ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

AUO Earns Accolade for Smart Production Line

AUO Corporation has received recognition from the ROI-EFESO INDUSTRIE 4.0 AWARD in its Smart Automation category for the company’s Taichung Fab 3 facility. Particularly, this is because AUO has integrated AIoT to promote automation and high-efficient management systems.

With its strong fundamentals in smart manufacturing to solve process pain points, AUO was able to improve manufacturing and production efficiency. Owing to its abundant energy for digital transformation, AUO has become the first corporation in Taiwan to earn the ROI-EFESO INDUSTRIE 4.0 AWARD. In addition, it is also the first global display manufacturing corporation recognized for this feat.

Combines Multiple Smart Technologies

Established in 2013, the ROI-EFESO INDUSTRIE 4.0 AWARD is one of the most renowned awards in the Germanosphere. In essence, it employs significant benchmark for the digital transformation of industries that recognizes corporations with outstanding contributions and digital transformation solutions.

“For a long time, AUO has dedicated itself to improving the resilience of its factory production lines,” said Ting-Li Lin, Senior Vice President of the Manufacturing Group at AUO.

In addition, Lin said, “Onwards, AUO will accelerate the cultivation of omni-talented professionals, exert its potential in green manufacturing. (At the same time), quickly duplicate the success of Taichung Fab 3 to other plants in providing smart solutions.”

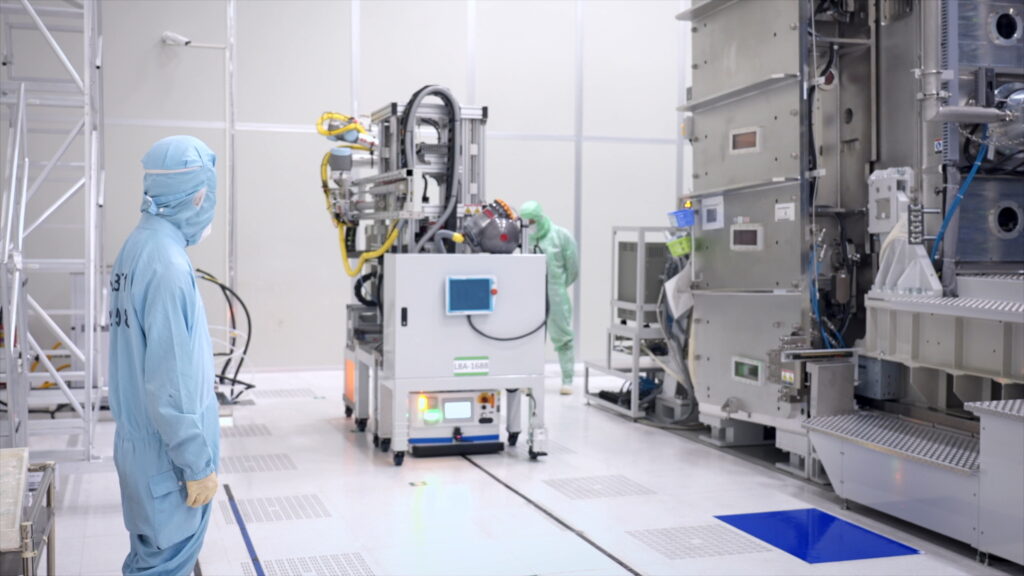

ROI-EFESO INDUSTRIE 4.0 AWARD jury member Dr. Niels Syassen, Member of the Executive Board at SICK AG, stated, “AUO’s Industry 4.0 solution is a lodestar for contemporary consumer goods manufacturing in technologically demanding and highly volatile markets. It combines multiple smart automation technologies: AIoT and Big Data analytics support store floor management, for example, while Autonomous Mobile Robots comprehensively automate material provisioning and setup changes. The result is a unique Industry 4.0 infrastructure for economically and ecologically oriented display manufacturing.”

Six Major AIoT Technologies Driving Smart Factories

AUO gradually develops toward full automation manufacturing processes and human-robot collaboration to improve production efficiency. Particularly, it integrates manufacturing sites with the Cyber-Physical System (CPS) through the six major smart technologies. Namely, these technologies are smart automation, Internet-of-Things (IoT), predictive maintenance, smart imaging, data science, and self-feedback. They support decision-making and to grasp information in making proper corrections in real-time accurately.

For one, the CPS improves production efficiency and satisfies the needs for high-mix, low-volume, and highly customized products. AUO steadily works toward an autonomously running and self-adaptive Industry 4.0 sustainable smart factory.

Combines Automation with AGV/AMR

AUO combines its production lines with IoT, big data, optical identification technology, automated guided vehicles (AGV), and autonomous mobile robots (AMR). Moreover, using human-robot collaboration, it replaces conventional technologies in its operations and in reviewing automated integrations such as automatic data comparison and parameter adjustment. These replacements have simplified the changeover process in manufacturing and reduced the overall manual working items by 80 percent from 2018 to 2021, significantly improving production efficiency.

Digital Twin Driver Systems for Efficient Production

In the production process, the inspection of product information and machine status in production lines is time- and labor-consuming. Digital twin-driven management systems integrate data for analysis, simulation, prediction, and control for anomaly alerts and troubleshooting, achieving system integration and full-time monitoring for effective enhancement of data processing. The systems are the key facilitators in the high-efficiency management of smart factories, responsible for the 16 percent improvements in factory equipment efficiency and the 36 percent increase in overall production yield from 2018 to 2021.

Smart Energy Achieves Net-Zero Carbon Emissions

Facing extreme weather challenges, AUO uses sensors to collect data for energy consumption prediction analysis. Thus, integrating data and transferring the prediction results back to the energy management center to monitor and respond to anomalous energy and resource consumption in real time. Most importantly, this procedure has successfully reduced water usage by 27 percent and material waste by 30 percent in the four years from 2018 to 2021. Thus, moving toward the goal of net-zero carbon emissions.

Since being selected for “Global Lighthouse Network” by the World Economic Forum and recognized in the Manufacturing Leadership Awards last year, AUO earns another recognition. Thus, exhibiting its determination to lead the industry for transformation and effect the digital revolution. AUO insightfully observes trends in the industry, takes preemptive action in the realization of full autonomy from automation, and flexibly uses new technologies to facilitate digital transformation. For that reason, able to promote value chain coordination and continuously improves its green production technologies.

AUO constantly leads its valued partners in the industry and introducing innovative capabilities in smart manufacturing to the world in creating a smart ecosystem for the common good.