ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

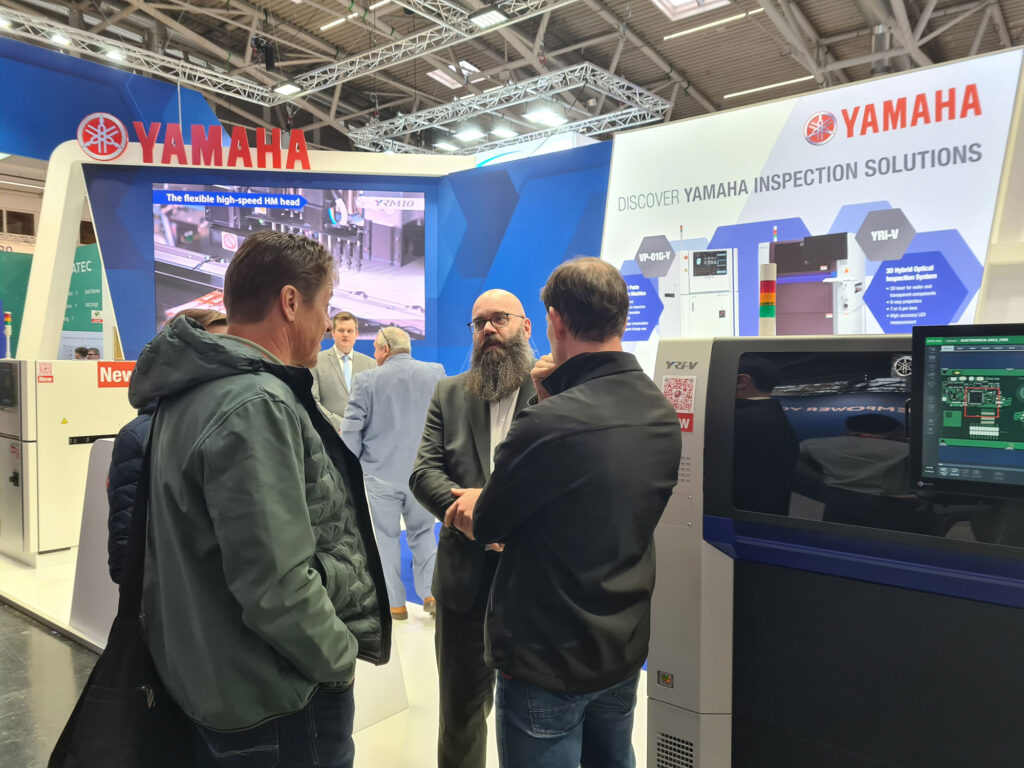

Yamaha Brings New Innovations to electronica

Yamaha Robotics SMT section presented innovations in high-speed surface-mount inspection at electronica 2024. Primarily, it demonstrated the latest AI skills and special features for applications, including LED lighting, e-mobility, and mechatronics.

YRi-V 2D/3D AOI System

Particularly, Yamaha’s YRi-V 2D/3D automatic optical inspection (AOI) systems now come with special features. They simplify checking the alignment and spacing of components such as LED arrays and position detectors. Also, these features help cut the setup time for inspecting densely populated automotive and architectural lighting assemblies, as well as electric drives and mechatronics that contain Hall sensors for brushless motor control.

Moreover, the YRi-V machines also leverage AI capabilities added to Yamaha’s advanced AOI software. Specifically, these accelerate programming and increase inspection accuracy to maximize productivity and strengthen quality control. Programming tools enhanced with AI help populate libraries and add missing component data, cutting the time for new product introduction (NPI) on surface-mount assembly lines. Also, the latest AI skills now bring the power of machine learning to secondary judgements made during production. These provide an automated AOI expert for every assembly line.

Specifically, standard YRi-V systems have a 12MP camera sensor and offer 12µm, 7µm, and 5µm resolution options. At electronica, visitors got to assess the latest YRi-V HS with its 25MP sensor that cuts cycle time by more than 50% at high resolution. The option targets densely populated assemblies such as server cards and communication infrastructure, as well as highly miniaturized products like IoT sensors. Also, the YRi-V HS also adds laser measurement for accurate coplanarity checks on components such as LEDs and chip-scale packages, which have reflective surfaces that make inspection difficult using conventional lighting.

VP-01G- Solder Paste Inspection System

The Yamaha booth also featured the new VP-01G-Y solder-paste inspection system that checks the volume, shape, and positional accuracy of screen-printed deposits before boards enter the mounter for component placement. The VP-01G-Y operates at the line speed and helps automatically optimize print process settings, stencil cleaning, and paste condition.

“Exhibiting at electronica enabled us to meet new potential customers and demonstrate our fast and accurate inspection systems to a wider audience including test engineers and product designers,” said Shuichi Imai, Sales General Manager for Europe at Yamaha Robotics. “Our latest innovations provide state of the art quality control that can be easily programmed and operates at the line speed to maximize productivity.”

1 STOP SMART SOLUTION

Yamaha has a comprehensive portfolio of high-speed inline surface-mount equipment that also includes screen printers and mounters, collectively known as the 1 STOP SMART SOLUTION. With highly automated features including product-program changeover and printer stencil change, the machines all work together to handle high-mix manufacturing that demand flexibility, as well as high-volume work that calls for sustained high placement speed and high accuracy.

In addition, YSUP smart-factory software connects all Yamaha machines in the line and provides graphical tools for programming, optimizing, and monitoring equipment status and production performance. The software also includes YSUP-LINK, which connects equipment on the factory floor with enterprise systems to enable intelligent manufacturing.

-25 November 2024-