ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japanese SMT Makers Roll out New Models, Advance Automation

Japanese surface-mount technology (SMT) manufacturers aggressively roll out new models that pave way for factory automation. They actively participated in recent SMT-related trade events to promote their latest machines. On top of increasing machine demand, manufacturers also focus on the potential of the China market amid the reversal of its zero-COVID restrictions.

SMT manufacturers showcased their machines and technologies at trade-related events. In January, NEPCON China drew about 75,000 visitors during the three-day event. Around the same time, IPC APEX EXPO 2023 gathered together exhibitors from the electronics manufacturing industry, in San Diego, California. Manufacturers from all over the world, including North, Central, and South Americas, India, Korea, and countries in Europe, came to participate. The event attracted a record number of visitors, according to IPC, who organized the event.

The Chinese market accounts for 60 to 70 percent of the sales of Japanese SMT manufacturers. Although the geopolitical risk of China is a concern, manufacturers continue positioning China as an important market. Specifically, they put hope on the expansion of China’s domestic demand as the country eases its zero-COVID restrictions.

Business in 2023 Gets into Full Swing

Buoyed by notable events, SMT manufacturers started their businesses in 2023 on a positive note.

THK Co., Ltd. provides linear motion (LM) guides and other products to mounter manufacturers. According to Akihiro Teramachi, President and Chief Executive Officer of THK, said, “In China, we have put in place a system for increased production. Specifically, we completed the construction of additional factory buildings at THK Manufacturing of China (Changzhou) Co., Ltd. in Changzhou, Jiangsu Province; and THK Manufacturing of China (Liaoning) Co., Ltd. in Dalian, Liaoning Province.”

“Following the reversal of zero-COVID restrictions (in China), consumer spending has recovered. Also, manufacturers are expanding their investments in plants and equipment. Our company started receiving increasing inquiries since the end of the Lunar New Year,” continued Teramachi with optimism on the Chinese market.

Meanwhile, officials at FUJI Corporation bank on the potential of domestic demand. Joji Isozumi, Board Member, and Executive Officer at FUJI said, “Although there are risks in China, the scale of China’s domestic demand is large. Our company will continue to bolster production at the Kunshan Plant.”

He also notes sustained investments from the automotive and communications industry. “On the manufacturing front, automotive and communications-related manufacturers steadily invest in plants and equipment,” said Isozumi.

Meanwhile, Akira Kiyohara, Representative Director Chairman & Chief Executive Officer at JUKI Corp. highlighted a more globalized business approach. He said, “We promote borderless business in India, East Europe, and Mexico. (This strategy came) following global companies that have been relocating their production facilities.

“On the other hand, China is a large market of mounters. Therefore, we will continue to put priority on the Chinese market,” he continued. Going forward, the company will continue to put strength into its business in China.

Pitch Latest Machine Models

Moreover, Japanese manufacturers continue to promote new mounter models both domestically and overseas. Consequently, they aim to increase the demand for their mounters.

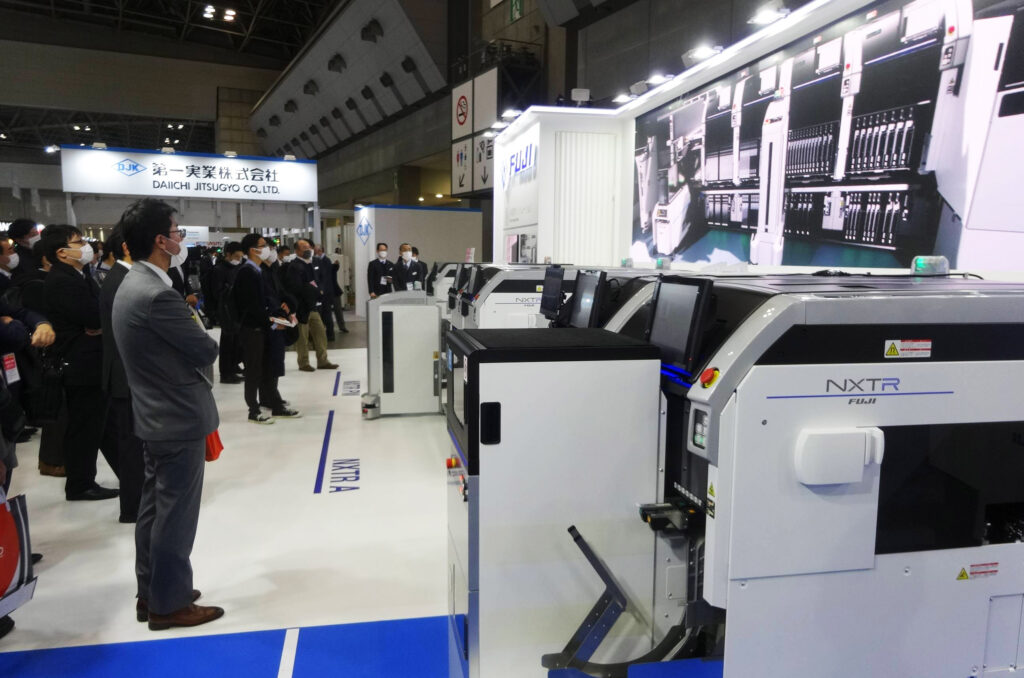

For its part, FUJI positions the FUJI Smart Factory as a new mounting platform. Also, this year, the company has been rolling out the NXTR mounter targeting fully automated production.

Furthermore, the company will start taking orders for the AIMEXR mounter in FY2023. Specifically, this mounter features flexibility and expandability, meeting the needs for variable-mix, variable-volume production.

Moreover, the Process Automation Business Division of Panasonic Connect Co., Ltd. deploys mounters to promote autonomous factories. It defines an autonomous factory as a factory that can quickly respond to changes in the market needs and the supply chain. An autonomous factory also evolves independently.

Panasonic Connect targets to put in place an autonomous platform for its 2023 market offering. The platform will include the NPM-GH mounter and the NPM-GP/L screen printer of the NPM-G Series. An automated components supply system is also set for market release in 2023.

Akihiro Akiyama, Managing Director of the Process Automation Business Division at Panasonic Connect said, “We would like to give an impression by creating the world number one edge device that realizes an autonomous factory, and by offering a new solution business.”

At the core of its robotic business, Yamaha Motor Co., Ltd. promotes the 1-STOP SMART SOLUTION. This smart solution concept comprises of surface mounters, solder paste printers, and automated optical inspection systems under its robotics business. It also includes factory automation (FA) equipment, including linear conveyor modules, and SCARA robots. It also includes products of Yamaha Robotics Holdings Co., Ltd. to the 1-STOP SMART SOLUTION concept.

In April, Yamaha will roll out the YRM20DL, a dual-lane conveyor model of the YRM20 mounter, which the company positions as a platform for the SMT process.

Ayako Egashira, Executive Officer, Executive General Manager of the Robotics Business Unit, Solution Business Operation at Yamaha Motor, said, “We will promote the one-stop solution. Also, we will cross-sell between companies eyeing labor-saving and optimization of the entire factory. In this effort, we add FA and the semiconductor manufacturing back-end process to SMT.”

Looking forward to 2023, the company sees a promising business. “The Chinese market started to regain its agility and investments in electric vehicles (EVs) and power semiconductors became active.”

Meanwhile, JUKI strengthens its mounter business by expanding its share of the high-speed mounter market. In this segment, the company pitches RX-8, which features 100,000cph and rolled out in 2022. Furthermore, under the JUKI Smart Solution, JUKI proposes its entire SMT line, which integrates pre- and post-mounting processes, including the ISM Series automated components warehouses. At the same time, the company also cultivates new application areas of automated warehouses and inspection systems in the non-mounting field.