ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SK Hynix to Use Infinitesima’s New Metrology Tool

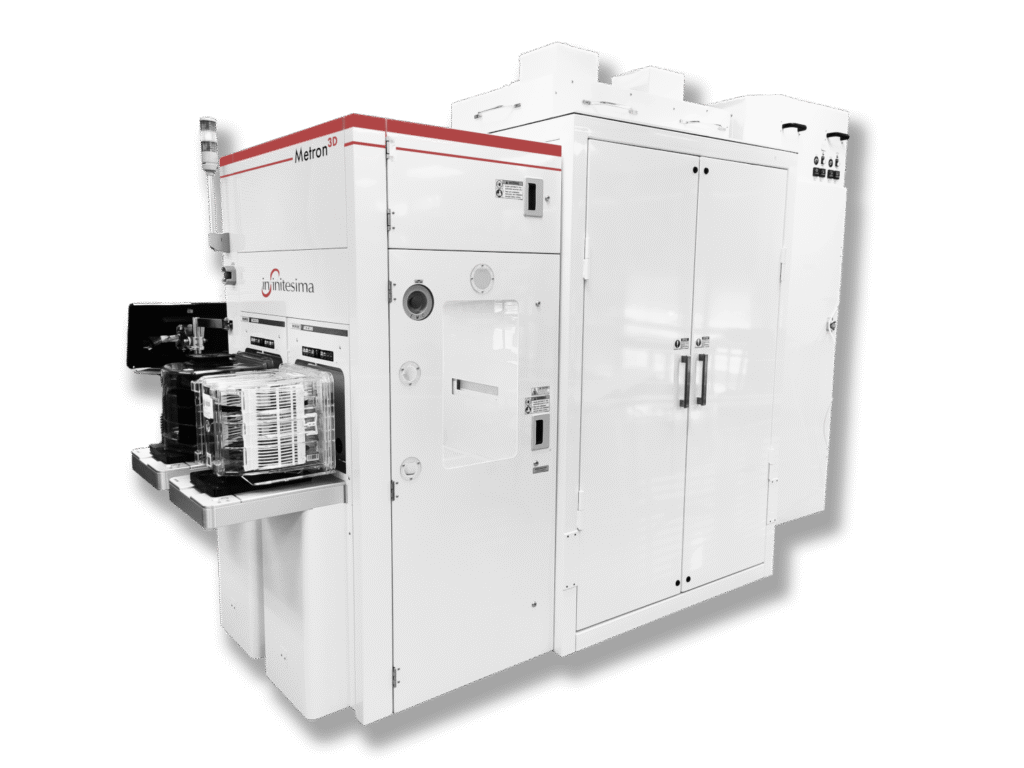

Britain-headquartered Infinitesima said Korean chip supplier SK Hynix will use its latest Metron®3D 300mm in-line wafer metrology system for its DRAM production. According to Infinitesima, their Metron®3D provides 3D process control with sub-nanometer accuracy that will be crucial for SK Hynix’s next-generation memory devices.

The release of the system to SK Hynix’s production follows an extensive evaluation period, applying the system for characterization across multiple process steps.

Ensures High Yield in Advanced DRAM

In essence, wafer metrology systems in DRAM manufacturing play important role in precisely measuring and analyzing various parameters of silicon wafers throughout the production process. Therefore, these measurements are crucial in ensuring the quality, reliability, and performance of DRAM chips.

Recently, 3D dimensional process control at the nano-scale level is becoming increasingly important. One reason of which is this ensures high yield in advanced DRAM processes. For that reason, DRAM manufacturers need to have an excellent sub-nanometer 3D metrology to ensure quality yield in advanced DRAM processes.

“Infinitesima’s Metron®3D has demonstrated excellent sub-nanometer 3D metrology with the required cost-of-ownership necessary for HVM implementation,” said Young-Hyun Choi, Head of Defect Analysis, Metrology and Inspection Technology at SK Hynix.

What makes Metron®3D special is it features Infinitesima’s proprietary Rapid Probe MicroscopeTM (RPM) technology. Particularly, it provides measurement capability at 10× to 100× typical Atomic Force Microscopy (AFM) throughput.

Furthermore, the system’s capabilities also include fully automated wafer, data, and probe handling, making it optimal for in-line volume production of semiconductor devices. The investment in this metrology solution highlights SK Hynix’s commitment to maintaining technical leadership in the development and manufacture of computer memory.

HVM Ready, Crucial to Modern Chip Manufacturing

According to Infinitesima, the Metron®3Dcombines the well-established benefits of AFM with fundamentally new invetions that increase the throughput by at least 100 times and probe lifetime by 10 times.

The ability to operate at such high speed while maintaining very high accuracy permits chipmakers to benefit from process insensitive 3D surface profiling for in–line metrology and inspection applications for the first time.

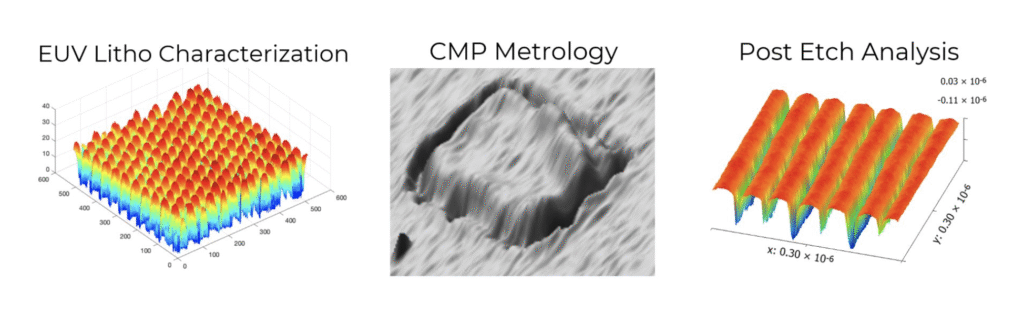

The Metron3D platform enables critical metrology and inspection capabilities that are required to advance semiconductor process control for maximizing yield and lowering wafer costs. As dimensions shrink and device architecture becomes more complex, the Metron3D offers measurement advantages in areas such as CMP performance – both local and long range, EUV Resist characterization and Logic FEOL analysis.

10 July 2025