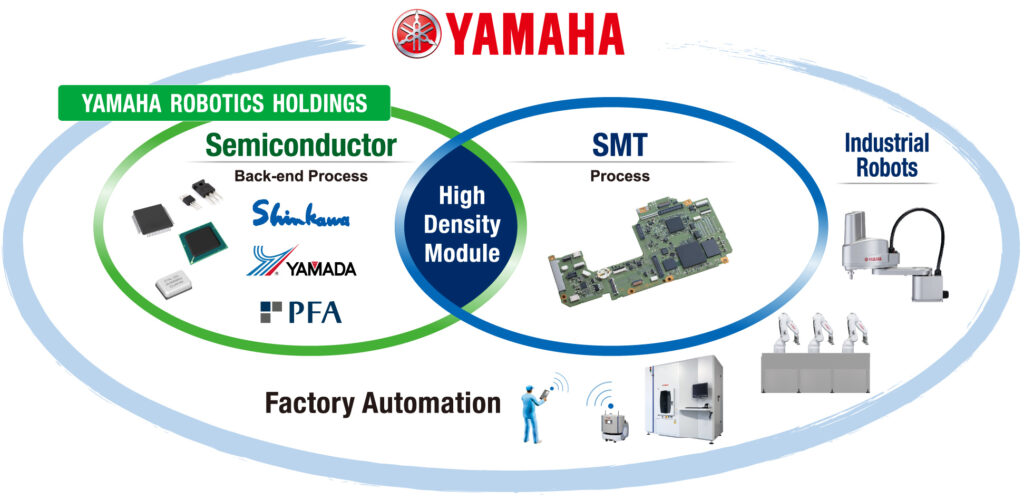

The merging of the semiconductor backend processes and the SMT businesses paved the way for Yamaha Robotics Holdings Co., Ltd. (YRH) in 2019.

The company has made strategic moves for the past three years. For that reason, its growth strategies have been anchored towards expansion of the business.

Particularly, among the strategies include new facilities in Japan and other countries and enhanced mechanism for common components purchases. In addition, it has also been improving on the structure of developing new products, leveraging on technological synergy.

YRH has Yamaha Motor Co., Ltd. as parent company. Accordingly, Yamaha Motor’s main businesses are surface mounting equipment and robots. Consequently, it established YRH in July 2019 because of business integration of Shinkawa Ltd., APIC YAMADA Corporation, and PFA Corporation, a semiconductor inspection equipment.

Strengthens Local, Overseas Presence

The company has been expanding its businesses led by Toshizumi Kato, Chairman & Director of YRH, and Ryosuke Nakamura, President & Representative Director.

Accordingly, the integration of semiconductor backend and SMT processes enabled YRH to provide one-stop solution for customers, said Kato. Since its foundation, Kato said YRH has focused in the promotion of common components procurement and opening of facilities in Japan and abroad. In addition, the company has also focused effecting structural reforms.

“Recently, we have come to demonstrate synergetic effects of the four companies (that made up YRH). Starting the fourth year, we will turn growth strategies toward the expansion of businesses,” said Kato.

YRH made positive turnaround in its business performance of the term ending Dec. 2021. Thus, contributing to the overall performance of the Yamaha Motor group. Immediately, YRH consolidated 19 overseas subsidiaries to 10 subsidiaries after its inception. Currently, it has one each in Taiwan, the Philippines, Vietnam, Singapore, Malaysia, and Thailand. In addition, it also has one each in Lushan, Shenzhen, Shanghai, and Suzhou all in China, and another one in Korea. In June 2021, the company changed the names of these overseas subsidiaries to include Yamaha Robotics.

YRH has also reconstructed its production system. For example, it has commissioned SHINKAWA’s bonder production to Robotics Operations of Yamaha Motor. Moreover, the company opened showrooms at Suzhou and Shenzhen subsidiaries in China, and set up laboratories in Suzhou, Shenzhen, and Taiwan.

The company relocated Shinkawa Taiwan Co., Ltd. in Taipei to Hsinchu, and made it into a laboratory. Taiwan Laboratory came with a clean room and installed with equipment required for the development of leading-edge processes and devices, evaluation of materials, and the development of equipment.

Fortifies Sales Channels, Distribution

To strengthen its capabilities in the overseas market, YRH has added distributors of SMT machines. Particularly, Yamaha Motor’s WKK in Hong Kong and Mass Co., Ltd. in Japan are among the distributors, adding to the existing sales channels of Shinkawa, APIC YAMADA, and PFA.

Kato said, “We have been advancing cross sales, whereby group companies operate cross-sectional way, by unifying the business flow, such that APIC YAMADA sells SHINKAWA’s products. We have been taking the same approach for SMT distributors as well, and it has already started to produce results. At the same time, we step up direct sales to leading customers.”

YRH proposed Development of Chip-on-Wafer Direct Bonding 3D Stacking Integration Technology for Post-5G as a next-generation bonding technology. In fact, the New Energy and Industrial Technology Development Organization (NEDO) has adopted it as one of the development topics for its open-call project. Particularly, for research and development of enhanced infrastructures for post-5G information and communications systems and developing technologies for manufacturing leading-edge semiconductors.

The National Institute of Advanced Industrial Science and Technology and Tokyo University of Science will participate in the technological development as joint research partners, and SHINKAWA will conduct some of the development.

The technology supports sixth generation (6G) mobile communications that require even more advanced high-speed signal transmission performance. In addition, it integrates multiple semiconductor chips, including ultrathin chips, by joining them with high productivity and high yield. YRH targets to put it to practical use after three years of development.