ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

AI Technology Controls FA Equipment in Real Time

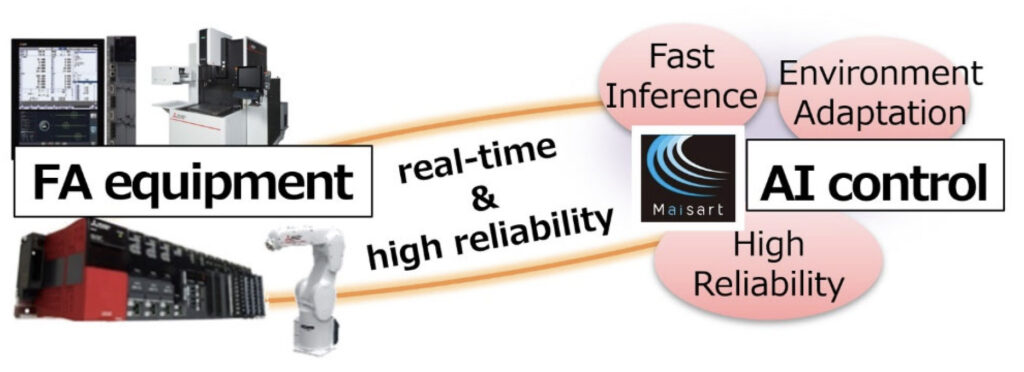

Mitsubishi Electric Corporation and the National Institute of Advanced Industrial Science and Technology (AIST) have developed an AI technology that predicts changes during automated manufacturing processes. It then makes real-time adjustments in the factory automation (FA) equipment, such as motion speeds during operation. The new AI technology also estimates the confidence level of inferences regarding factors, such as machining error, and then controls the FA equipment based on suitable levels of confidence. The technology is expected to lead to more stable, reliable and productive operations, particularly in agile manufacturing.

Key Features of AI Technology

Fast inferences

The AI achieves high-speed inferences for dynamic control of FA equipment in factories being used for agile manufacturing. This includes computerized numerical controller (CNC) cutting machines and industrial robot. The technology controls movements, operating speeds, acceleration of the equipment as they vary during the operating processes. In conventional manufacturing, skilled workers must adjust the operating parameters according to various specifications, like the required level of accuracy.

Mitsubishi Electric has now developed an AI technology that simultaneously performs high-speed inferences and equipment control for real-time FA operation. Incorporating its expertise as an FA equipment manufacturer, the low-load AI control technology performs inferences while simultaneously controlling FA equipment. Although the technology minimizes its processing load, it is capable of achieving high-level inference accuracy while simultaneously guiding FA equipment control.

Adaptable

The shapes of workpieces change during manufacturing and this can lengthen manufacturing times or lower processing quality. Also, changes can vary by workpiece, making it difficult for FA equipment to learn in advance. The new technology, however, allows the AI to learn work factors during FA equipment operation and make real-time adjustments as needed. In addition, the technology formulates physical phenomena, such as friction. It then incorporates these mathematical expressions to enable learning during operation. Thus, making it possible to adapt to constantly changing processing factors.

Reliable

AI inferences must be reliable to ensure that real-time control of FA equipment leads to stable product quality and efficient processing. Mitsubishi Electric’s new algorithm calculates the confidence level of inferences by learning the machine characteristics of each process and target device. By using this algorithm to control FA devices, the new AI ensures high reliability.

Development Background

Operating needs change frequently in agile production. So optimum conditions, such as FA equipment motion speeds, revolutions must be adjusted individually for each type of product. Performing such adjustments manually, however, requires labor and time, resulting in decreased productivity. Moreover, declining birthrates and aging populations in developed countries result in shortage of skilled workers capable of adjusting FA equipment.

In response, Mitsubishi Electric and AIST have developed a technology that uses AI to predict various changes in manufacturing processes, like changes in shapes as each workpiece is machined. Then, it automatically adjusts the FA equipment’s operation in real time. In addition, the confidence levels of the AI inferences are indexed. Also, the FA equipment is controlled accordingly, ensuring high reliability and productivity.

This is the latest deployment of an AIST AI technology in Mitsubishi Electric’s FA equipment. The two entities began collaborating on AI development in fiscal 2017. Going forward, Mitsubishi Electric expects to increasingly incorporate various forms of its Maisart AI technology in FA equipment and systems to significantly improve manufacturing productivity.

Maisart encompasses Mitsubishi Electric’s proprietary artificial intelligence (AI) technology, including its compact AI, automated-design deep-learning algorithms and extra-efficient smart-learning AI. Maisart is an abbreviation for “Mitsubishi Electric’s AI creates the State-of-the-ART in technology.”

AI Control Technology Application Samples

Fast inferences

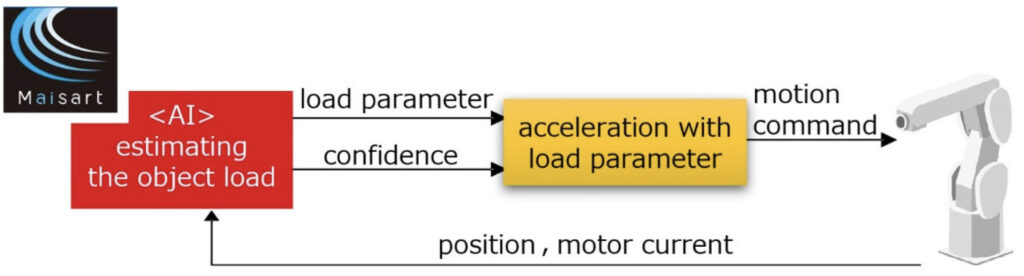

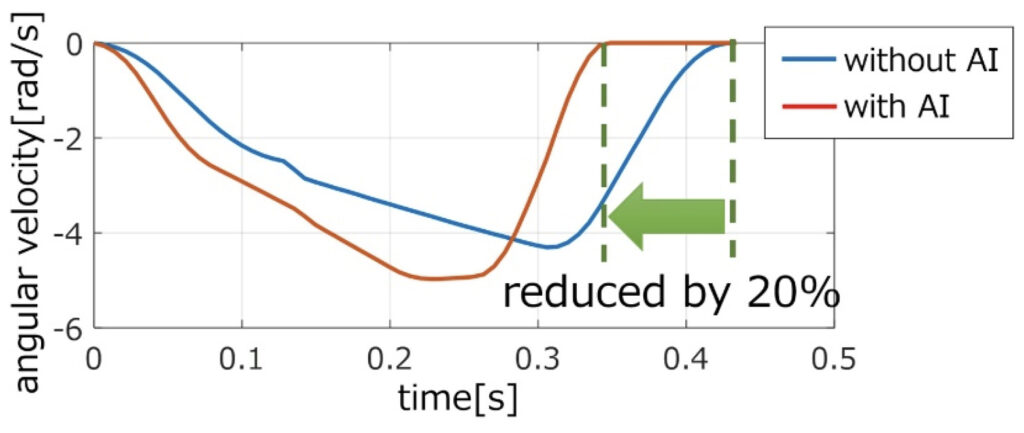

The company developed a solution to estimate loads on robotic arms as an example of the high-speed inference of its AI control technology. Various load parameters are used to calculate acceleration and deceleration speeds. Then, the AI function quickly infers load values using information about the robot, such as motor current, joint angle, and others. Simultaneously, the confidence levels of the inferences are calculated. Finally, acceleration and deceleration are adjusted based on estimated values and confidence levels (Fig. 1-1).

To evaluate its effectiveness, a validation test was conducted to compare differences in robot motion when using and not using load inferences. As shown in Fig. 1-2, robot operation time was confirmed to be reduced by 20 percent when inferences were used. Moreover, more stable operation was achieved by adjusting robot motions only when the confidence level was high.

Adaptation to changing conditions

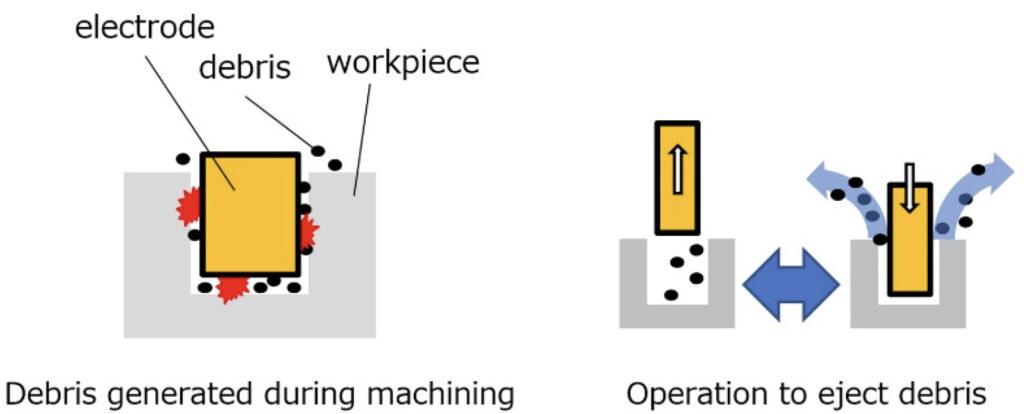

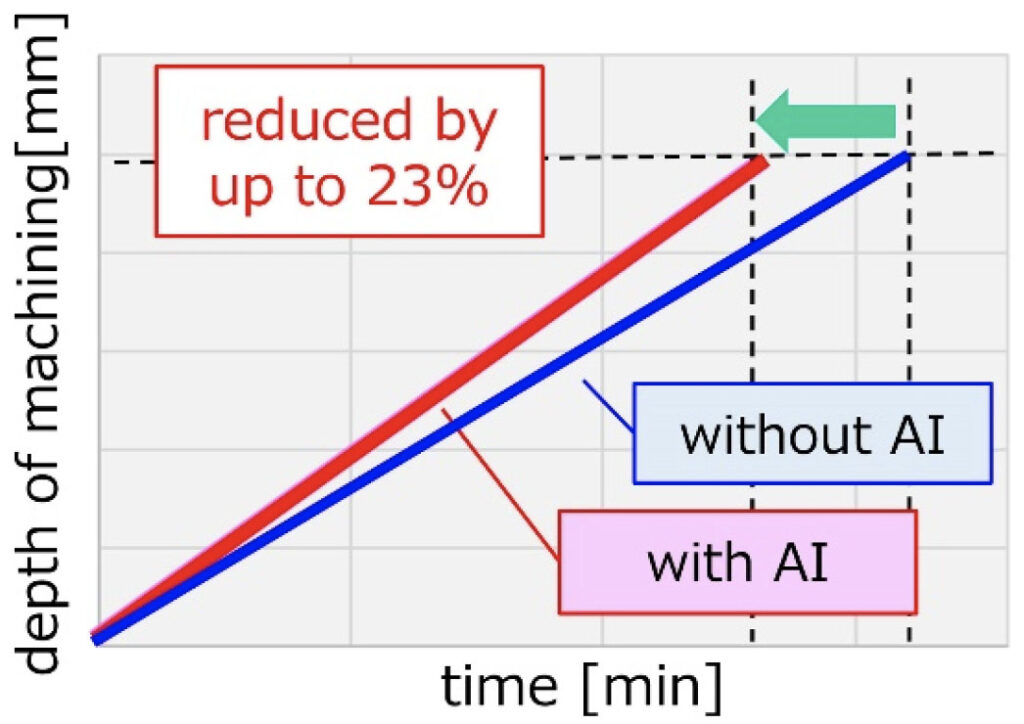

Mitsubishi Electric has developed a solution for automatically adjusting an engraving electric discharge machine (EDM). The EDM positions an electrode close to the workpiece and generates an electric discharge to perform engraving. Debris produced during machining, however, must be ejected with the electrode (Fig. 2-1). As the amount of debris increases as processing proceeds, so the frequency of debris ejection must be increased. In the new solution, AI learns state of debris ejection that is produced, then automatically adjusts the frequency of ejection. Tests have confirmed that machining time is reduced up to 23 percent compared to processing without AI adjustment (Fig. 2-2).

Reliability

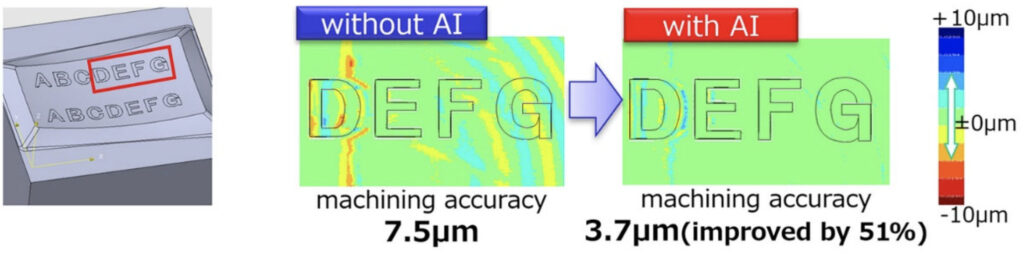

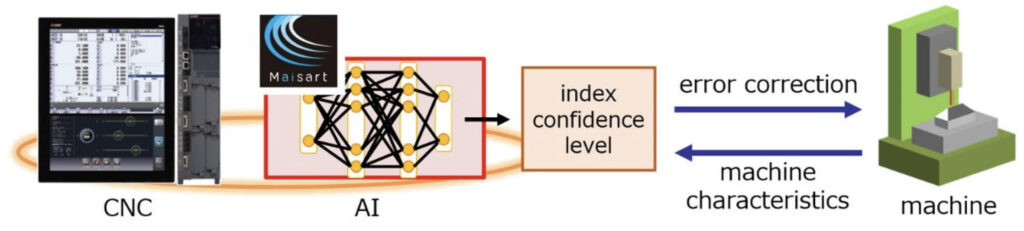

The company developed an AI error-correction solution for CNC cutting machines (Fig. 3-1) as an example of the reliability of the AI control technology. The AI estimates constantly changing machining error to enable correction even during dynamic machining. Also, the confidence levels of the AI’s error inferences are indexed to ensure that error correction is performed only if the confidence level is suitably high.

Tests confirmed that machining accuracy is improved by 51 percent compared to using error correction not supported with AI (Fig. 3-2). Furthermore, low confidence levels can be improved through relearning.