ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

SMT-ELS Makes Big Push at Japan’s JISSO PROTEC

At the recent JISSO PROTEC2022, Japan Robot Association (JARA) highlighted the latest trends in the production and manufacturing field. Incidentally, JARA’s spearheading the said event coincided with its 50th founding anniversary.

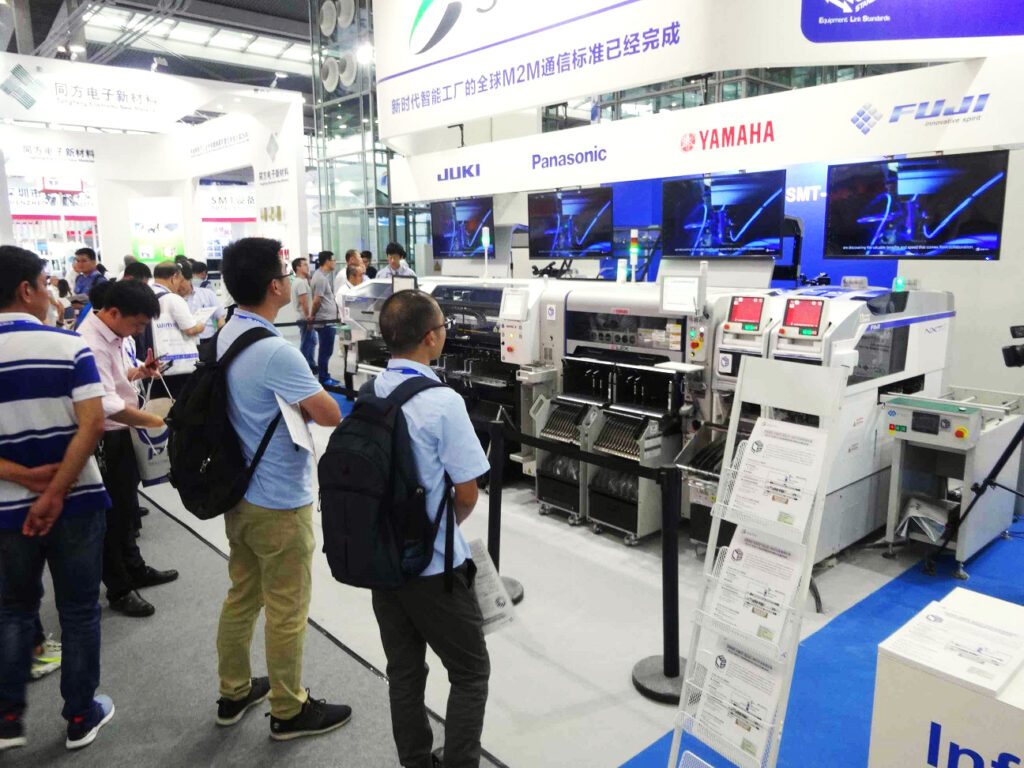

JARA organized the three-day JISSO PROTEC2022, which started June 15. In addition, the organization also conducted demonstrations and held seminars. Most importantly, it made sure the event’s seminars made comprehensive discussions on crucial industry topics and trends. These include SEMI Surface Mount Technology-Equipment Link Standards (SEMI SMT-ELS) and machine-to-machine (M2M) communications standards for surface mounting technology (SMT) lines.

Propels ELS as Standard

The SMT-related event JARA organized was the first after three years. Understandably, JARA made sure this year’s JISSO PROTEC2022 was a significant one.

To illustrate, JARA showcased a sophisticated mounting line, which consisted of working machines, as one of the special exhibitions to mark their anniversary. Best of all, it highlighted the ELS M2M standard designed for smart factories. JARA and the Semiconductor Equipment and Materials International (SEMI) have been working together to promote the ELS.

JARA and SEMI, along with other SMT players, established in 2018 the ELS standard. Here, ELS aims to ensure communication between printed circuit boards, automated model changeover, and inspection equipment among various machines.

In other words, industry players target to make ELS an international standard. For that reason, they have been promoting the standards through exhibitions not just in Japan but in other countries as well.

JARA’s booth at JISSOPROTEC2022 demonstrated SMT line that connects working machines and software from 10 manufacturers via the ELS. Thus, showcasing smart systems using the ELS. JARA’s demo highlighted the linkage of each equipment on the production line for horizontal communication. In addition, it also showed the linkage for vertical communication with the host.

Reduces Labor, Installation Costs

On the SMT line, the ELS carries out feedforward and feedback based on simultaneous transfer of products and data via M2M communications. Thus, it supports the management of the three layers of the SMT line, local host, and factory host.

The standard allows users to freely select machines regardless of brand when installing equipment in factories. Hence, it reduces labor and cost of matching different communications specifications at the time of introduction and installation.

Furthermore, it also supports existing machines. This enables manufacturers to achieve smart factories using assets they currently possess.

SMT equipment manufacturers can easily achieve M2M connection with each peripheral equipment, leading to reduced labor and installation costs. For manufacturers, their local hosts can support SMT lines consisting of their machines and other manufacturers’ machines. Thus, the value of their local hosts is enhanced.

For peripheral equipment manufacturers, development of different protocols has not been a requirement. Particularly, third party manufacturers can handle machines after the local host. Similarly, the same goes even if any mounter from other manufactures adopts ELS.