ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

HORIBA Provides Total Solution for IC Process from Lab to Fab

HORIBA Group’s core technology is to measure, ranging from gas flow control tech-nology, infrared measurement, spectroscopic analysis, particle diameter distribution analysis to electrochemical analysis. With measurement at its heart, HORIBA has contributed to all industrial fields, encompassing from monitoring and control, quality management, environment measurement to exhaust gas and drainage treatments of customers’ production processes. Among these, HORIBA believes it can make a huge contribution to the development of the semiconductor industry.

At SEMICON Korea 2023, HORIBA will display its wide range of measurement solutions, carrying the theme “Lab to Fab, HORIBA ALL Around”.

In recent years, HORIBA Group has been stepping up support for semiconductor manufacturing in an omnidirectional manner. In this effort, the group aims to cover the entire semiconductor plant from process monitors, such as vacuum meters and residual gas

analyzers; reticle/mask particle detection systems; exhaust gas and drainage measurement equipment; to contaminant substance monitoring in clean rooms; in addition to mass flow controllers and chemical concentration monitors it has offered since earlier.

This article introduces HORIBA’s products that can contribute to accurate monitoring and control of vacuum condition in chambers, and its latest model, the DO-120 dissolved oxygen monitor, which can monitor dissolved oxygen in specific chemical solutions.

Chamber Health Monitoring

With advances in semiconductor device fine-pattern processing and circuit integration technologies, semiconductor manufacturing processes have become complicated. These trends have heightened the importance of monitoring of various parameters, such as pressure, plasma, and temperature in the manufacturing processes to steadily provide high-quality silicon wafers and the importance has been building up. HORIBA considers that its analysis and measuring solutions contribute greatly to these needs.

At SEMICON Korea, HORIBA will introduce the new QL-SG02 quadrupole mass analyzer micropole system (Photo 1), which can measure the condition of gases in the vacuum chamber as partial pressure. QL-SG02 measures the mass of gases floating in the chamber after opening the chamber or prior to the process to control conditions. It features almost twice the measurement speed of gas particles of the previous model, thus enabling setting in accordance with measurement environment. HORIBA revisited the calibration method of sensors, thereby reducing variations in the sensitivity of sensors at the time of replacement to about half of the previous system.

The company will also exhibit the VG-200S capacitance manometer (Photo 2), a compact model for the international market, which constantly monitors the pressure of the chamber. Adopting the company’s original electrode structure, it achieves high-accuracy, high-stability measurement of pressure.

The IT-270 infrared thermometer will also be on display. This tool incorporates HORIBA’s high-sensitivity thermopile sensor and is capable of real-time monitoring of temperature in the chamber with high accuracy.

Moreover, the company will display the EV2.0 Series optical emission spectroscopy, which analyzes emission spectrum of plasma, detects end point, and controls plasma conditions in the thin-film process using plasma.

Monitors Dissolved Oxygen in Chemicals Used For Wafer Etching

It is known that the dissolved oxygen (DO) in chemicals has an effect on the etching rate. For example, in the case of the silicon (Si) etching by TMAH (Tetramethylammonium hydroxide), the etching rate of SiO2 formed when Si is oxidized by DO, is slower than Si. Thus, controlling the DO concentration in TMAH is one of the key parameters of controlling etching rate.

Recently, demands for monitoring DO have increased, including for non-aqueous solvents or NH3 solutions. HORIBA has provided a DO concentration monitor based on the Diaphragm Polarographic Method. Here, a membrane separates the electrochemical sensor from the sample solution. Oxygen dissolved in sample permeates through the membrane and is reduced at the cathodic electrode surface. DO concentration is calculated from the cathodic current. The company’s existing DO monitor, DO-110, can measure DO in etching solutions like TMAH and diluted HF at 60°C. However, DO-110 cannot measure DO in etching solutions based on solvents with a higher boiling point than water or NH3 solutions be-cause of the vaporization and changes in the properties of the internal solution in the sensor. HORIBA has developed a new DO concentration monitor, DO-120, that can measure these chemicals by supplying the internal solution from an external reservoir to the sensor to replenish the volume lost by vaporization and to mitigate any changes to the properties of the solution in the sensor.

The new DO concentration monitor (DO-120) has the following features:

Flexible installation

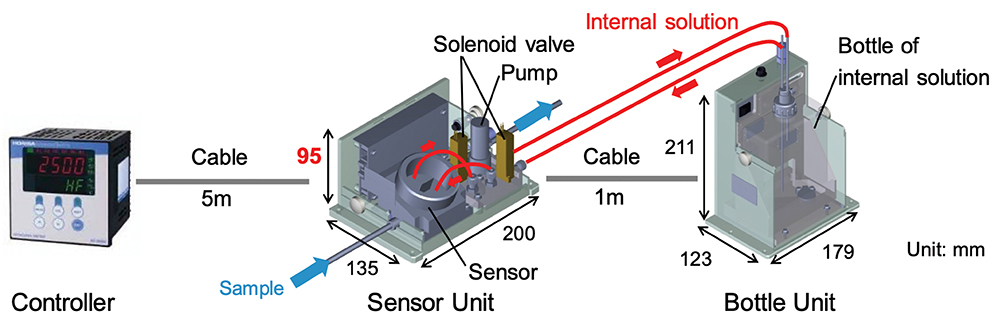

Figure 1 shows the configuration of the new DO concentration monitor (DO-120). The bottle unit with internal solution (KCl + pH 7 buffer aqueous solution) is separated from the sensor unit to make its size compact. The internal solution is transported by a pump installed in the sensor unit automatically. The distance between the sensor and bottle unit can be up to 1m and the installation is flexible.

Longer sensor lifetime

The degree of vaporization and change in the properties of the internal solution vary by the type and concentration of the chemicals being measured. HORIBA has researched DO monitoring in non-aqueous solvents and NH3 solutions used for wafer etching. In the case of solvents with a higher boiling point than water, vaporization of moisture in the internal solution to outside of the sensor is caused by difference of vapor pressure between the internal solution and the sample. It is necessary to replenish the amount the internal solution lost to vaporization. In the case of NH3 solution, the change in properties of internal solution is caused by gas penetrating the membrane and accumulating inside the sensor increasing the pH of the internal solution. The failure mode is that silver (Ag) is deposited on the DO sensing electrode when pH of the internal solution is more than 8.5. Taking into account the vaporization rate and change in properties of internal solution, the company had determined the volume and the circulation rate of the internal solution.

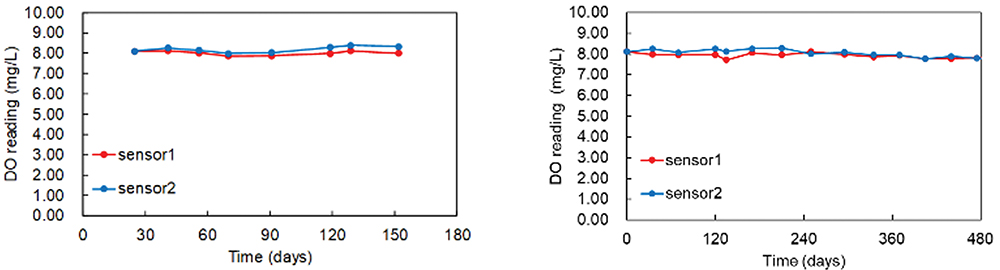

Figure 2A shows the result for a solvent with a higher boiling point than water. When using DO-110 at 60°C, measurement error in signal intensity happened in 1 month. When using DO-120, the signal intensity is stable for 5 months within 1% vs full scale (full scale is 20mg/L). This result indicates that DO-120 can stably and continuously measure DO concentration in solvents with a higher boiling point than water. It is assumed that DO-120 can measure DO concentration of these solvents for longer periods when properties of the internal solution do not change.

Figure 2B shows the result for NH3 solution. When DO-110 was immersed in 28% NH3 solution at room temperature, the error in signal intensity happened in 5 days. When using DO-120, the signal intensity is stable for 12 months within 1% vs full scale. This result indicates that DO-120 can stably and continu-ously measure DO concentration in NH3 solution for 1 year.

HORIBA will contribute to further development of the semiconductor industry as a solution provider and a best partner for customers.

These solutions will be available at HORIBA’s booth at SEMICON Korea.