ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

onsemi to Offer the Best SiC to Soar Energy Efficiency

In the face of escalating climate crises and a dramatic rise in global energy demands, governments and industries are committing to ambitious climate goals. Specifically, those that aim at mitigating environmental impact and securing a sustainable future.

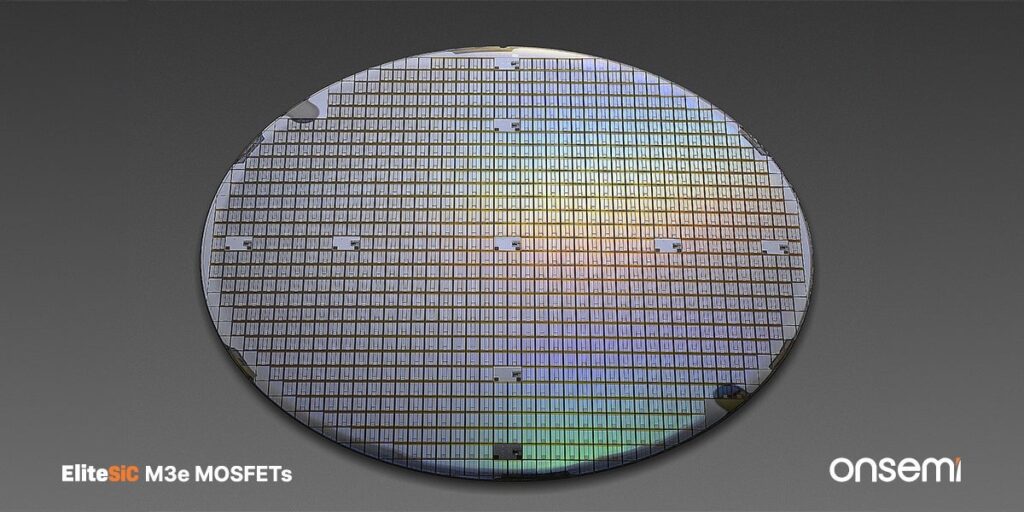

Key to these efforts is the transition to electrification to reduce carbon emissions and embrace renewable energy resources. Most importantly, onsemi has introduced its latest generation silicon carbide technology platform, EliteSiC M3e MOSFETs.

The company also disclosed plans to release multiple additional generations through 2030.

“The future of electrification is dependent on advanced power semiconductors. Today’s infrastructure cannot keep up with the world’s demands for more intelligence and electrified mobility without significant innovations in power. This is critical to the ability to achieve global electrification and stop climate change,” said Simon Keeton, group president, Power Solutions Group, onsemi. In addition, Keeton said, “We are setting the pace for innovation, with plans to significantly increase power density in our silicon carbide technology roadmap through 2030. (This will) meet the growing demands for energy and enable the global transition to electrification.”

Essential for Automotive, Industrial Applications

The EliteSiC M3e MOSFETs will play a fundamental role in enabling the performance and reliability of next-generation electrical systems at lower cost per kW. Thus, influencing the adoption and effectiveness of electrification initiatives. With the ability to operate at higher switching frequencies and voltages while minimizing power conversion losses, this platform is essential for a wide range of automotive and industrial applications such as electric vehicle powertrains, DC fast chargers, solar inverters and energy storage solutions. Additionally, the EliteSiC M3e MOSFETs will enable the transition to more efficient, higher-power data centers. Therefore, will meet the exponentially increasing energy demands that power a sustainable artificial intelligence engine.

Trusted Platform Delivers Generational Efficiency Leap

Through onsemi’s unique design engineering and manufacturing capabilities, the EliteSiC M3e MOSFETs achieve a significant reduction. Particularly, both in conduction and switching losses on the trusted and field-proven planar architecture.

Compared to previous generations, the platform can reduce conduction losses by 30% and turn-off losses by up to 50%1. By extending the life of SiC planar MOSFETs and delivering industry-leading performance with EliteSiC M3e technology, onsemi can ensure the robustness and stability of the platform. Therefore, making it a preferred choice for critical electrification applications.

The EliteSiC M3e MOSFETs also offer the industry’s lowest specific on-resistance (RSP) with short circuit capability. This is critical for the traction inverter market that dominates SiC volume. Packaged in onsemi’s state-of-the-art discrete and power modules, the 1200V M3e die delivers substantially more phase current than previous EliteSiC technology. Thus, resulting in approximately 20% more output power in the same traction inverter housing.

Conversely, a fixed power level can now be designed with 20% less SiC content. This saves costs while enabling the design of smaller, lighter and more reliable systems.

Additionally, onsemi provides a broader portfolio of intelligent power technologies including gate drivers, DC-DC converters, e-Fuses and more to pair with the EliteSiC M3e platform. The end-end onsemi combination of optimized, co-engineered power switches, drivers and controllers enable advanced features via integration, lowering overall system cost.

Accelerating the Future of Power

Global energy demands will likely soar over the next decade. Thus, making the need for increased power density in semiconductors paramount. onsemi is leading innovation across its silicon carbide roadmap – from die architectures to novel packaging techniques. This will continue to address the general industry demand for increased power density.

With each new generation of silicon carbide, cell structures will be optimized to efficiently push more current through a smaller area, increasing power density.

When coupled with the company’s advanced packaging techniques, onsemi will be able to maximize performance and reduce package size. By applying the concepts of Moore’s Law to the development of silicon carbide, onsemi can develop multiple generations in parallel and accelerate its roadmap to bring several new EliteSiC products to market at an accelerated pace through 2030.

“We are applying our decades of experience in power semiconductors to push the boundaries of speed and innovation in our engineering and manufacturing capabilities to meet the rising global energy demands,” said Dr. Mrinal Das, senior director of technical marketing, Power Solutions Group, onsemi.

In addition, Das said, “There is a huge technical interdependency between the materials, device and package in silicon carbide. Having full ownership over these key aspects allows us to have control over the design and manufacturing process and bring new generations to market much faster.”

19 July 2024