ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Dürr Designs Modular MOM System for Smart Factory

To make smart factory a reality, machines and systems from all sub-areas must communicate with each other, then achieve end-to-end digitalization. The Dürr Group uses its manufacturing and digitalization knowledge to combine hardware and software. Together, Dürr’s software specialists and the Group subsidiary iTAC developed a modular solution for manufacturing planning, execution, control, monitoring, optimization, and predictive analysis.

Instead of monolithic individual solutions, the new Manufacturing Operations Management (MOM) system relies on microservices that provide functionality as required. The solution enables a high level of flexibility and consistency and offers many interfaces in terms of interoperability.

The two companies will display how this works at the Hannover Messe trade fair in Hanover, Germany, from April 17 to 21, 2023, in hall 15, booth E34.

Components of a Digital Factory

There are three central superordinate control components in every digital factory: Manufacturing Execution System (MES) controls and monitors production; Supervisory Control and Data Acquisition (SCADA) collects and analyzes data; and Human Machine Interface (HMI) visualizes production and process flow. Until now, these components, for example, the MES sub-segment, were mostly designed as stand-alone solutions.

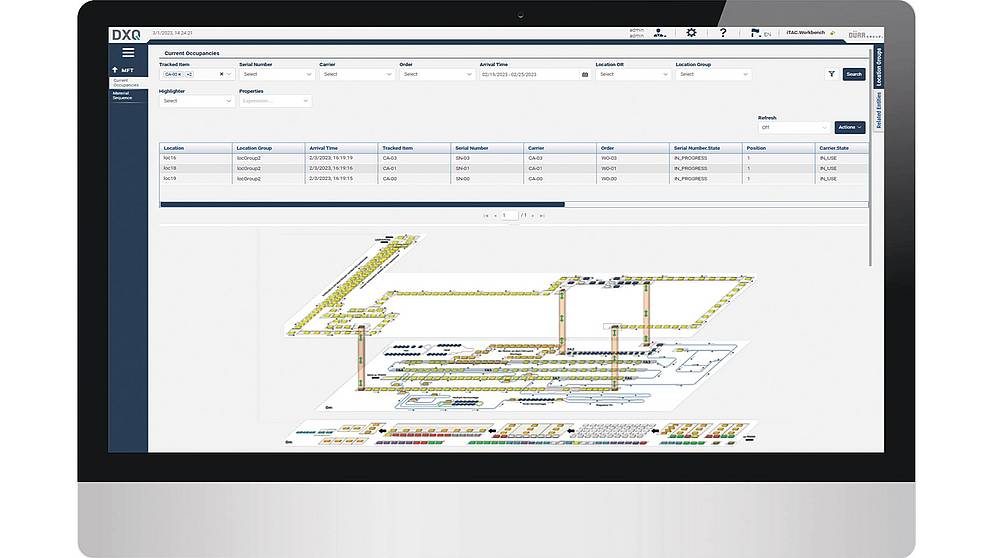

Dürr and iTAC have combined their competencies and merged the functional scopes of MES, SCADA, and HMI into a uniform MOM architecture. This was made possible by combining Dürr’s DXQcontrol product family with iTAC’s iTAC.MOM.Suite. Thus, manufacturing companies, whether manufacturers or suppliers, receive a future-proof industrial digitalization solution with interoperable modules that cover all smart factory functionalities.

Microservices Architecture for Agile Manufacturing

Previous MES solutions are monolithically structured. This means that a single software product encompasses different functionalities, such as data acquisition or logistics. Thus, Dürr and iTAC’s MOM architecture takes a modular approach. Multiple microservices act and communicate with each other while performing their tasks independently. Unlike monolithic solutions, microservices have self-sufficient data storage and open interfaces for communication with other services for flexible deployment. Only necessary modules are installed, making operation more sustainable, as fewer servers are required. The MOM architecture’s modular structure is also less error-prone than monolithic architectures, increasing plant availability.

Variable Availability: Cloud, On-site, or Hybrid

Microservices can be flexibly installed on IIoT platforms in the cloud, on-site (on-premises), or in hybrid factory deployments. Customers can use specific cloud services while rolling out other functionalities on-site if there are operating costs or production stability concerns, for example.

The hybrid solution is particularly advantageous for large data volumes in the terabyte range. Processing some of the data locally (“on-edge”), i.e., within the local environment, saves time, costs, and energy because not all data sets have to be transferred to the cloud/IIoT platform via many transactions. In addition, local processing brings the necessary speed to control manufacturing processes in real-time.

Sustainable Production Management

Dürr and its subsidiaries iTAC Software AG and Dualis GmbH IT Solution will present other industry development trends in addition to the MOM presentation at the Hannover Messe trade fair. Another focus is on sustainable and energy efficient production management. Dürr will present its ISO 50001-certified DXQenergy.management software that maps media consumptions throughout the production line, systematically detects consumption anomalies, and consequently identifies potential savings. The GANTTPLAN planning tool from DUALIS monitors energy costs incurred during production planning.

Manufacturing Analytics and Intelligence

Dürr and iTAC’s analysis tools are all about using artificial intelligence to improve production quality and availability. They can act as MOM system components. The products evaluate production and quality data. These data detect possible defects or impending wear and use machine learning to make forecasts. Prevention and prediction services and the integration of edge technologies result in optimization, increased added value, and data sovereignty.

Advanced Planning and Scheduling (APS)

The Group offers intelligent tools from Dürr, iTAC, and DUALIS as an overall solution for the APS field. These tools plan and optimize production order execution, consider available resources and capacities as well as material requirements and necessary maintenance intervals. The solution has many benefits, such as short delivery times, high delivery reliability, and permanent cost optimization.

Joint trade fair appearance of Dürr, iTAC, and DUALIS

More than 4,000 exhibitors will present their solutions on current trends at the major industrial trade fair in Hanover, Germany, where the digitalization of production plays a central role. Dürr, iTAC, and DUALIS will present end-to-end solutions for a smart factory at their joint booth (hall 15, booth E34) in line with the theme “Real industrial transformation. Digitize today. Enable tomorrow.”