ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Mitsubishi's New SiC Die to Surge More Superior xEVs

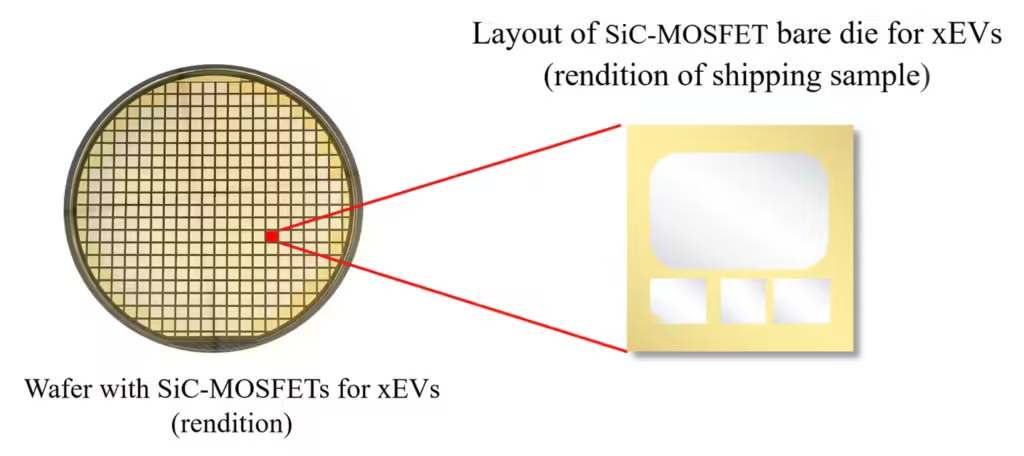

Mitsubishi Electric Corporation will begin shipping samples of a silicon carbide (SiC) metal-oxide-semiconductor field-effect transistor (MOSFET) bare die. Specifically, this will complement the need for drive-motor inverters of electric vehicles (EVs), plug-in hybrid vehicles (PHEVs), and other electric vehicles (xEVs).

Mitsubishi Electric’s first standard-specification SiC-MOSFET power semiconductor chip will enable the company to respond to the diversification of inverters for xEVs. Moreover, it will aim to contribute to the growing popularity of these vehicles.

Proprietary Manufacturing Technologies

The new SiC-MOSFET bare die for xEVs combines a proprietary chip structure and manufacturing technologies. Thus, contributing to decarbonization by enhancing inverter performance, extending driving range, and improving energy efficiency in xEVs.

Meanwhile, Mitsubishi Electric’s new power semiconductor chip is a proprietary trench* SiC-MOSFET. Particularly, it reduces power loss by about 50% compared to conventional planar SiC-MOSFETs.

Thanks to proprietary manufacturing technologies, such as a gate oxide film process that suppresses fluctuations in power loss and on-resistance, the new chip achieves long-term stability. Therefore, contributing to inverter durability and xEV performance.

First to Mass Produce EV Power IC Module

Mitsubishi Electric became the first company to mass produce xEV power semiconductor modules in 1997. Since then, it has introduced numerous power modules that have contributed to improved reliability, including greater heat-cycle resistance, and smaller inverters for various EVs and hybrid electric vehicles (HEVs).

Specifically, the company’s latest generation of widely used T-PMs will now introduce the J3-Series of compact modules equipped with either SiC-MOSFETs or RC-IGBTs (Si). Both uses the same package to enable xEV drive motor inverters to be further downsized.

Mitsubishi Electric, with its comprehensive lineup of power modules covering a wide range of capacity bands for inverters, is committed to extending the driving range and reducing the electricity costs of increasingly popular EVs and PHEVs.

Power semiconductors are increasingly utilized to efficiently convert electric power to lower the carbon footprint. This is true, particularly in heavy industry, where these devices are used in power conversion equipment, like inverters in railway traction systems and for DC power transmission.

Mainly, expectations are high for SiC power semiconductors as they significantly reduce power loss. In addition, power semiconductor modules are used in power conversion devices for large industrial equipment. The demand is expanding for high-power, high-efficiency power semiconductors that help to improve power-conversion efficiency.

12 November 2024