ASIA ELECTRONICS INDUSTRYYOUR WINDOW TO SMART MANUFACTURING

Japan Unix Releases More Soldering Robots

Japan Unix Co., Ltd. has been introducing new models of soldering robots into the market one after another. Besides, the company also provides a rich lineup of software for internet of things (IoT)-enabled soldering robots.

Kentaro Kono, General Manager, Japan Unix Co., Ltd., says, “Even with COVID-19 pandemic, we aggressively advanced the development of new soldering robots. In 2021, we brought them to market. Simultaneously, we have also enriched software that improves ease of use and functions. This year, these new products have begun to contribute to sales.”

“Although Japan and China are still taking cautious measures against COVID-19 infections, businesses have recovered in the United States and countries in Europe. Visits of foreign customers to our company have begun to increase gradually,” added Kono.

Full Automation of Production Lines

Since July 2020, amid the COVID-19 pandemic, Japan Unix has been holding webinars regularly targeting its customers. Recently, the company concluded its Webinar Week 2022 from February 16. Kono said the three-day webinar garnered favorable reception having attracted the largest number of participants ever.

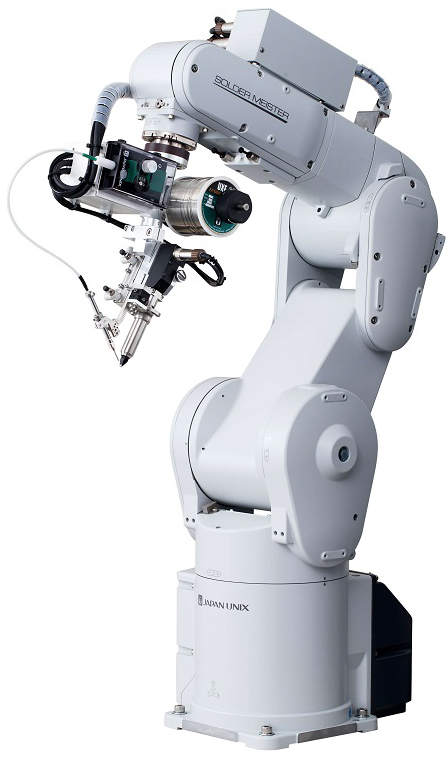

In 2021, Japan Unix started offering the UNIX-HFR multi-axis SCARA soldering robot for inline in the FR Series. Immediately, in the same year, it released the UNIX-VFR vertical inline soldering robot also in the FR Series. They are under SOLDER MEISTER, the top-of-the-line models of soldering robots.

Japan Unix has commercialized the FR Series as a new generation of soldering robots designed for full-automation production lines. The UNIX-HFR features an enhanced communication network function to complement the IoT era. Equipped with an Ethernet communication port, it can send operation conditions to host computer and programmable logic controller (PLC). Furthermore, the UNIX-VFR is capable of three-dimensional (3D) mounting making the most of the characteristics of vertical multi-joint soldering robot. It can also solder mounting surfaces with angles from the most suitable angles.

Japan Unix has equipped all soldering robot models with a communication port to have IoT capability. Besides, the company has also made all its models to support its original soldering robot management software Soldering Manager. The software monitors the conditions of soldering robots, and automatically collects and stores data. Stored operation data can be used in various ways.

Suits SMT Process

As a new product, the company also provides Thermo Pro laser soldering system, which controls temperature using a radiation thermometer. Incorporation of Thermo Pro enables temperature management and control during soldering, in addition to conventional management items, such as output and time, in laser soldering. Accordingly, using Soldering Manager Pro for ULD-02 together with Thermo Pro displays measured temperatures in a graph. In addition, it also allows the storage of temperature and laser output at the time of control as moving images.

In terms of technology, Japan Unix has developed Area Laser, a laser irradiation technology, for soldering robots. It features uniform energy in the laser irradiation area. It can irradiate beams with shapes other than circle, such as square and rectangular. Furthermore, with the development of Area Laser, Japan Unix has expanded the fields where laser soldering robots can suit surface mount technology (SMT) process.

Physical Events

Japan Unix cancelled its participation to exhibitions in 2021 amid the COVID-19 pandemic. However, this year, the company will take part in the Nagoya Edition of NEPCON Japan from October 26 to 28 at Portmesse Nagoya in Nagoya, Japan. Overseas, the company plans to take part in NEPCON China 2022 from May 24 to 26 in Shanghai, China, and NEPCON Asia 2022, from October 12 to 14 in Shenzhen, China.