ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Yamaha Adopts Cross-Sell to Give SMT Business a Boost

On top of the 1-STOP SMART SOLUTION in the surface mount technology (SMT) business, Yamaha Motor Co., Ltd. has been building up cross-sell strategy to boost sales performance. Specifically, Yamaha now offers factory automation machines and products of Yamaha Robotics Holdings Co., Ltd. (YRH) to its own customers.

YRH is a group company of Yamaha and was inaugurated in July 2019 through business integration. Primarily, it targeted the merger of semiconductor back-end processes and mounting of electronic components. Meanwhile, YRH has as its group companies SHINKAWA LTD. on semiconductor bonding, APIC YAMADA CORPORATION on molding equipment, and PFA Corporation on semiconductor inspection systems.

1-STOP SMART SOLUTION

Yamaha has been promoting 1-STOP SMART SOLUTION under the full-lineup system. It enables construction of a mounting line consisting only of Yamaha brand machines for the main equipment. These include mounters, solder printers, printed circuit board inspection systems or solder paste inspection (SPI) and automated optical inspection (AOI) system, surface mount devices (SMD) storage systems or automated components warehouses, and dispensers.

For its FA business, the company has been developing and manufacturing various industrial robots necessary for automated production line. These include single-axis robots, SCARA robots, articulated robots, and linear conveyors. The company also plans to bring to market a collaborative robot (cobot) by the end of the year.

At JISSO PROTEC2022 held in Tokyo in June, Yamaha highlighted the 1-STOP SMART SOLUTION concept. The company demonstrated the YRM20 high-efficiency mounter with 115,000cph. It also showcased YSM20R, YRi-V three-dimensional (3D) hybrid optical AOI system, and YRH10 hybrid placer. The company also introduced a new software YSUP, which plays a pivotal role in Intelligent Factory.

Market Situation

“Although there are concerns, such as the effects of lockdown in China and shortages of semiconductors and components, high level orders have been continuing since last year,” says Ayako Egashira, Executive General Manager of Robotics Business Unit, Solution Business Operations of Yamaha. Egashira oversees Yamaha’s SMT business.

“Thus far, we have expanded our business drawing on the ability to construct an SMT line using only Yamaha brand machines. Advancing further, we now promote cross-selling. (Through this process,) group companies operate in a cross-sectional manner beyond the framework of products and regions. Companies use each other’s sales networks. Specifically, we sell the YRH Group companies’ products, Meanwhile, YRH Group companies handle our products. With a strategy like this, we have been strengthening business through synergy from cross-selling,” said Egashira.

To support cross-selling, Yamaha has opened showrooms with laboratory function at YRH in Suzhou and Shenzhen in China, in Taiwan and in Thailand. The company has already started using each other’s showrooms.

In anticipation of the expansion of its robotics business in the future, Yamaha also steps up its production system. In relation, the company will expand and renovate the Hamamatsu Robotics Office, which is the production base of robotics. It is in Japan’s Shizuoka Prefecture. The company targets to start the operations of the facilities within FY2024. Upon completion, the production area will increase to 1.8-fold of the present facilities.

Propose Intelligent Factory

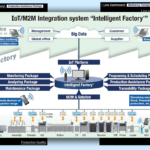

Through the interconnection of SMT, FA, and semiconductor backend processes, Yamaha is fully enabled to propose one-stop solution to SMT. It can build on the strength to provide main equipment from bonding and molding in the semiconductor backend processes, to assembly of camera modules.

Furthermore, the company also intends to accelerate the proposal of Intelligent Factory, an integrated system of internet of things (IoT) and machine-to-machine (M2M). Intelligent Factory aims to achieve labor savings and optimization of the entire factory.