ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Viscom Lineup Propels Advanced Quality Control

Printed circuit board assemblies (PCBAs) and integrated circuits (ICs) are the focus of NEPCON Asia from October 11–13, 2023, in Shenzhen, China. Incidentally, Viscom AG will make its presence felt at the event through its select teams in the territory.

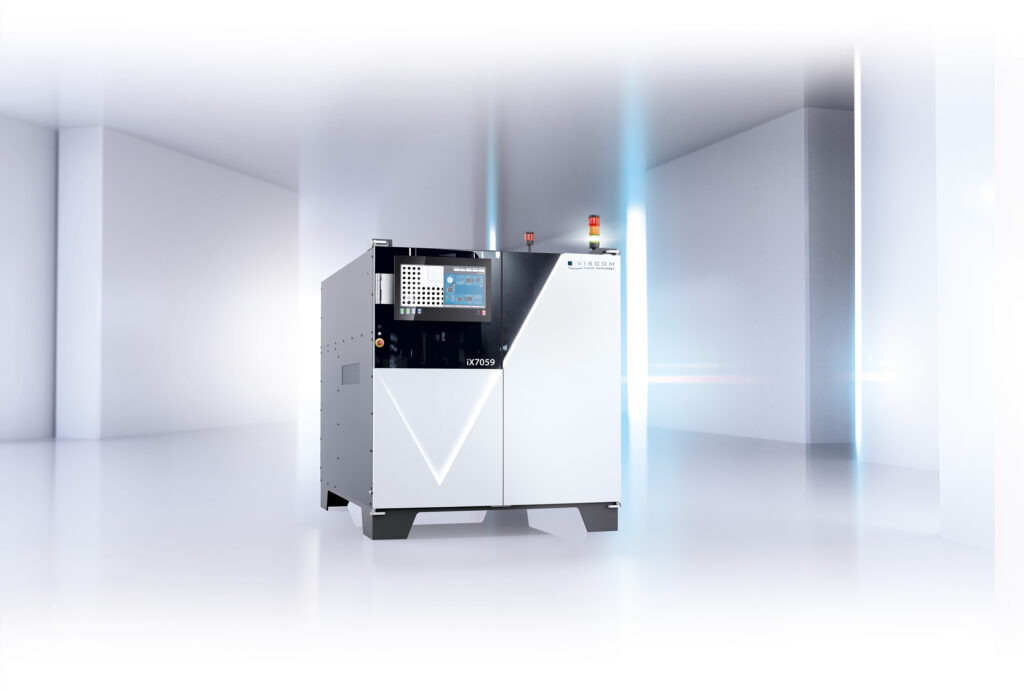

Most importantly, the company will showcase its advanced inspection systems. Namely, the S3088 ultra chrome for 3D SPI and S3088 ultra chrome as a 3D AOI configuration. Also, the company will highlight iX7059 PCB Inspection XL from 3D AXI portfolio and the X8011-III 3D MXI system.

Exceptional High Throughput

Viscom inspection systems can go well into location-independent, networked processes. Thus, providing new quality-relevant insights through artificial intelligence and a variety of customized algorithms.

Visitors can explore this in detail at the Shenzhen World Exhibition & Convention Center (Baoan New Hall). Viscom will be at booth No. 5D20. Solder paste inspection with an orthogonal optical resolution of 10 μm/pixel and a height resolution of 0.1 µm/pixel can be combined with four angular views. Hence, delivering perfect, shadow-free inspection results.

Automatic post-reflow optical inspection with the S3088 ultra chrome system even offers nine perspectives, true-to-life spatial renderings. Also, exceptionally high throughput in large production areas.

For inline X-ray, customers can choose from a well-designed Viscom product family, depending on their individual inspection needs. Whether for PCBAs with a length of up to 1600 mm or heavy assembled objects weighing up to 40 kg – the iX7059 series offers suitable configurations.

For special tasks such as the inspection of IGBT modules with their ICs for power electronics applications, a 180 kV X-ray tube is available as a component. Meanwhile, different layers of the inspection object can be analyzed with the highest precision.

Where speed is far less important than the particularly brilliant resolution of X-ray results, the 3D-MXI Viscom System X8011-III comes into play. Particularly, the thorough analysis of prototypes, the inspection of product complaints, and the quality control of small batches. These are the many examples of intelligent and effective use of its technological capabilities.

Moreover, automatic reports and networked comparisons of the X8011-III’s X-ray images with inline results from other machines round out this special offering.