ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

ASMPT to Lift its Innovative Bonding in AI, Mobility

ASMPT will present its latest technical innovations in the field of bonding for co-packaged optics components and power modules at the forthcoming electronica 2024. Specifically, the company will once again bring leading experts, users, and manufacturers in its booth.

electronica 2024 is a biennial show, which will take place in Munich, Germany from November 12 to 15.

“Artificial intelligence and electromobility will be the main trends and drivers of technological and economic change in the coming years,” says Dr. Johann Weinhändler, Managing Director of ASMPT AMICRA. Moreover, Dr. Weinhändler is responsible for ASMPT’s Semiconductor Solutions Division in Europe. “These rapidly growing markets place special demands on interconnect technologies in semiconductor manufacturing. With hybrid bonding and silver sintering we are opening up new opportunities in these fields.”

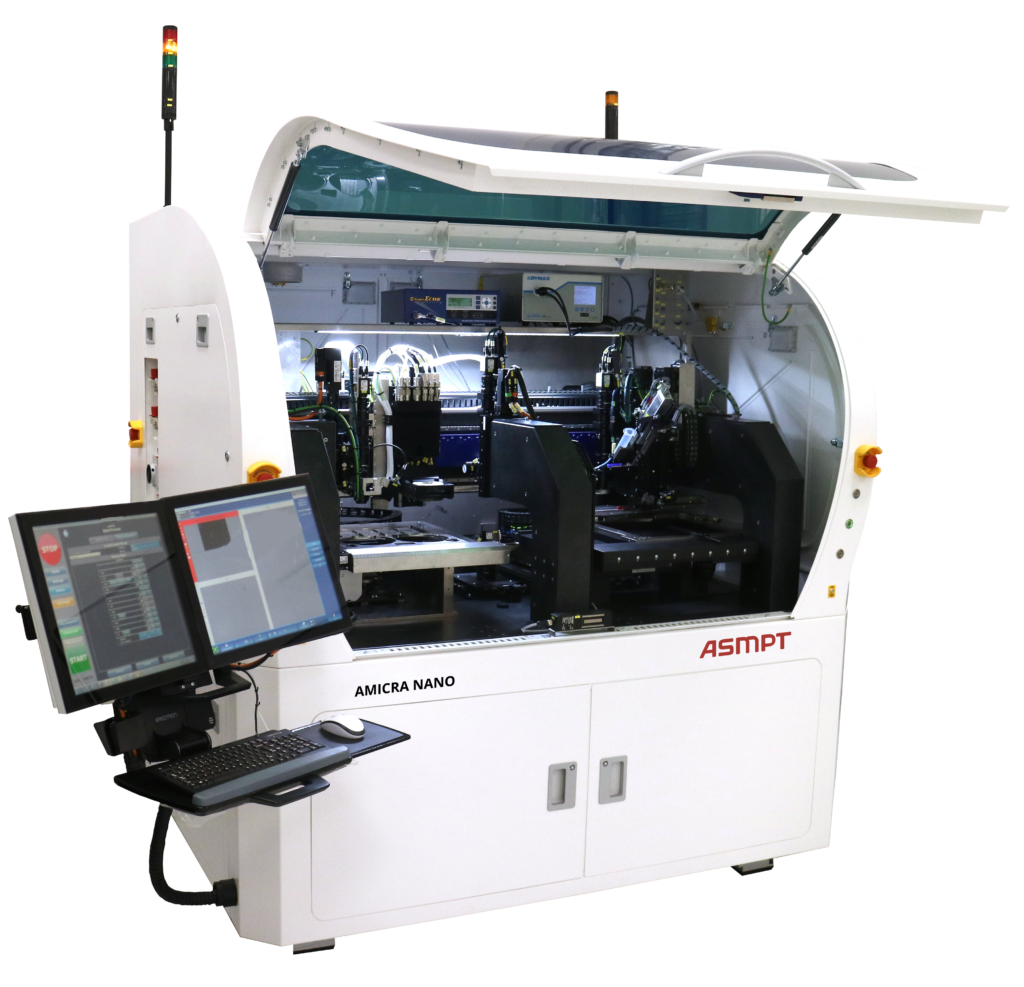

AMICRA NANO: Hybrid bonding for super-fine structures

Exploiting the power of future high-performance computers and AI systems to the fullest requires extremely fast fiber-optic data links. Co-packaged optical components are essential for such connections. Accordingly, the tiny light-emitting and light-receiving components go with an exceptional degree of precision.

Hybrid bonding is the right technology for such highly miniaturized structures. Specifically, it does not require any solder paste or adhesives. In a two-stage process, it is essential to create a chemical bond between two silicon oxide layers. Next, to activate the underlying copper layers through thermal treatment. Thus, they form a mechanically stable and electrically conductive bond.

The highly flexible die and flip-chip AMICRA NANO bonder targets such tasks and will be on display at the booth. With a placement accuracy of ±0.2 µm, several integrated heating systems and a high-purity processing environment, the AMICRA NANO is extremely flexible. Hence, it is possile for use in various bonding technologies.

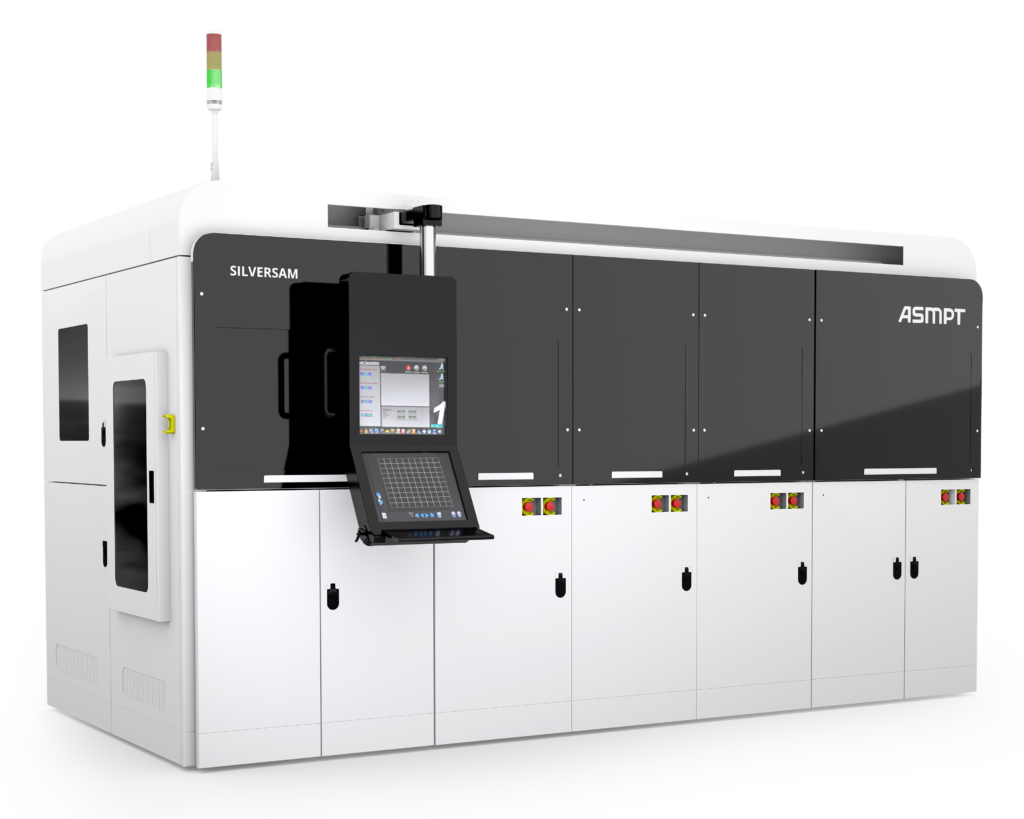

SilverSAM: Sintering instead of soldering

For power modules that must withstand high currents, conventional soft soldering is not always suitable. With videos and sample products, ASMPT will show at this year’s electronica how to use the sintering process to create temperature-resistant and highly conductive connections in power electronics.

The versatile SilverSAM platform uses a combination of pressure, temperature, and time to bond silver particles in the previously applied paste. To protect the components, it is necessary for temperatures to be well below melting point of silver (961°C or 1,762°F). The machine can process different materials such as direct bonded copper (DBC) and active metal brazing (AMB). Moreover, it supports various processes such as wet and dry pastes as well as die transfer films (DTF). With an automatic tool changer and a bonding force of up to 588 N, the SilverSAM delivers high productivity and scalability for the mass production of power modules.

The SilverSAM platform thus combines flexibility, productivity and high sintering quality, making it ideal for applications in modern power electronics.

15 October 2024